Features

-

Gas

RAM Process Optimizes IGCC Design

New methods of reliability, availability, and maintainability (RAM) evaluation help facilitate more-accurate plant output and revenue predictions, identify strengths and weaknesses of possible plant configurations, and determine potential improvements and enhancements for integrated gasification combined cycle plants.

-

Business

Who Needs an Owner’s Engineer?

In the past, members of a utility’s engineering staff spent their career designing and building new power plants. Today, many utility engineers find that opportunity comes around only once in a career. To fill the experience gap, an “owner’s engineer” company can add to a utility’s team a cadre of highly qualified power engineers who focus on avoiding design errors and keeping the project on schedule.

-

Coal

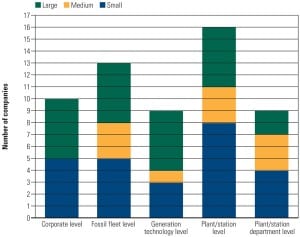

Benchmarking Fossil Plant Performance Measures, Part I: Station-Level Metrics

How does your company prepare and share fossil plant performance data? What data are important, and how much effort is required to collect and report the data? What are the most important statistics for reporting key fossil plant operations? The latest EUCG benchmarking survey reveals the favored fossil performance metrics at several of the largest utilities in eight key categories.

-

O&M

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

Nuclear

I&C Update on Plant Vogtle Units 3 and 4

Development of Vogtle Electric Generating Station Units 3 and 4—the first new nuclear power plant units in the U.S. in decades—has generated considerable excitement. The next generation of nuclear plants, represented by these units, includes at least two major improvements: the use of passive safety systems and a reliance on digital control systems. The latter represents a gigantic leap in modernization and a fundamental change in control of the plant.

-

O&M

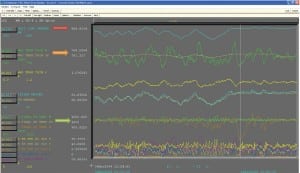

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

Gas

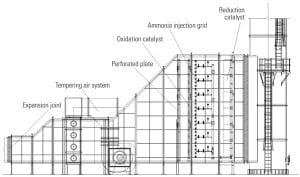

Automated Exhaust Temperature Control for Simple-Cycle Power Plants

A common concern for gas turbine power plants is treating exhaust gases to comply with laws restricting pollutants present in the gases that are emitted into the ambient atmosphere. The challenge for designers is to control the exhaust gas operating temperature within a range that maximizes performance of the oxidation and reduction catalysts.

-

Instrumentation & Controls

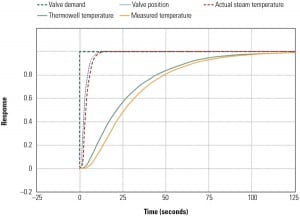

Thermocouple Response Time Study for Steam Temperature Control

One important factor in power plant control system performance is the response time of the process measurement used in the control system. The response time of boiler steam temperature sensors and thermowells is examined, as is those sensors’ and thermowells’ effect on desuperheater temperature response time and, therefore, steam temperature control performance.

-

Instrumentation & Controls

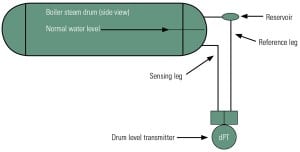

Concerns About Temperature-Equalizing Columns Used for Steam Drum Level Measurement

In the 1950s, temperature-equalizing columns were commonly used in steam drum differential pressure–based devices for measuring water level. However, these columns are problematic because a portion of the reference leg can flash to steam on a pressure decrease (load increase), and this will result in a temporary, false, high-level measurement, which adds to the swell effect. The columns can also result in measurement inaccuracies. It’s time to replace these antiquated instruments with a more modern reference leg.

-

Coal

Designing Fuel Systems for Large Biomass Plants

Compared with other solid fuel–fired plants, the systems and components required for handling and processing biomass appear quite familiar, but important fuel differences must be considered. A successful biomass plant design must provide flexibility for handling the expected wide range of biomass fuel properties and characteristics.