Plant Design

-

Coal

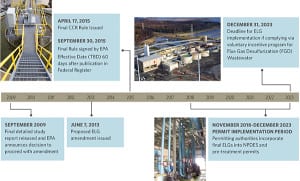

Take These Five Steps Now to Ensure ELG Compliance at Your Power Plant

The first effluent limitation guidelines update since 1982 is game-changing for many U.S. power plants.

-

Solar

The Future of Load Control for Solar PV

Solar power has taken off the training wheels. Once an afterthought, solar photovoltaic (PV) generation has been one of the major sources of new capacity for several years. According to statistics from the

-

Water

Water-Stressed Regions Provide Proving Grounds for Advanced ZLD Systems

In water-stressed regions outside the U.S., power producers and other industrial water users are incorporating higher levels of water reuse, some to the point of zero liquid discharge (ZLD), due to heightened

-

Hydro

Ethiopia Begins Generating Power from 1.87-GW Gibe III Hydro Plant

Ethiopia’s generation capacity got an immense boost as operations began at the 1.87-GW Gibe III hydroelectric power plant in the middle reach of the Omo River basin this October. The plant—Ethiopia’s

Tagged in: -

O&M

Smart Access Planning Enables Efficient Cooling Tower Maintenance

Two hyperbolic cooling towers rise 495 feet over Exelon Corp.’s Byron Generating Station about 110 miles west of Chicago, Ill. The towers help cool the two Westinghouse pressurized water reactors that are capable of generating up to 2,346 MW at the site. Like all classic wet transfer hyperbolic cooling towers (Figure 1), the Byron Generating […]

Tagged in: -

O&M

Ensuring Reliable Boiler Operation Through Proper Material Analysis

Creeped out and fatigued—that’s the state of many coal-fired boilers these days. Understanding failure mechanisms and suitable testing methods for identifying potential trouble can help you find problems before the problems find you. Even as the current regulatory environment pushes new power generation to utilize natural gas over other fuel sources, a significant amount of […]

Tagged in: -

Coal

SaskPower Admits to Problems at First “Full-Scale” Carbon Capture Project at Boundary Dam Plant

Once again, a first-of-a-kind technology at a coal-fired power plant that is designed to reduce its greenhouse gas footprint has run into design, operational, and cost problems. This time, it’s Saskatchewan, Canada utility SaskPower’s Boundary Dam Carbon Capture project that’s facing scrutiny. (Earlier this week, an overdue precombustion carbon capture project, Mississippi Power’s Kemper County […]

Tagged in: -

Renewables

Hydropower Innovations Make Some Noise

Hydropower is booming, but unless you live in China, Latin America, or Africa, you may have missed it. Global installed capacity of hydroelectric generation has grown by more than 25% over the past decade

-

Gas

GE Announces Digital Power Plant as Component of the Industrial Internet

Before the official start of its Minds + Machines event in San Francisco this week, GE announced the launch of its “Digital Power Plant” during a briefing for the trade press. A formal announcement was to follow in the afternoon. Dick Ayres, general manager of software solutions, power generation services, explained that the company’s Predix […]

-

O&M

Leveraging Fuel Flexibility for Coal Power Plant Survival

While having lunch at a downtown café with my friend the biology professor, the subject of animal extinction arose. “When it comes down to it, we really don’t know exactly why most prehistoric species