Features

-

Smart Grid

Combined Heat and Power Across the U.S.

The University of California, San Diego (see “Smart Power Generation at UCSD”) is just one of many combined heat and power (CHP), or cogeneration, systems in the U.S. A 2008 report by Oak Ridge National Laboratory (ORNL), “Combined Heat and Power: Effective Energy Solutions for a Sustainable Future,” notes that Texas has the most CHP capacity—much of it used by the petrochemical and petroleum refining industries. California ranks second, largely a result of “industrial demands, stringent air quality requirements, and effective policies that encourage adoption of CHP.”

-

Nuclear

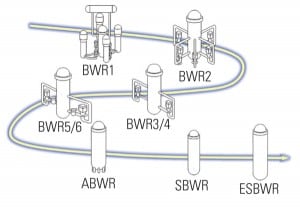

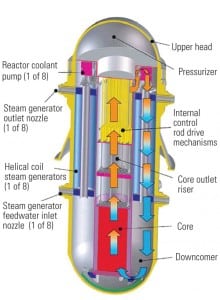

The Evolution of the ESBWR

The commercial nuclear industry is in the midst of developing multiple reactor technology options. Next in our series of articles exploring competing reactor technologies are GE Hitachi Nuclear Energy’s Advanced Boiling Water Reactor (ABWR) and Economic Simplified Boiling Water Reactor (ESBWR). The design improvements incorporated into these reactors include passive safety systems, design and construction simplification, and component standardization to reduce construction and operating costs.

-

Gas

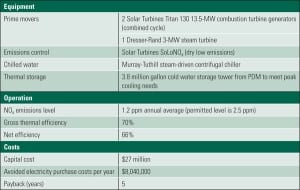

Smart Power Generation at UCSD

The University of California, San Diego has been accumulating awards for its savvy use of a constellation of power generation and energy-saving technologies. The campus already controls a fully functioning microgrid—including a cogeneration plant—and, as befits a research institution, is constantly looking for new ways to make its energy system smarter. This “living laboratory,” as campus leaders like to call it, demonstrates what it takes to build a smarter grid and why the effort is worth it.

-

Gas

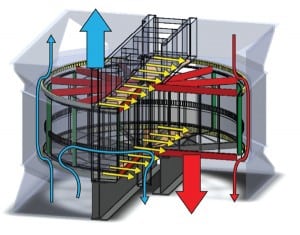

Microturbine Technology Matures

Microturbine technology has evolved from early systems of 30 kW to 70 kW to today’s systems, which can have individual ratings of 200 kW to 250 kW. Packages up to 1 MW are now available that can be assembled into multipac units for projects of 5 MW to 10 MW. These modern units are packaged with integrated digital protection, synchronization, and controls; they produce high combined heat and power efficiencies; and they are capable of using multiple fuels.

-

Nuclear

Are Smaller Reactors Better?

Is a paradigm shift—an economic and engineering earthquake—in nuclear power plant design on the horizon? For most of the past 50 years, the mantra in planning new nuclear plants has been “bigger is better.” But a growing number of nuclear power engineers and designers are contemplating a world where small is beautiful.

-

Nuclear

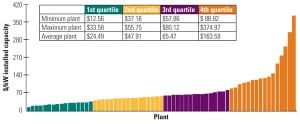

Benchmarking Nuclear Plant Capital Requirements

The EUCG Nuclear Committee’s primary goal is to optimize the costs and reliability performance of participating plants by publishing for its members a comprehensive database of performance metrics and best practices derived through surveys of its membership. Earlier reports examined staffing and performance data. In this exclusive EUCG report, we examine nuclear plant capital requirements.

-

Coal

Map of Coal-Fired Generation in the United States

Courtesy: Platts Data source: POWERmap All rights reserved. No reproduction allowed.

-

O&M

Air Preheater Seal Upgrades Renew Plant Efficiency

The air preheater is a critical, yet often overlooked, component of the boiler combustion air system. Evaluating and optimizing a heater’s performance is difficult given how entwined it is with the entire combustion system and the lack of standardized calculation tools. Reducing leakage by using modern seal technology will improve combustion efficiency, maintain fan performance, and keep your downstream air quality control equipment operating within spec.

-

O&M

Taming Condenser Tube Leaks, Part II

In Part I of this two-part report we examined the various chemical forces at work in condenser tube leaks, the steam plant components placed at risk, and the suite of instrumentation most capable of providing early warning of a leak. Assuming you were able to repair the leak and quickly resume operation, the next step is to identify the damage mechanisms that caused the problem so you can minimize future leaks.

-

O&M

FBC Control Strategies for Burning Biomass

As a boiler fuel, biomass has shown great promise while suffering from a slow development history. One factor limiting its use has been the combustion system. For the most part, conventional grate-fired boilers have been the only option. Today, the most efficient approach to burning biomass to produce electricity and steam is fluidized bed combustion (FBC). Whether you choose FBC or grate, biomass presents unique challenges to control system designers.