COAL POWER Direct

-

Coal

The Coal Pile

This month’s photo was submitted by David Carter, power generation supervisor at Springerville Generating Station. Readers of POWER may recall that Springerville Unit 3 — the first pulverized coal – fired unit built in the U.S. in more than a decade — was that magazine’s 2006 Plant of the Year. Located in northeastern Arizona, the […]

-

O&M

The Coal Patrol: Looking Back at 2006

To borrow shamelessly from Charles Dickens, one of my favorite authors, for coal in 2006, "It was the best of times, it was the worst of times." No Escape The year began in horror. On January 2, most likely a result of a severe lightning strike, methane gas in the International Coal Group’s Sago Mine […]

-

Coal

PRB Tech Notes: Give Coal Handling the Priority It Deserves

Over the past 17 years — dating back to the 1990 Clean Air Act Amendments and including the introduction of retail competition — coal-fired power plants have become much cleaner and more efficient. Utilities have spent many billions of dollars to install pollution controls for regulatory reasons, and only slightly less to upgrade turbine-generators and […]

-

O&M

Coal Plant O&M: Elemental Analyzer Checks Quality of Delivered Coal in Real Time

When you receive a shipment, you don’t wait weeks to see whether you got what you paid for — do you? J.M. Stuart Generating Station doesn’t, but it used to. Since coming on-line in the early 1970s, the big plant, on the Ohio River near Aberdeen, Ohio, mechanically sampled coal shipments as they reached the […]

-

Coal

Coal Plant O&M: Coal Drying Reduces Pulverizer Start-up Costs

If coal leaving a pulverizer isn’t dry, it may plug up the coal pipes leading to the boiler. The coal-drying process in a pulverizer is similar to that used by flash dryers. Certain coals should be preheated to make them more combustible. Generally, preheating is done on higher rank coals — those with a low […]

-

O&M

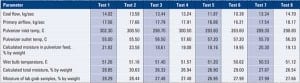

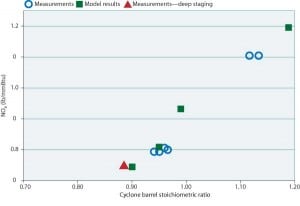

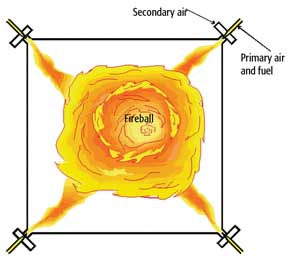

Emissions Control: Layered NOx Reduction on a 500-MW Cyclone-Fired Boiler

Historically, cyclone-fired boilers have been characterized as big emitters of NOx due to the very high temperatures in their primary combustion zone. Uncontrolled levels from 0.8 to 1.9 lb/mmBtu have been typical. The design of cyclone-fired units makes them impossible to retrofit with standard low-NOx burners. Prior to 1997, the conventional wisdom was that cyclone […]

-

O&M

Emissions Control: Cost-Effective Layered Technology for Ultra-Low NOx Control

Layering NOx control technologies can reduce a coal-fired unit’s NOx emissions to levels achievable by selective catalytic reduction alone. Advanced Combustion Technology Inc. (ACT) (www.advancedcombustion.net) has demonstrated that using several in combination can cut emissions from boilers firing eastern bituminous coal or No. 6 oil to less than 0.15 lb/mmBtu. The following two case studies […]

-

Coal

Emissions Control: User-Designed Large-Particle Ash Screens Minimize SCR Fouling

Large-particle ash (LPA), also called popcorn ash (Figure 1), is a serious concern for many coal-fired utility boiler operators who have retrofitted their unit(s) with a high-dust selective catalytic reduction (SCR) system. LPA formed in the boiler can easily carry over into the SCR reactor (Figure 2), where it often causes catalyst erosion damage and […]

-

Coal

The Coal Pile

The February 1907 issue of POWER magazine reported on the construction of a new coal-fired steam engine plant on the Merrimac River outside of Lawrence, Mass. According to the plant’s owner, "the simplest and most flexible means for handling coal… to the furnace is by animal muscle… that brings the coal to the firing floor […]

-

Coal

Speaking of Coal Power: Shedding More Heat Than Light

When Charles Dickens began A Tale of Two Cities with, "It was the best of times, it was the worst of times," he was referring to the French Revolution of the late 18th century. But Dickens’ words apply equally well to the American generation industry of the late 20th century. A decade of overbuilding U.S. […]