O&M

-

O&M

Edison Mission Energy Seeks Bankruptcy Protection, Separation from Edison International

Edison International’s unregulated power generating unit Edison Mission Energy (EME) on Monday filed for bankruptcy protection after reaching a reorganization agreement with its parent company and holders of its $3.7 billion in debt to become an entity that is independent of Edison International.

-

O&M

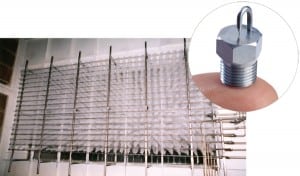

Users Return to Fogging on Frame 7FAs

It has been a decade since an R0 compressor blade was liberated on one of the eight Frame 9FA combustion turbines at CLP Power Hong Kong’s Black Point Power Station. This catastrophic failure eventually led to GE’s recommendation that operators severely limit or cease using online water wash (OLWW), inlet fogging, wet compression, and evaporative coolers on F-Class turbines.

-

O&M

Duke Prepares for Testing at Edwardsport IGCC Plant

Duke Energy said in mid-October that testing was under way in preparation for commercial operation next year of its 630-MW integrated gasification combined cycle (IGCC) Edwardsport power plant in Knox County, Ind.

-

O&M

EPRI: Generation Sector Research Update

This synopsis of today’s most interesting research related to power generation gives you a glimpse of what’s possibly coming to your plant in the not-so-distance future. Research under way today will surely determine how power plants are designed, operated, and maintained for many years to come.

-

O&M

Insulation and Lagging Fundamentals

Insulation and lagging are key to saving energy in a typical steam plant, and plant operators would be well advised to pay close attention to energy losses in their insulation and lagging systems.

-

O&M

Jinzhushan 3: The World’s First PC-Fired Low Mass Flux Vertical Tube Supercritical Boiler, Part 2

The world’s first supercritical pulverized coal–fired low mass flux vertical tube Benson boiler is Jinzhushan 3, located in Hunan Province of the People’s Republic of China. The 600-MW Babcock & Wilcox Power Generation Group Inc. once-through boiler burns Chinese anthracite using downshot pulverized coal (PC) technology. Part 2 of this three-part article discusses the boiler technology. The third and final part will review the plant’s performance test results.

-

O&M

As Cybersecurity Bill Dies, Newly Declassified Report Underscores Grid Vulnerabilities

Despite growing concern about cybersecurity both in and outside of Washington, the Senate’s cybersecurity bill died a second time on Nov. 13. The apparent inability of Congress to pass legislation designed to protect critical U.S. infrastructure could lead to President Barack Obama implementing some of the bill’s provisions via executive order. A day after the bill failed to gain 60 votes for passage, a recently declassified report was released that finds the U.S. power grid is vulnerable to attacks that could be more destructive than natural disasters such as Hurricane Sandy.

-

O&M

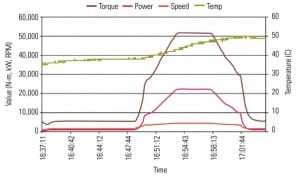

Maximizing Steam Turbine/Compressor Performance with Precise Torque Monitoring at the Coupling

All turbo machinery is subject to degradation that, over time, will affect the system’s efficiency and operational performance. Precise monitoring of turbo machinery performance with continuous torque-monitoring systems can be used to identify gradual efficiency loss. That, in turn, allows a more focused maintenance scope to be developed that can return the system to its optimum operation and efficiency.

-

O&M

Dominion’s North Anna Station Sets New Standard for Earthquake Response

On August 23, 2011, at 1:51 p.m., a magnitude 5.8 earthquake knocked both units at Dominion’s North Anna Power Station off-line—the first time such an event has occurred in the U.S. After 80 days of extensive evaluation and inspection by plant staff and representatives from the U.S. Nuclear Regulatory Commission, both units were back online. What occurred during those days is a remarkable story.

-

O&M

The Evolution of Steam Attemperation

The fundamental design principles and process for modern steam desuperheating, or the attemperation of superheated steam in the power generation industry, have been evolving since the early 1930s. Meeting the requirement for steam quantity, quality, and temperature consistency is the foundation of traditional attemperator component design, particularly for fast-response combined cycle plants.