Features

-

O&M

Dominion’s North Anna Station Sets New Standard for Earthquake Response

On August 23, 2011, at 1:51 p.m., a magnitude 5.8 earthquake knocked both units at Dominion’s North Anna Power Station off-line—the first time such an event has occurred in the U.S. After 80 days of extensive evaluation and inspection by plant staff and representatives from the U.S. Nuclear Regulatory Commission, both units were back online. What occurred during those days is a remarkable story.

-

Nuclear

What Worldwide Nuclear Growth Slowdown?

Data detailing plans for new nuclear reactors worldwide show few effects of the March 2011 Fukushima accident. China and Russia in particular continue to be hot spots for nuclear development, but cost overruns, construction glitches, and ongoing safety reviews are slowing construction projects elsewhere.

-

Nuclear

Post-Fukushima Nuclear Power Development in China

China regards nuclear energy as a critical part of its strategic goal of achieving sustainable economic development while reducing environmental pollution. An analysis by North China Electric Power University predicts that the pace of nuclear power development may slow for a short time as a result of the Fukushima accident, but nuclear power is still a top development priority.

-

Coal

Potential Impacts of Closed-Cycle Cooling Retrofits at U.S. Power Plants

The Clean Water Act Section 316(b) rule changes regarding cooling water intake structures that are expected next year could affect up to 428 power plants, representing 1,156 individual units, according to the Electric Power Research Institute. Depending on plant size and the complexity of the retrofit project, retrofit capital costs could range from very low to over $500 million for large nuclear plants. The power industry total cost is projected to be over $100 billion.

-

Environmental

Hazy Timetable for EPA’s Proposed Tighter PM2.5 Standards

On June 15, in response to a court order, the U.S. Environmental Protection Agency (EPA) proposed new lower limits on particulate matter (PM) emissions that are scheduled for release in mid-December, although that deadline may be missed. Even with implementation delays, now is a good time to start paying closer attention to the requirements of the proposed standard.

-

O&M

The Evolution of Steam Attemperation

The fundamental design principles and process for modern steam desuperheating, or the attemperation of superheated steam in the power generation industry, have been evolving since the early 1930s. Meeting the requirement for steam quantity, quality, and temperature consistency is the foundation of traditional attemperator component design, particularly for fast-response combined cycle plants.

-

O&M

Reducing Ash Agglomeration in JEA’s CFB Boilers

A chronic operational problem with circulating fluidized bed boilers is ash buildup or agglomeration that turns into slag, which forces frequent shutdowns for cleaning. Solving the problem is tricky, because combustion efficiency relies on good fuel quality, but the best fuel for efficiency may not be the best fuel for minimizing furnace and tube fouling and ash plugging.

-

Coal

Are Economics Trumping Regulation?

The fate of coal-fired generation remains fluid as owners weigh environmental rules, the effect of low natural gas prices, and the shifting cost of investing in emissions control technology. An analysis of generating unit data suggests that smaller, older, less-efficient, and less-frequently dispatched assets are most vulnerable to retirements. Recently accelerated retirement dates for some units indicate that economic factors are a more important determining factor than pending environmental mandates

-

Coal

China’s Power Generators Face Many Business Barriers

China’s five largest power generators own half of that country’s power generating assets. Faulty policies and the rapidly changing global economy have made it difficult for these companies to fulfill the high expectations arising from enactment of the Power System Reform Scheme of 2002

-

Coal

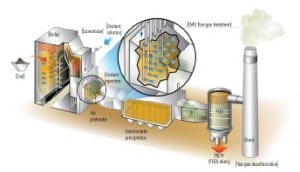

EMO Technology Promises Improved Mercury Removal

The latest Environmental Protection Agency mercury control limits in the Mercury and Air Toxics Standards present a significant technical challenge to the power industry. Shaw offers a cost-effective process that promotes mercury oxidation and removal in fossil fuel combustion applications that can potentially achieve consistent mercury oxidation above 95%. Shaw’s E&I Group EMO technology provides the industry with an alternative to halogen salt addition and activated carbon injection that can also be used to augment the performance of existing Hg control applications and strategies