O&M

-

O&M

Startup Purge Credit Benefits Combined Cycle Operations

Combined cycle power plants use fuels and other materials that can cause fires or explosions in the combustion turbine, ducting, or heat recovery steam generator. Purging that equipment with ambient air to displace residual combustible gases before starting is a normal safety practice. But when plants are cycled, the disadvantages of purging often outweigh the advantages.

-

O&M

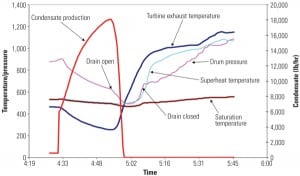

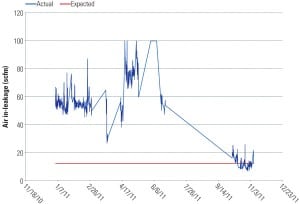

Improve Condenser Performance Through Better Instrumentation

Most power plants use some form of condenser performance-monitoring protocol. Some of those protocols are deficient because the proper instrumentation is not installed to collect the necessary data. Three case studies illustrate how collecting good condenser performance data enabled plant staff to troubleshoot problems and make good plant performance improvement decisions.

-

O&M

Combustible Dust Management Training: Rely on Best Practices, Not Shifting Regulatory Winds

None of you reading this magazine needs an article—or new governmental regulations—to tell you that flash fires and explosions involving coal dust can cause catastrophic incidents, fatalities, facility damage, and financial consequences.

-

O&M

Optimizing Your Coal Ash Recovery Operation

Coal combustion products often can be recycled into a variety of construction and building materials. However, first you must be able to retrieve the wet ash from a holding pond before the ash can be dried and sold.

-

O&M

What Are the Safety Rules for Anyway?

Following safety rules is the foundation to eliminating injuries. Commonly, a safety presenter will say that safety rules are “written in blood.” At one time, such dramatic statements were a way to get attention and illustrated the seriousness of following safety rules. Today, more highly educated workers demand less drama and more facts.

-

O&M

Predictive Maintenance That Works

This is the fifth in a series of predictive maintenance (PdM) articles that began in the April 2011 “Focus on O&M” in which the essentials of PdM were introduced. In the May and June 2011 issues, we explored specific PdM techniques, such as motor-current signature analysis and oil analysis. In the November 2011 issue, we introduced the value of thermographic analysis and its routine use. This installment focuses on ultrasonic and vibration analysis.

-

O&M

Managing the Catalysts of a Combustion Turbine Fleet

Natural gas–fired fleets comprising diverse turbine unit types are operating their units more these days because of the historic low price of natural gas. With increased operating hours, fleet owners are challenged to find the best ways to manage their SCR catalyst systems.

-

O&M

Safe Work Practices in Confined Spaces at Power Plants

Confined space work is often considered to be one of the most dangerous types of work performed in power generation settings. Confined spaces may contain hazardous atmospheres, they can trap entrants, and they generally can increase the hazards associated with otherwise common tasks. When the risks are not recognized, workers all too often regard incidents as surprises, but the hazards of working in confined space can be predicted, monitored, and mitigated. These “accidents” are caused by unsafe conditions, unsafe acts, or both; all accidents are preventable.

-

O&M

Preventing Downtime by Picking the Best Switch Technology

Common fuel-handling problems in the power industry often result in production downtime, costing the owner perhaps up to $200,000 per hour. There are many areas within a coal-fired power plant where mishaps can cause stoppage of material flow. Here we discuss how to select the best switch technology to reduce the possibility of coal flow stoppages.

-

O&M

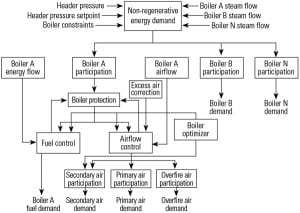

Intelligent Control of FBC Boilers

Optimizing combustion control is critical to reducing emissions and increasing plant operating efficiency, particularly for fluidized bed combustion (FBC) boiler plants burning biomass fuel that has unpredictable moisture content. The secret: measuring actual energy flow.