Focus on O&M

-

O&M

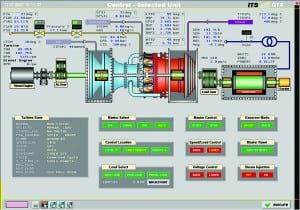

Focus on O&M: Replacing Multiple Turbine and BOP Control Systems with a Single Platform

Termoyopal, a utility based in Bogota, Colombia, recently repowered its power plant at Yopal, Colombia, by replacing three gas turbines with refurbished units and upgrading the remaining two turbines. The

Tagged in: -

O&M

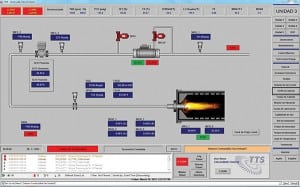

Considerations When Upgrading Gas Turbine HMIs

Aging human machine interface (HMI) hardware will eventually become a burden on plant operation. Obsolete HMIs can cause problems with connectivity, historical data loss, and hardware failure. As the hardware

Tagged in: -

O&M

Improve Plant Heat Rate with Feedwater Heater Control

Meaningful, yet often hidden thermal performance losses occur in feedwater heaters.

-

O&M

Industrial Wireless Sensors: A User’s Perspective

There are many reasons to anticipate that the use of wireless instrumentation in industrial settings will increase dramatically in the next few years.

-

O&M

LADWP Harnesses LMS100 to Solve Once-Through Cooling Dilemma

Los Angeles sits alongside the world’s largest body of water, and naturally the city’s Department of Water & Power (LADWP) placed its generating stations along the shoreline to take advantage of that abundant resource for cooling. The LADWP built three coastal generating stations that provide the city with 2,162 MW, about 35% of the peak annual demand.

-

O&M

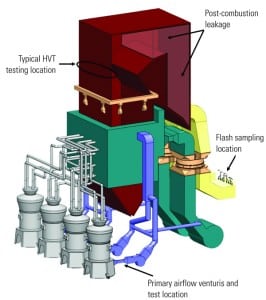

Performance-Driven Maintenance

My career began as a results engineer testing large utility boilers. Ever since that first assignment, I have remained interested in the details of how the measurement and control of the furnace fuel and air inputs can make a huge difference in overall boiler performance. Given that plant operations and maintenance (O&M) budgets are slimmer today than in recent memory, my experience is that targeted performance testing can provide important feedback for prioritizing maintenance expenditures. The combination of plant testing and targeted O&M expenditures provide the best opportunity for efficient and reliable plant operations. I call this approach to plant efficiency improvement “performance-driven maintenace.”

-

O&M

Lithium-Ion Batteries: A Potential Fire Hazard

The proliferation of battery technologies in modern industry is presenting fire professionals with new sets of challenges. Confusion exists as to the correct approach for protecting industrial batteries from fire, whether that be in battery manufacturing, battery storage, or battery-powered applications.

-

O&M

Battling White Rust

Does your power plant use a chiller for combustion turbine inlet air cooling or other processes that reject heat? If so, there is a good chance you also have an auxiliary cooling tower or a wet surface air cooler to cool these systems.

-

O&M

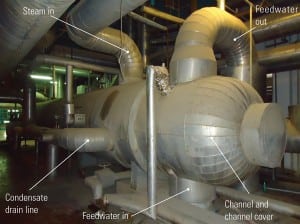

How to Avoid Feedwater Heater Drain Design Pitfalls

Feedwater heaters are used to preheat boiler feedwater by condensing steam extracted from several stages of the steam turbine. Feedwater heaters enhance the thermal efficiency of the power plant by reducing the amount of fuel burned in the boiler to produce a specified power. At the same time, the steam energy extracted from the turbine by the feedwater heater helps to reduce the rate of energy rejection to the environment via the condenser.

-

Instrumentation & Controls

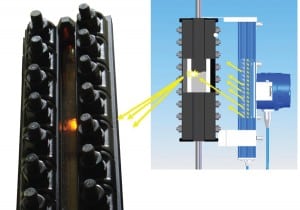

Drum Level Instrumentation Update

Accurate knowledge of the water level in any boiler drum application is an absolute necessity. While operating a boiler with low water level is one of the leading causes of boiler failure, operating with a high water level may produce less-than-optimal steam, as well as damage to the steam turbine by moisture carryover.