Focus on O&M

-

O&M

Computer-based hydro plant scheduling

Hydroelectric power plant managers face unique scheduling challenges. They have a finite amount of water in their reservoirs available for energy production, and they need to schedule generation according to market demand to maximize profits from their limited “fuel” supply. Hydro power plants are capable of producing products other than electricity. Among them are ancillary […]

-

O&M

Monitor your fluid levels online

Although fluid monitoring technology has come of age in recent years, its level of sophistication varies widely across industries. Some users of bulk chemicals, fuels, and other fluids use state-of-the-art systems with bells and whistles like automated data gathering and transmission. At the other extreme, some tank farms still “stick the tanks.” Although 95% of large […]

-

O&M

Standardizing PdM, fleetwide

The pressure on power producers to supply reliable electricity is unyielding. Forced outages, which usually are caused by unexpected component failure or systemic problems, can prove very costly to both bottom line and reputation. To reduce the frequency and duration of unscheduled outages, many gencos are implementing comprehensive predictive maintenance (PdM) programs. Such is the […]

-

Water

Focus on O&M (May 2006)

Desalination, Italian style; How to minimize DI operating costs; Advanced flow meter works with shorter pipe runs; Why tubing beats piping.

-

O&M

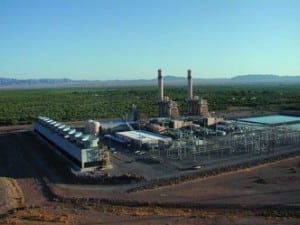

SWAT team helps shorten forced outage

Calpine Corp.’s South Point Energy Center in Mohave County, Ariz. (Figure 1) is a 520-MW natural gas-fired, combined-cycle facility with two Siemens Westinghouse 501FD gas turbines and one steam turbine-generator with a BB33 high-pressure (HP) section, a BB65 intermediate-pressure section (IP), and a 65CC intermediate/low-pressure (LP) section. The plant entered commercial service in June 2001. […]

-

O&M

Wireless vibration monitoring shows benefits

The 1,768-MW Baldwin Energy Complex in Illinois was the site of a joint-venture pilot project to demonstrate a wireless vibration-monitoring system for a coal pulverizer. The partners in the project were EPRI and the plant’s owner, Houston-based Dynegy Midwest Generation. A key objective of the project was to identify a reliable wireless system capable of […]

-

O&M

How important is IR detector resolution?

Stretching meager maintenance dollars is a way of life for most maintenance staff. In past years, the cost of an infrared (IR) camera usually came down to a choice between a low-resolution 160 x 120-pixel camera or no camera at all. If the camera was chosen, it usually became clear before long that low resolution […]

-

-

News

A breakthrough in hydroturbine design

One of the distinguishing characteristics of deregulated power markets is variable demand. The ability to operate efficiently at partial loads can determine whether a plant is profitable or not. This need creates special challenges for hydroelectric turbines, because at partial loads they often exhibit strong swirl in the draft tube at the outlet of the […]

-