Focus on O&M

-

O&M

Predictive Maintenance That Works

This is the fourth in a series of predictive maintenance (PdM) articles that began in the April “Focus on O&M” with an introduction to PdM as a process whereby maintenance is performed based on the condition of the equipment rather than on a predetermined interval. In the May and July issues, we began exploring specific PdM techniques, such as motor-current signature analysis and oil analysis.

-

O&M

JEA Increases Power Output Through CFB Improvements

JEA’s Northside Generating Station in Jacksonville, Fla., Units 1 and 2 were built in 1966 and 1972, respectively, although the Unit 2 boiler had not operated since 1983. Both were heavy oil– and natural gas–fired steam units rated at about 300 MW. The utility “repowered” those two units by removing the old boilers and adding new circulating fluidized bed (CFB) boilers (Figure 1) that entered service in 2002. At that time, they were the world’s two largest CFBs, and the plant won POWER’ s Plant of the Year Award.

-

O&M

Applying Acoustic Pulse Reflectometry in a Geothermal Plant

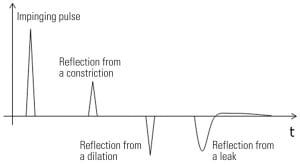

Acoustic pulse reflectometry (APR) is a tube inspection method that has been gradually gaining acceptance as a tool for heat exchanger inspection. Different types of heat exchangers operating in different operating environments have different failure mechanisms, making some of them more suited than others for inspection by APR. Finned tube heat exchangers are a typical example of heat exchangers particularly conducive to APR inspection.

-

O&M

Advanced Coatings Protect Plant FGD Systems

Now that many flue gas desulfurization (FGD) systems are reaching middle age, corrosion repairs of structural and process vessels are becoming more common. Corrosion is caused by condensates of acids formed during the FGD process, which accelerate pitting and crevice corrosion, particularly in scrubbers where high sulfate solutions are present. Scrubbers lined with 2205 duplex stainless steel are among the most vulnerable to pit or crevice corrosion, from both chlorides and fluorides.

-

Instrumentation & Controls

NERC CIPS Update: The Advantages of an Integrated Factory Acceptance Test

When adding, modifying, or upgrading a system, many critical infrastructures conduct a factory acceptance test (FAT). A FAT includes a customized testing procedure for systems and is completed before the final installation at the critical facility. Because it is difficult to predict the correct operation of the safety instrumented system or consequences due to failures in some parts of the system, a FAT provides a valuable check of these safety issues. Similarly, because cyber security can also impact the safety of critical systems if a system is compromised, it makes sense to integrate cyber security with the FAT.

-

O&M

Systems Integration, Flexible Control Reduce Makeup Water Cost

Longview Power, a 695-MW coal-fired power plant now under construction in Maidsville, W.Va., is scheduled to begin commercial operation later this year. The $2 billion project reached 580 MW in early June, just a month after completing the “first fire on coal” schedule milestone. Testing and tuning of the controls and various systems continue.

-

O&M

Improving the Efficiency of Toronto’s District Heating Plant

Enwave Energy Corp.’s district heating plants in downtown Toronto will be operating cleaner and more efficiently before the fall 2011 heating season begins when boiler upgrades now under way are completed. Enwave hired Benz Air Engineering (BAE) to design and install upgrades to all eight boilers inside Enwave’s Pearl Street Station. When the $20 million project is completed, the retrofits will produce energy savings exceeding $5 million per year. In addition, the company will receive incentives of $100,000 per boiler from Enbridge, its natural gas provider.

-

O&M

Fighting Pipe Abrasion

Steel piping systems used to convey coarse materials, often over long distances, are under constant attack from abrasion. In power plants, the materials are usually coal and limestone slurry. The common industry solution has been to install abrasion resistant (AR) pipe that is much harder on the Brinnell Scale than standard steel pipe. The harder the inner wall, studies have shown, the better it resists the gouging or plowing action of abrasive sliding particle flow.

-

O&M

Texas Competitive Model Spreads to Pennsylvania and Illinois

A record 400 attendees participated in KEMA’s 22nd annual Executive Forum in San Antonio, Texas, in late April to debate and discuss the “retail resurgence” of competitive electricity sweeping America.

-

Business

New Opportunities Abound for Retail Electric Suppliers

Following the conclusion of the KEMA conference (see previous story), Mark Axford had the opportunity to talk with Phillip Tonge, recently appointed president of Spark Energy LP. Spark Energy is a retail energy provider (REP) of electricity and natural gas in 16 states that have opened their markets to competition for industrial, commercial, or residential customers.