POWER

-

O&M

Fire Safety in Modern Hydroelectric Stations

It may seem counterintuitive, but fire can be a serious danger in hydropower plants. In some respects, the danger is even greater than in thermal power stations. Most U.S. hydro plants are 30 to 70 years old but can deliver another 20 or 30 years of service with upgrades — including state-of-the-art fire protection systems. The design options outlined here also apply in large part to other generating stations.

-

News

Watertight Temperature Data Loggers

Dickson’s new stainless steel case data loggers are designed to monitor up to 275F in wet conditions. The watertight instruments are made of stainless steel and are available in three models: HT 200 (the "Takes-the-Heat-Watertight" model) and piercing probe models HT 220 and HT 225. All models are available with user-replaceable one-year batteries and USB-enabled […]

-

Hydro

Fast-Tracking a Control System Retrofit

Upgrading a 1970s-era generator control system to new millennium technology in 12 days during a three-week shutdown would require careful planning and teamwork under any circumstances. The quick replacement of the governor and control system at the PT Inco smelter’s hydroelectric generation system is even more impressive because the facility is located in the middle of an Indonesian jungle.

-

News

Abrasion-Resistant Bushing Material

The GRAPHLON GM 860 developed by Graphite Metallizing is an abrasion-resistant bushing material that protects pumps and helps prolong pump life. Designed for use in the manufacture of pump bushings and other critical-wear parts, the tough, polymer/graphite-based material was developed to replace traditional pump materials, which are prone to damage from highly abrasive suspensions. It […]

-

Legal & Regulatory

Transmission Superhighway or Interconnected Patchwork?

President Obama promoted "green energy" as a signature theme in his presidential campaign. During his first weeks, he reaffirmed his administration’s commitment to renewable resources. In a radio address, he promised to double the nation’s alternative energy capacity within three years and to construct a 3,000-mile transmission grid to "convey this new energy from coast to coast."

-

Business

ELECTRIC POWER 2009 Exhibitor Preview

This year’s ELECTRIC POWER Exhibition will feature the latest technologies and services from approximately 500 companies. Get a preview of some of the exhibitor offerings here. For the entire offerings, you’ll have to visit the show floor in Chicago this May. (You’ll find all the event information here.)

-

Distributed Energy

In Search of Perfect Power

What do you do when your research institution is losing roughly half a million dollars annually as a result of multiple electricity outages — and electricity demand keeps rising? If you’re the Illinois Institute of Technology, you turn the challenge into a campuswide learning experience by teaming with the Galvin Electricity Initiative and other experts to design and construct a prototype Perfect Power System (PPS). Even during its implementation, the PPS promises to provide more reliable and sustainable electricity to the university at a lower cost than it had been paying.

-

Proposed Federal RPS Needs Rewrite

A 16% national RPS would require almost a 500% increase in renewable generation in the next decade, or about 32,000 MW. EIA data show that the U.S. had about 8% renewables online at the end of 2007. What’s worse is that very few existing projects would count toward the requirements of this proposed legislation.

-

Nuclear

Toshiba Completes EPC Negotiations for STP

The pace at which next-generation nuclear power is developing in the U.S. accelerated this February as the U.S. arm of Toshiba inked an engineering, procurement, and construction (EPC) agreement with an advanced boiling water reactor (ABWR) nuclear development company jointly owned by NRG Energy and Japan’s Toshiba Corp. The agreement seeks to ensure that the two ABWRs planned to expand the South Texas Project (STP) in Bay City, Texas, will be constructed on time, on budget, and to exacting standards.

-

O&M

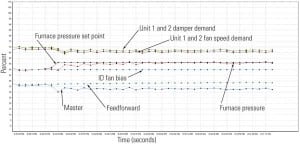

Boiler-Tuning Basics, Part I

Tuning power plant controls takes nerves of steel and an intimate knowledge of plant systems gained only by experience. Tuning controls also requires equal parts art and science, which probably is why there are so few tuning experts in the power industry. In Part I of a two-part series, we explore a mix of the theoretical and practical aspects of tuning boiler controls.