Focus on O&M

-

O&M

Inlet Air Cooling Systems Improve Gas Turbine Performance

An inlet air cooling (IAC) system offers one of the most cost-effective ways to improve gas turbine (GT) performance—especially during the peak hours of hot summer months. After all, GT output depends on

Tagged in: -

O&M

Newly Designed Deluge Valve Improves Functionality

Stanwell Power Station, a 1,460-MW coal-fired power plant located in Queensland, Australia, faced a dilemma. The reliability of its fire protection system was questionable. Many of the plant’s multiple jet

-

O&M

Dissimilar-Metal Weld Is a Misnomer

Most combined cycle professionals understand that a joint between grade 91 steel and an austenitic stainless steel is considered a dissimilar-metal weld. For that reason, it requires special welding

-

O&M

Using Rotor-In Major Inspections to Shorten Outages and Drive Safety

Today, some F-class operators continue to opt for rotor-out major inspections, which are cumbersome and inefficient. They involve complex lifts and moves of the rotor, as well as the need for substantial space

-

O&M

Eddy Current Tube Inspections Efficiently Find Defects

Eddy current testing is a well-established method of nondestructive testing that is used to examine nonferrous/nonmagnetic materials such as condenser and heat exchanger tubes in power generation plants. Eddy current testing reveals discontinuities in tubing, provides plant engineers with an accurate assessment of a unit’s condition, and is a tool for predicting the remaining useful […]

Tagged in: -

Connected Plant

Protecting Critical Infrastructure

Society is highly reliant on the safety and stability of critical infrastructure. From boiling a kettle to maintaining national security, an interruption in the electricity supply can cause serious damage to

Tagged in: -

O&M

Proper Scaffold Access Plan Helps Reduce Radiation Exposure

Pipes, valves, turbines, pumps, condensers, and other mechanical components in the radiologically controlled area (RCA, or hot side) of a nuclear power generation facility require routine inspection, testing, maintenance, and, eventually, replacement or repair. When technicians need to work at height, erecting a scaffold often provides the safest and most effective method of access. This […]

Tagged in: -

Legal & Regulatory

Counterfeit Parts: Why Authenticity Is Imperative

When it comes to running a power plant, it’s easy to take the little things for granted. Yet it’s the little things that often have the greatest impact on plant managers’ ability to deliver reliable service for their customers. Take power, for instance. Plant managers are focused on bringing power to their customers. But are […]

Tagged in: -

O&M

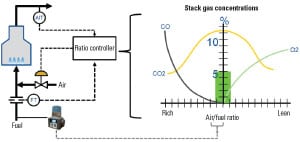

Gas Chromatographs Offer New Technology for Power Plant Burner Control

Background burner control is critical for power and industrial plants because it affects emissions, energy costs, and process efficiencies. For natural gas burners, variations in gas composition can have a

Tagged in: -

O&M

Boiler Cleaning with Shock Pulse Generators

Increasing plant efficiency and reducing maintenance costs is important for economic power plant operation. One part of the task involves keeping the boiler heating surfaces as clean as possible, which increases heat transfer, reduces maintenance, and avoids unplanned standstills of the plant. Shock pulse generators (SPGs) are an innovative and efficient way to manage boiler […]

Tagged in: