Localized intelligence will reshape energy operations, enabling edge-based generative artificial intelligence (AI) models to deliver precision, agility, and control at every layer of power operations.

For decades, power generation companies have relied on powerful machine learning (ML) tools to drive the precise operations necessary to supply the world’s nearly limitless appetite for electrical energy. Deep benches of highly experienced engineers, technicians, and operators would regularly implement, adjust, and monitor ML tools to provide a wide array of critical operations enablers: increased reliability, optimally tuned closed-loop process control, alarming and alerting, scheduling, and more.

Today, as demand for energy has dramatically increased, so too has the need for powerful tools to help drive operational excellence. However, the deep bench of personnel needed to implement and maintain those technologies has not scaled in parallel. In fact, skilled workers are harder to find than ever, and power companies are feeling the strain.

Fortunately, another technology has evolved in parallel to help close the experience gap and drive more efficient, effective, secure, and reliable operations in the power industry. Artificial intelligence (AI) is the next evolution of assistive technology, built on a foundation of ML, to help organizations accomplish rapid, productive change in their operations and maintenance. Today, AI is impossible to miss. It is in the headlines, mobile devices, the art studio, and enterprise business systems. However, one place AI technologies are struggling to take hold is in the control room—or, more precisely, the control layer.

The reticence to integrate AI into control is understandable. Modern AI—particularly, generative AI (GenAI)—is still a work in progress, and companies are wise to be thoughtful when implementing unproven technology in their control environments. Process control requires safe, stable, reliable operation 24/7 to reduce the risk of safety incidents and costly production loss. Moreover, much of a company’s most critical intellectual property resides in the control layer, so organizations are typically cautious with its exposure.

However, there can be little doubt that one day GenAI will impact process control, even if nobody can say how just yet. That delay, however, does not mean understanding and pursuing strategies around the implementation of AI is useless. Quite the contrary, when GenAI intersects with control, the step change in operations is likely to have a significant impact, and those ready for it will be able to capitalize on game-changing competitive advantage for their organizations.

Considering some of the potential paths for the future of GenAI in control, as well as the ways it might be implemented, has real value, if only to help companies take the small steps necessary today to prepare a less complex and cumbersome path for achieving massive gains tomorrow.

How Is GenAI Different?

Though the world has been hearing about AI for years, many people do not yet fully comprehend that GenAI is something new. GenAI presents, at the very least, an appearance of the ability to reason, allowing it to make inferences between data points without needing large amounts of custom software. Ultimately, this capability manifests as the ability to generate original content—which in turn feeds the original engine, expanding and strengthening it.

Most people have seen at least a small example of how this works. Asking a GenAI chatbot a question, either via a web interface or an enterprise business system, will nearly always result in some answer, whether it is about tree frogs or thermocouples. Those results are a step change in AI capability for two key reasons.

First, the user can ask a question of the GenAI in natural language, making it much easier to be specific and to continually refine the logic of the query. Second, it is tremendously efficient because nobody needed to manually code the ability to ask that specific question and provide an answer. Using its large language model (LLM), the AI can parse, analyze, research, evaluate, and respond in natural language—or, where desired, in a variety of natural languages—in seconds.

Where the reasoning capability truly gains power, however, is in the capability to programmatically prompt AI models to empower direct interaction with applications. Today’s programmers are already using these prompts, along with the appropriate application programming interfaces (APIs), to drive new capabilities with dynamic AI-driven data enrichment and content generation (Figure 1).

|

|

1. As new energy sources capture an increasing market share, powerful artificial intelligence (AI) tools will be needed to help drive the smart grids of the future. Courtesy: Emerson |

Capability, with Caveats

While the potential of GenAI in industrial control systems is immense, it is important to acknowledge that the technology is still in its early stages and evolving rapidly. One significant challenge is AI’s tendency to generate “hallucinations”—outputs that may appear plausible but are factually incorrect or lack grounding in the data. Additionally, the transparency of how generative AI arrives at its conclusions and recommendations is often limited, making it difficult for operators to fully trust or validate its outputs. These issues highlight the need for robust validation mechanisms, human oversight, and ongoing research to enhance the reliability and interpretability of generative AI in critical industrial applications.

The Challenges of GenAI in Power Operations

The potential of GenAI is tremendously exciting, but using it in power generation is not as simple as connecting a large, public GenAI model to the control system. In fact, that very sentence likely dramatically raises the blood pressure of any engineer or operator who reads it. One of the reasons for that trepidation is because large, public GenAI models must operate in the cloud to provide the necessary processing power and storage to manage their massive LLMs—and few operations teams have any willingness to connect their control systems to the cloud.

There are a couple core reasons for this hesitancy. First, the cloud, regardless of cybersecurity protocols, is a shared space. Connecting the control system and its operational data to a public space immediately puts an organization’s intellectual property at risk, along with its continuity of operation for critical systems. While unlikely on the most secure platforms, data breaches are possible on absolutely any shared platform, making the risk far too high for most operations teams to tolerate.

In addition, North American Electric Reliability Corporation (NERC) Critical Infrastructure Protection (CIP) regulations are strict and challenging to follow even on a local level. While it is likely possible to create a NERC CIP compliant connection to a public GenAI model, the complexity, risk, and limitations would make the process more cumbersome and costly than it is worth.

