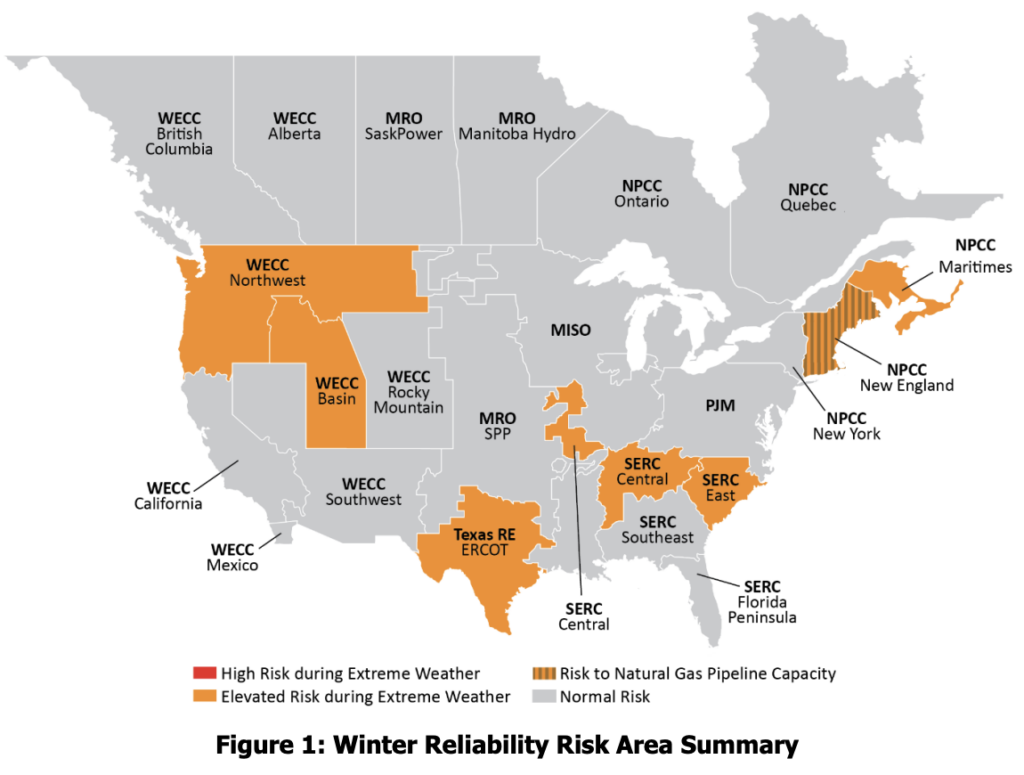

The stakes have never been higher for power generation facilities when it comes to extreme cold weather. Severe winter events exposed critical vulnerabilities across the U.S. power grid, leading to widespread outages and cascading failures. These events underscored a harsh reality: cold weather preparation is no longer an option; it’s a necessity.

To meet this challenge head-on, the North American Electric Reliability Corp. (NERC) has introduced the EOP-012 regulatory standard, mandating that generation facilities implement specific, robust measures to ensure reliability in the face of extreme temperatures. For utility compliance managers and engineers, adherence to these regulations is not just a requirement, but also a critical safeguard to protect communities, operational integrity, and the bulk electric system (BES, also known as the grid). Preparing your facility now is essential to avoid disruptions, steep penalties, and the devastating consequences of a system failure during the next cold snap.

The Need for NERC EOP-012

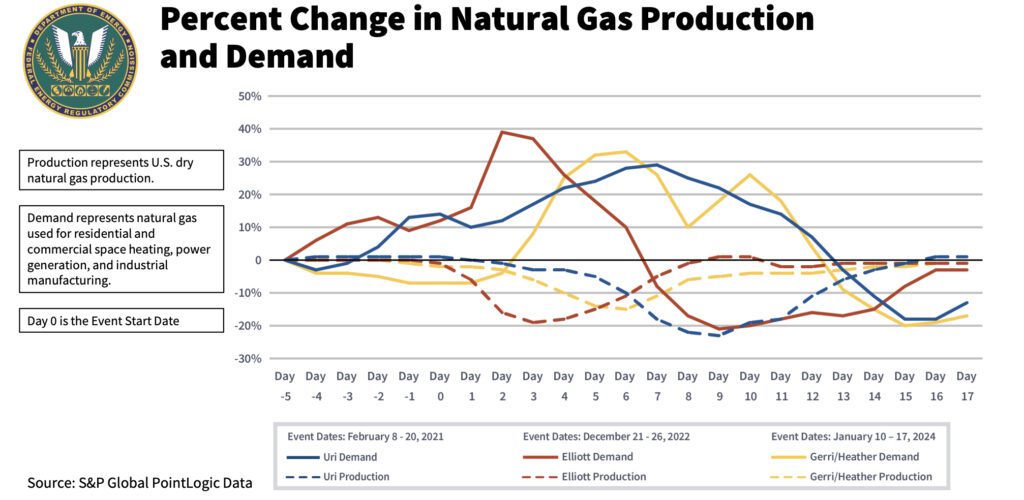

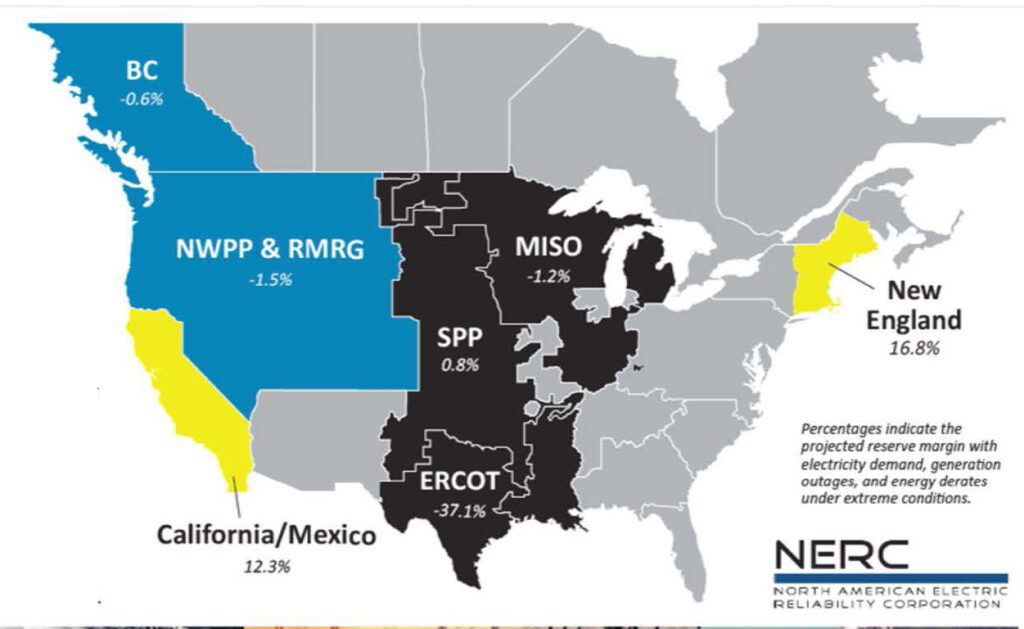

Severe cold weather events in the U.S. in recent years, such as the Midwest Arctic Polar Vortex of 2019, Winter Storm Uri in 2021, and Winter Storm Elliot in 2022, have placed unprecedented strain on the North American power grid. During such events, vulnerabilities such as equipment freezing and generation outages have resulted in widespread power failures. By introducing EOP-012, NERC aims to preserve grid reliability by mandating cold weather preparedness at power generation facilities.

Key Components of NERC EOP-012

NERC EOP-012 compliance requires generator owners (GOs) and generator operators (GOPs) to establish, implement, and maintain comprehensive cold weather preparedness plans. Below are its key requirements broken down into actionable components.

Cold Weather Preparedness Plan (Requirement R1). Facilities are required to identify and document preventive measures to ensure operational reliability during extreme cold weather conditions. This includes:

- Extreme Cold Weather Temperature (ECWT). GOs must calculate the ECWT for their facility based on the criteria imposed by NERC. This provides a site-specific benchmark for cold weather preparedness.

- Freeze Protection Measures. Protective measures such as heat tracing, insulation, or permanent enclosures must be implemented for critical equipment.

Differentiation by Facility Age (Requirement R2). Facilities entering operation after Oct. 1, 2027, are subjected to more stringent requirements compared to pre-existing sites, given that newer facilities can integrate compliance measures into their design.

Proving Compliance During Audits. Even facilities operating reliably in cold weather must prove compliance by maintaining documentation, training records, and evidence of corrective actions.

Challenges to NERC EOP-012 implementation

Many GOs and GOPs, particularly those in regions unaccustomed to extreme cold weather, face significant hurdles in achieving compliance. These challenges include equipment limitations, budget constraints, and gaps in audit readiness.

Facilities in colder regions typically have existing freeze protection measures to ensure operational reliability. However, the challenge lies in documenting compliance for audits. Many operators may be meeting operational needs but lack the necessary evidence to demonstrate compliance during a NERC audit.

Generators located in traditionally warmer climates face unique challenges as they often operate with minimal cold weather measures in place. Budget constraints commonly exacerbate the situation, as the cost of implementing freeze protection measures may exceed existing resources. Facilities in warmer regions often require tailored solutions, such as the implementation of temporary enclosures or forecasting-based action plans, to address sporadic cold weather events efficiently.

Practical Steps to Achieve Compliance

To ensure both operational reliability and regulatory compliance with NERC EOP-012, facilities can adopt the following strategies.

Conduct a Cold Weather Assessment. An initial engineering analysis (as outlined in Requirement 1.2.2.) of vulnerabilities at your facility will identify gaps in both operational and regulatory compliance. Prioritize critical areas such as freeze protection for critical equipment, validate ECWT calculations, and provide recommendations for cold weather robustness.

Invest in Audit Readiness. However, being operationally robust is not enough to pass audits. All compliance measures must be well-documented. This includes maintaining detailed cold weather preparedness plans, training records, ECWT calculations, and evidence of implemented freeze protection measures.

Tailor Solutions to Site-Specific Needs. Facilities in areas with infrequent cold weather may require innovative, cost-effective solutions such as deployable heating units, weather forecasting logs, and event-triggered corrective actions. These measures should align with NERC guidelines while accounting for budget and climate differences.

Implement Preventive Measures for High Winds. Facilities in areas with significant wind exposure during low temperatures must enhance enclosure designs and freeze protection systems to account for wind chill effects. Temporary plastic enclosures may suffice in warmer climates but will require sturdy alternatives for colder, windier regions.

Provide Comprehensive Training for Personnel (Requirement R5). Develop and deliver a thorough training program for all plant personnel responsible for implementing your cold weather preparedness plan. The program should cover the standard’s requirements, site-specific freeze protection measures, special operating protocols, and how to respond effectively during an event.

Hire External Experts for Compliance Support. If in-house expertise is limited, hiring specialized consultants to bridge the gap between operational needs and NERC compliance requirements can be invaluable. Consultants with experience in NERC standards can provide customized cold weather solutions, audit preparation, and practical engineering analysis.

Case Study: Balancing Compliance and Operational Needs

One power generation company with facilities in Florida and Illinois illustrates the disparity in cold weather approaches. While the Illinois facility had a robust cold weather readiness plan with no budget constraints, the Florida facility operated with limited resources. To meet compliance without significant capital investment, a weather forecasting log and action plan were implemented. This plan outlined tiered measures activated based on forecasted temperature thresholds (35F, 32F, etc.). Though temporary, these measures effectively met NERC EOP-012 standards at a fraction of the cost of permanent installations.

Building Resilience: Turning Compliance into Operational Strength

Cold weather preparedness, and proving it is in place, is no longer optional for power generation facilities. With NERC EOP-012 setting clear guidelines, achieving compliance is essential to ensure reliability during extreme weather events. By taking proactive steps now, facilities can strengthen operations, address vulnerabilities, and be well-positioned to meet the requirements of this regulatory standard and avoid potential fines.

Start by evaluating your facility’s readiness, tailoring solutions to your specific needs, and maintaining thorough documentation for audits. Whether in colder or traditionally warmer climates, every facility can benefit from a robust cold weather strategy that prioritizes operational reliability and community protection.

Preparation is not just about avoiding penalties; it is about building resilience and ensuring your facility is equipped to handle future challenges. By getting ahead of these requirements today, you are investing in the stability of your operations, the safety of your teams, and the trust of the communities you serve.

—Rachael Williams is senior technical lead, NERC Compliance, with ENTRUST Solutions Group USA.