Plant Design

-

Commentary

How U.S. Power Generators Are Preparing for 2014

The business environment for generating companies worldwide continues to become increasingly complex, and not just as a result of regulations. Even in the U.S., the concerns and constraints faced by generators

Tagged in: -

Gas

Korean Utility Plans First Underground Combined Cycle Power Plant

The oldest power plant in South Korea is making way for something so new that no one has even attempted it before. Korea Midland Power Corp. (KOMIPO) announced earlier this year that Seoul Thermal Power Station, built in the 1930s, would be replaced with a new 800-MW two-unit combined cycle power plant—one that will be built […]

Tagged in: -

Gas

Practical Considerations for Converting Boilers to Burn Gas

Many utilities have taken advantage of relatively low-cost natural gas to address environmental pressures and upgrade their power generation portfolio in one of three distinct ways—replace, repower, or

-

O&M

How Stealth Combustion Losses Lower Plant Efficiency. Part 1: The Problem

At the average coal-fired power plant, the battle to reduce net heat rate is complicated by skin-tight maintenance budgets, staff reductions, and—for some—the switch from baseload to mid-peaking service. The most fruitful approach to improving a plant’s heat rate is to optimize combustion in its boiler, particularly by minimizing the amount of “stealth” air in-leakage.

-

Coal

Leadership Changes at Mississippi Power as Kemper IGCC Cost Overruns Soar

Cost overruns of nearly $1 billion to build the 582-MW Kemper integrated gasification combined cycle (IGCC) plant in Kemper County, Miss., were underscored on May 20 as Mississippi Power’s Board of Directors took the dramatic step of replacing the Southern Co. subsidiary’s leadership.

-

O&M

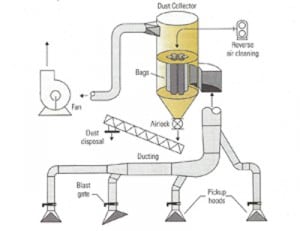

Give Your Plant a Dust Control Tune-Up

Every piece of equipment that transports or processes coal creates some level of particulate matter. Having a strategy for coal dust management in your plant is essential.

-

Coal

Kemper County IGCC Project Update

The integrated gasification combined cycle (IGCC) plant located in Kemper County, Mississippi, is a 2 x 1 plant that will produce 582 MW at peak and 524 MW fired on syngas, with ammonia, sulfuric acid, and carbon dioxide as by-products. The carbon dioxide will be used for enhanced oil recovery (EOR). Engineering was completed in Q3 2012, and the facility’s commercial operation date is planned for May 2014.

-

Coal

Project Planning Key to Smooth J.T. Deely 2 SCR Retrofit

Recent experience on the Deely 2 SCR retrofit project reminds us that the time spent in thoroughly planning a project prior to the start of construction is usually repaid with avoided construction delays.

-

O&M

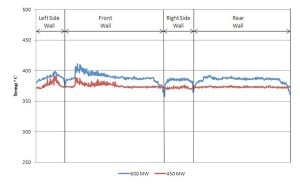

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 3

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in the Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 1 of this three-part article presented a summary of the project design features. Part 2 discussed the boiler technology. This third and final part reviews the plant’s performance test results.

-

Coal

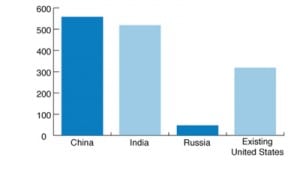

Countries Worldwide Propose to Build 1,200 New Coal Plants

While the war on coal is working to reduce coal generation and consumption and associated carbon dioxide emissions in the United States, many world economies are looking toward coal for future generation needs. China, India, Russia, and Germany, to name a few, are building coal-fired power plants.