Moreover, accomplishing such data egress would likely require data diodes or other technology to move the data to a data lake where it could be consumed by the AI engines. Such a process would be far too slow to impact operations at the control level, and it would also result in no clear path for moving the data back to the control layer.

Ultimately, many organizations find themselves stuck. They want to take advantage of the benefits of GenAI to support and upskill their limited and inexperienced staff. They realize they need powerful AI models and GenAI support to drive advanced automation, but they cannot safely and efficiently take advantage of those tools in the technology layer where they would be most useful.

GenAI Benefits Bring Real Value

While implementing GenAI at the control layer appears to be an uphill battle, there are very good reasons automation solution providers are continuing to pursue it as an option. GenAI has the potential to deliver tremendous value to process applications if industry can find a way to make the solution work in a reliable and secure manner.

First and foremost, GenAI has the capacity to combine operational diagnostics more effectively and efficiently with advanced pattern recognition to help deliver better overall visibility of both asset and equipment health, along with process optimization. As more experts leave the industry, taking their decades of institutional knowledge with them, newer and greener operators and technicians will rely heavily on technology to help them continually achieve operational excellence. Not only does GenAI have the capacity to raise the bar on what operational excellence truly means, it also provides decision support and upskilling to help operators reach this goal faster.

Moreover, one of the key benefits of LLMs and the natural language capability inherent in GenAI is the capacity for operations assistants to help users perform at their best. AI models have the capacity to consume operations procedures, control strategies, and graphics, and act as trusted advisors, helping operators understand what is happening in the control system, and providing recommendations that users of nearly any skill level can evaluate and implement for better performance.

GenAI tools can even be used for automated health monitoring, cybersecurity and intrusion detection, and creating control sheets or graphics to save engineering time and effort. The capabilities are limitless and exciting, but they must be implemented first.

New Strategies May Help Navigate Complexity

So, if operators cannot connect their control systems to cloud hosted GenAI engines, how will they ever reap the benefits that could deliver a paradigm shift in operational efficiency? The key is thinking outside the box, or, perhaps, outside the cloud. While GenAI grew up on a single, large, open AI model, that is not the only option. As the technology advances, and if teams are willing to narrow the scope of their individual AI engines, they will likely be able to run many smaller models on local platforms right at the control layer. These types of GenAI models can capture qualitative behavior to augment controls. This capability will likely be most useful during abnormal conditions where there may be multiple failures that potentially cause the base control system to have difficulty maintaining control.

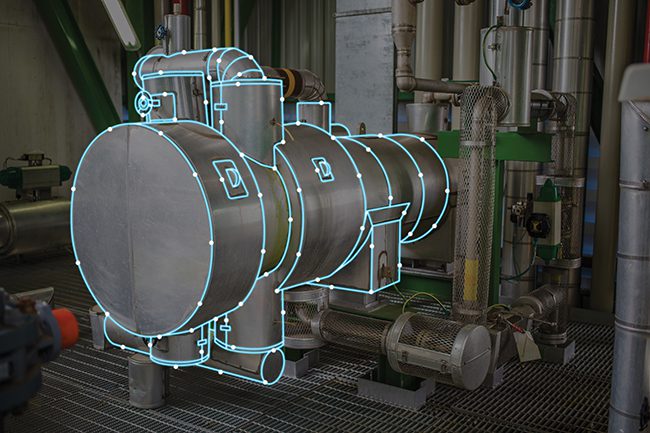

Already today, some of the pre-trained smaller GenAI models are very capable out of the box. These models are then fine-tuned for a specific control application by using either generic equipment information, or even specific asset information. For example, a small GenAI model may be trained on the basic concepts of how a gas turbine works, or it may be specifically trained to understand the specifications, thresholds, limitations, and core design of an individual model of gas turbine produced by one manufacturer.

In fact, it is highly likely that the power industry will see companies invest in general models that understand behavioral characteristics for particular applications—such as hydro, gas turbines, batteries, solar, wind, or even the control system itself—that are further tuned onsite with information unique to the control layer’s specific equipment and configurations (Figure 2).

|

|

2. Small, pre-trained generative AI models can be fine-tuned for specific control actions and assets. Courtesy: Emerson |

As these smaller models rise in popularity, teams will be empowered to deploy GenAI solutions that are more focused on their unique circumstances. This type of solution eliminates the risks of cloud technology and is more focused on the exact operations it is designed to perform.

As a result, it is simpler to manage and maintain, and easier to protect with AI guardrails. For example, the more limited the scope of the training, the less likely it will be that the AI will run out of answers and make things up that are irrelevant to the existing configuration. Moreover, these solutions will be easier to secure, using the same NERC CIP layers of protection the operations team already employs.

A Vision for a GenAI Future

AI is still very new, and there are too many unknowns to perfectly predict how operations teams will most effectively implement GenAI solutions to support their operators as power systems continue to increase in complexity. Technology—infrastructure in particular—will continue to change to support new options and new configurations for AI in the control room.

However, the small GenAI models supporting this evolution are just over the horizon, and those developed with automation solutions in mind will help today’s power providers get a foot in the door with a technology that will shape the future of energy generation and distribution.

—Rick Kephart is the vice president of technology for Emerson’s power and water solutions business.