O&M

-

O&M

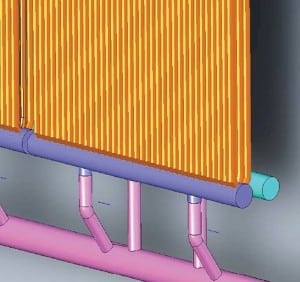

Ten Years of Experience with FAC in HRSGs

We first reported on combined-cycle plant reliability concerns due to erosive wear and flow accelerated corrosion (FAC) in heat-recovery steam generator (HRSG) pressure parts at the 1999 EPRI Maintenance Conference. More than 10 years later, these damage mechanisms remain significant contributors to forced outages, pressure part repairs, and major component replacement.

-

O&M

Taming Condenser Tube Leaks, Part I

Summer peaks are still with us, and every unit on your system must be prepared to operate at a moment’s notice. Spot power prices are so high that you expect phone calls asking for a few more megawatts from your units. Then your plant chemistry lab calls to report a condenser tube leak. Your options are few: Shut down immediately and get charged with a forced outage, ignore the leak and keeping running until fall, or schedule a maintenance outage next weekend and hope the leak can be found and fixed. In Part I, we examine what you need to know in order to make an informed decision. In Part II, we’ll explore the actual damage mechanisms.

-

O&M

Power 101: Flue Gas Heat Recovery in Power Plants, Part III

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we conclude our three-part series on the essentials of recovering heat from flue gas to dry and process coal, with the goal of improving overall plant operating efficiency.

-

O&M

Improve Furnace Reducing Atmosphere Using Fuel/Air Ratio Control

Progress Energy has incorporated online combustion optimization/tuning to eliminate furnace reducing atmospheres at its Asheville Plant. The optimization project utilized individual burner airflow measurement and continuous burner coal flow measurement to adjust burner air/fuel ratios. The result: significantly improved boiler combustion.

-

O&M

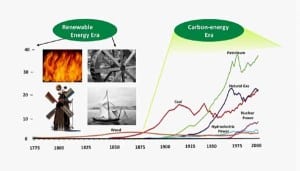

Wind Integration: Does It Reduce Pollution and Greenhouse Gas Emissions?

Many claim that wind generation is beneficial because it reduces pollution emissions and does not emit carbon dioxide. This isn’t necessarily the case. When wind is introduced into a generation system that uses carbon technologies to back up the wind, it actually reduces the energy efficiency of the carbon technologies.

-

O&M

Real-Time Monitoring System Measures Air In-Leakage

The amount of air leaking into the boiler envelope is difficult to estimate. Traditional methods of measuring oxygen at the furnace exit and economizer exit do not account for all types of air leakage. By using molar calculations and total airflow measurement, a good approximation of the total air in-leakage rates of a boiler can be quickly determined using station instruments.

-

O&M

Work Process Optimization: Meeting the Challenge of Change

The competitive push for more efficient power generation prompted the management of East Kentucky Power Cooperative’s Spurlock Station to provide training and to implement standardized work processes in order to achieve higher productivity. To that end, Spurlock’s management collaborated with salaried and hourly personnel to design and implement work process optimization. Two years later, their proactive, operations-driven culture is promoting continuous improvement at this facility.

-

O&M

New Coating System Extends Life of Cooling Tower

American Electric Power’s (AEP’s) Cardinal Power Plant Unit 3 cooling tower in Brilliant, Ohio, was coated and lined in the spring of 2008 by a team of coatings professionals that included the plant’s project and coatings engineering staff, Sherwin-Williams (coatings supplier), Cannon Sline Industrial (contractor), and OTB Technologies (third-party inspector). The team completed the project in just 11 weeks through damp springtime conditions in the Ohio River Valley.

-

O&M

New Process Transforms Waste into Product for Controlling Emissions

In April, Solvay Chemicals Inc. commissioned a new facility that uses an innovative process to recover and transform sodium carbonate waste streams into a market-grade sodium bicarbonate used in air emissions control.

-

O&M

Use Dry Fog to Control Coal Dust Hazards

Fogging systems have been successfully used in the material-handling industry for more than 30 years to control explosive dust at transfer points. Today, fogging systems are an EPA Best Demonstrated Technology for subbituminous coal preparation plants.