Features

-

O&M

Wind Turbine Generator Maintenance: What to Expect and Why

Over the past few years, wind generation projects have become prominent features of the North American landscape and of the utility infrastructure. In spite of their variable production load onto the grid

-

O&M

Coal-Fired Power Plant Heat Rate Improvement Options, Part 2

In recent years several EPRI projects have explored different aspects of heat rate improvements. This article, following Part 1 in the November 2014 issue of POWER , reviews results of implementing heat rate

-

O&M

Assessing and Prioritizing Structural Repairs to Material-Handling Systems

Material-handling systems at coal-fired power plants operate nearly continuously in harsh conditions for decades. Temperatures, moisture, overload conditions, and collisions from equipment can take a toll on

Tagged in: -

Coal

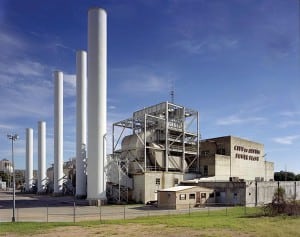

Tricky Business: Taking Down Old Coal Plants

Austin, Texas, is one of the hottest real-estate markets in the U.S. One of the prime new properties in the Texas capital is Seaholm, a $130 million project on some eight acres of prime downtown land

-

Coal

Construction Considerations Are Key in Closure Planning for Coal Ash Ponds

Closure and remediation solutions for coal ash ponds, or impoundments, vary greatly. Assuming the U.S. Environmental Protection Agency (EPA) promulgates the expected proposed Subtitle D regulations, technical

-

Gas

Repowering Erbil Power Project Adds 500 MW to Kurdistan Grid

After building three 1,000-MW dual-fuel simple cycle plants, each with eight combustion turbines, Mass Global Holding Ltd. recently repowered the Erbil Gas Power Station, located in Iraqi Kurdistan, using vertical heat recovery steam generators, adding 500 MW of capacity to the local grid. Iraqi Kurdistan, located in the northeast corner of Iraq, is nation […]

Tagged in: -

Coal

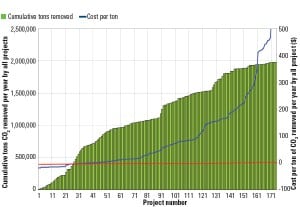

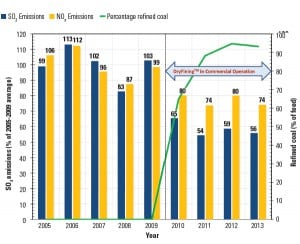

Improve Plant Efficiency and Reduce CO2 Emissions When Firing High-Moisture Coals

Improving efficiency at existing coal-fired power plants anywhere in the world is a path of no regret: A more efficient power plant uses less coal, has lower emissions, and experiences lower variable costs. Great River Energy’s Coal Creek Station has demonstrated that by recycling low-grade waste heat with DryFining, it can reduce emissions, including CO2, […]

Tagged in: -

Gas

Gas Peakers with Clutches Power Bakken Oil Boom

With rapidly growing electricity demand from North Dakota’s booming shale oil industry, Basin Electric Power Cooperative needed flexible peaking generation in a hurry. Two stations equipped with LM6000 turbines and clutches are providing both peaking and reactive power. U.S. electricity production has been flat for the past decade, hovering between 3.9 billion MWh and 4.1 […]

-

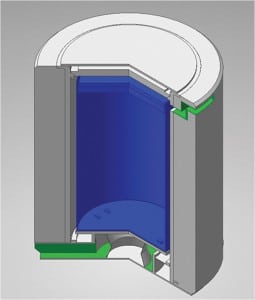

Nuclear

Spent Nuclear Fuel: Is Off-Site Storage Now Off the Agenda?

The Nuclear Regulatory Commission’s recent “waste confidence” ruling, which declares storage of spent fuel at reactor sites safe indefinitely, could fundamentally undercut the decades-long U.S. policy of seeking an off-site, permanent burial site for high-level nuclear waste. A five-decades-old goal of the U.S. nuclear power industry, its regulators, and the Department of Energy (DOE)—permanent, off-site […]

Tagged in: -

O&M

Boosting Efficiency with a Sootblowing Optimization System

Too-frequent sootblowing can damage boiler components and place a big load on plant efficiency, but not enough of it can be just as big a problem. A sootblowing optimization system can help you find the “sweet spot.” With the increasing demands placed on today’s coal-fired power plants worldwide, operators are continuously looking for the best […]

Tagged in: