Latest

-

News

NERC: Efforts to mitigate climate change could strain North American grids

Widespread efforts aimed at reducing carbon emissions and increasing the use of renewables for the generation of electricity will fundamentally determine the future course of electric reliability across North America, the North American Electric Reliability Corp. (NERC) said in a recently released report. “We are concerned that, when viewed from a continent-wide perspective, current climate […]

-

O&M

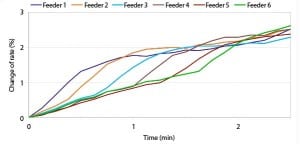

Innovative Control Strategies Improve Boiler Dynamic Response

The more capable a power-generating unit is of reacting quickly to changes in load demand, the more profitably the unit can be operated. An improvement in load dynamics means that additional control response and capacity can be made available to the power grid. These characteristics are especially in demand in regions where a fast-responding unit can supply energy as ancillary services at a premium price.

-

Commentary

The GAO Comes Clean on CCS

The Government Accountability Office (GAO), the investigative arm of the U.S. Congress, just released its report on the status of carbon capture and sequestration (CCS) technology and its view of the technology’s future development challenges. In general, the GAO concludes that the technology faces grave technological, regulatory, economic, and legal barriers that will not be […]

-

Coal

Low-NOx Retrofit for Firing Coal/Petroleum Coke Blends

Replacing existing, older-generation controlled-flow split-flame burners on Unit 1 at the Seminole Generating Station with Foster Wheeler’s new low-NOx burners and overfire air additions reduced NOx emissions. This case study provides all the details and post-installation test results.

-

Coal

Up in Smoke: Measuring Mercury in Stack Gases

Two types of mercury monitoring are required of coal-fired power plants: continuous emission monitoring and periodic Relative Accuracy Test Audit. One of the more attractive approaches for these analyses is provided by the Hydra-C Appendix K from Teledyne Leeman Labs.

-

Coal

California Climate Plan Touts New Renewables, Trading Allowance Schemes

In a sweeping climate change proposal that could serve as a model for the nation, two California agencies have proposed a comprehensive program for reducing the state’s greenhouse gas emissions that calls for aggressive improvements in energy efficiency, higher targets for renewable energy, and an innovative scheme for allocating emission allowances to electric utilities.

-

Coal

GAO: Lack of U.S. Greenhouse Strategy Slowing Carbon Capture

A Government Accountability Office (GAO) study released in late September concludes that technological, legal, and regulatory uncertainties—compounded by the absence of a national strategy for combating global warming—are blocking deployment of crucial technology to capture and sequester carbon dioxide from coal-fired power plants.

-

Coal

“Cap and Dividend” Proposal Targets Carbon Suppliers

As senior members of Congress lay the groundwork for a new legislative debate on climate change next year, a new proposal making the rounds of Capitol Hill offices would replace the cap-and-trade approach now in vogue with one in which all carbon permits are auctioned and all auction revenues are returned to consumers.

-

Commentary

Building a Firm Foundation for GHG Regulation

Roger Feldman

Proposed U.S. legislation appears likely to use carbon offsets or credits, although the details remain unclear. I wonder if these schemes adequately support the goal of global greenhouse gas emission reductions. -

Commentary

Out of Sight, Out of Mind

Dr. Robert Peltier, PE

The Government Accountability Office (GAO), the investigative arm of the U.S. Congress, just released its report on the status of carbon capture and sequestration (CCS) technology and its view of the technology’s future development challenges. In general, the GAO concludes that the technology faces grave technological, regulatory, economic, and legal barriers that will not be easily overcome.