O&M

-

O&M

Plantwide data networks leverage digital technology to the max

To make the most of their digital devices and enable the sharing of data by different departments, new and old plants alike need a reliable digital data infrastructure.

-

O&M

Upgrade your BWR recirc pumps with adjustable-speed drives

The U.S. is home to more than 30 boiling water reactors of BWR-3 through -6 vintage. At one time or another, all have experienced obsolescence, reliability, or control problems with their reactor recirculation flow control systems and components. Temporary down-powers are often required for corrective maintenance. Exelon Nuclear plans to begin upgrading the recirculation pump motor drives at its BWRs in the spring of 2009. The upgrade project’s technical design and business case were developed in great detail before the project was approved. This article presents the results of all key internal analyses.

-

O&M

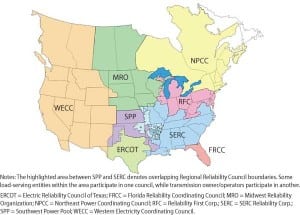

The Coal Patrol: Demand Growth — and Reliability — Are Still Supply-Limited

While noting marginal improvements since last year, America’s power reliability watchdog recently warned that the nation’s growing thirst for electricity will still far exceed planned increases in generation capacity over the next 10 years, and that reserve margins could dip below optimal levels within two or three years in California, the Rocky Mountain states, New […]

-

O&M

Tech Notes: Intelligent Sootblowing Needed to Keep Uprated Units Clean

The National Coal Council estimates that 40,000 MW of additional generating capacity is available to existing U.S. coal-fired plants simply by making efficiency improvements. Because decreases in production costs go straight to a plant’s bottom line, efficiency projects usually have short payback periods, especially if implemented in concert with mandatory environmental upgrades. One often-overlooked consequence […]

-

O&M

Focus on O&M (October 2007)

Why bypass desuperheaters fail; DSSP, CAD, and fast casting salvage nearly totaled pump; Seals of approval; Making gas turbine plants quieter

-

O&M

Focus on O&M (September 2007)

Replace pumps, cut repair bills / New bolts show their stress level / Up a certain creek, without a filter / Hang up those cables and hoses

-

O&M

The Coal Patrol: Mine Safety Deserves More Than Lip Service

Every step forward in underground U.S. mine safety in the 20th and 21st centuries has been on the backs of mangled and dead coal miners. That grisly observation is unassailable. Following the August tragedy at the Crandall Canyon mine in Utah that killed six miners and three would-be rescuers, the federal Mine Safety and Health […]

-

O&M

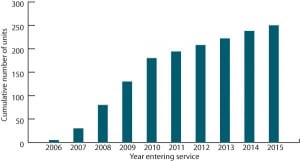

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]

-

O&M

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

O&M

Focus on O&M (August 2007)

Stop valves from leaking money / Integrating plant and equipment models / Pricing priceless knowledge