Ofgem, the UK’s energy markets regulator, has deemed Highview Power’s proposed 3.2-GWh liquid air energy storage facilities at Hunterston and Killingholme eligible under its cap-and-floor regime, advancing them toward a final decision in Q2 2026. Alongside the 300-MWh Carrington project under development near Manchester, Highview’s portfolio is poised to provide more than 7 GWh of dispatchable energy, the company said.

The development is pivotal for the UK power sector, given that it could bolster system flexibility and energy security at scale. By 2030, renewable capacity is expected to reach 128 GW against a 62 GW peak demand, yet the lack of long-duration storage remains a critical barrier to a zero-carbon grid. Highview’s LAES projects, supported by the cap-and-floor regime, could help close the 58-GWh non-battery storage gap identified by the National Electricity System Operator (NESO)—the body responsible for analyzing system needs—and support the Clean Power 2030 plan, the UK’s flagship energy strategy to decarbonize electricity by the end of the decade.

Ofgem confirmed 77 applications—including Highview’s Hunterston (Scotland) and Killingholme (Lincolnshire) 3.2 GWh plants—have passed its eligibility screening and entered the second phase of the cap-and-floor “super battery” support scheme. The government-driven initiative, launched in April 2025, underwrites revenue risk for long-duration electricity storage (LDES) projects via a guaranteed minimum “floor” and a consumer-protecting “cap” on excess returns. Over the next nine months, Ofgem and NESO will conduct a final project assessment, which entails evaluating customer benefits—such as avoided curtailment costs, capacity value, and ancillary services—before issuing cap-and-floor awards in summer 2026.

“Renewable power is the key to seizing control of our own energy system and end the costly reliance on the turbulent wholesale gas market, so we don’t want to see a single watt go to waste,” said Beatrice Filkin, director of major projects infrastructure for Ofgem.

Filkin added that boosting Britain’s ability to store homegrown energy would let turbines keep turning at peak output, while reserves of excess clean power could be drawn on during lulls. She noted Ofgem is considering a diversity of approaches—including batteries, compressed air, and pumped hydro—through the cap-and-floor process to ensure a resilient and good value-for-money power system. Energy Minister Michael Shanks called the scheme “another huge step forward in reversing the legacy that has seen no new long-duration storage built for 40 years,” underscoring its role in securing Britain’s energy supply and protecting consumers.

Highview Power’s LAES system operates through three core stages: electricity-driven air liquefaction, cryogenic storage and power recovery. In the charging phase, ambient air is cleaned, cooled to –196 °C and liquefied—a process in which 700 litres of air condense into 1 litre of liquid. The cryogen is stored at low pressure in insulated tanks before regasification—augmented by captured waste heat or industrial cold—to expand through turbines and generate power. The thermodynamic cycle delivers multi-week energy retention, modular siting and mature supply-chain components for gigawatt-scale, long-duration storage, the company says.

Highview Power combines technology development, project engineering, and asset ownership across the full LAES value chain. Since its 2011 pilot at SSE’s biomass site, Highview has delivered a 5 MW pre-commercial demonstrator at Viridor’s Pilsworth landfill and is building the 300 MWh Carrington plant. Securing cap-and-floor eligibility for two 3.2 GWh projects at Hunterston and Killingholme marks more significant leverage for the company. The company’s business is rooted in its in-house cryogenic design, modular tank fabrication, and proprietary heat-recovery integration, which underpin both its EPC services and its growing pipeline of owned and third-party LDES assets.

The UK’s cap-and-floor regime, first introduced in 2014 to support cross-border electricity interconnectors, has unlocked more than 8 GW of new capacity by offering investors stable, predictable returns. The model is now being applied to long-duration electricity storage, providing a revenue “floor” to underwrite developers against low wholesale prices and a “cap” to prevent windfall gains and shield consumers. Clean Power 2030 mandates 58 GWh of non-battery storage (£20 billion investment) and 34 GWh of batteries (£8.5 billion) by 2030 to maintain security during the transition to a zero-carbon grid.

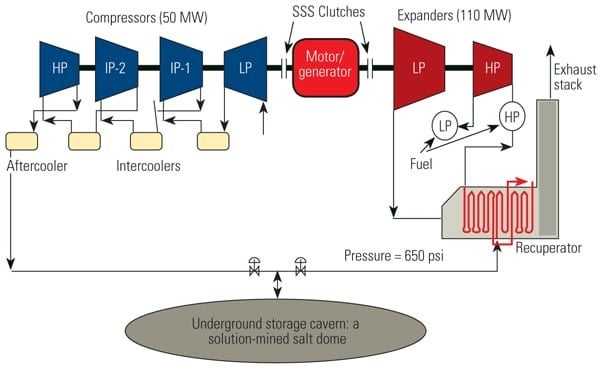

“Great Britain currently has 2.8 GW of LDES across four Pumped Storage Hydro (PSH) facilities in Scotland and Wales,” Ofgem noted. “These operate like natural batteries, with electricity stored by pumping water up a mountain to be released when required and are already crucial to the electricity system. Other forms of LDES—such as liquid air energy storage (LAES), compressed air energy storage (CAES), Li-Lon and flow batteries—are also being developed.

Highview’s two projects are part of a broader £2 billion investment plan to deploy 6.4 GWh of LAES by 2030, leveraging sovereign-backed revenue certainty to attract pension and sovereign-fund capital.

Ofgem’s final cap-and-floor awards are expected summer 2026 and could define the construction roadmap for Hunterston and Killingholme. Meanwhile, Highview’s 300 MWh Carrington LAES plant will commission in 2026, potentially setting the stage for the full 6.4 GWh build-out by 2030.

—POWER staff