O&M

-

O&M

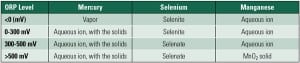

ORP as a Predictor of WFGD Chemistry and Wastewater Treatment

Recent studies have shown that system oxidation-reduction potential (ORP) is not only an important factor for predicting wet flue gas desulfurization (WFGD) absorber chemistry but also may be a predictor of process equipment corrosion and wastewater treatment requirements.

-

O&M

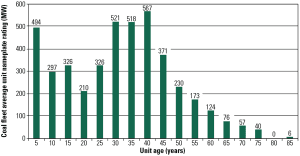

The Case for Utility Boiler Fuel Delivery System Upgrades

A vital part of any coal-fired unit is its fuel delivery system (FDS). A newly formed subcommittee of the ASME Research Committee on Energy, Environment, and Waste has investigated potential FDS upgrades on three typical 500-MW wall-, tangential-, and cyclone-fired boilers. The subcommittee has produced a series of suggested upgrades that have a simple payback of no more than two years.

-

O&M

Fighting Transformer Fires

Transformer fires are fearsome events, perhaps the most dangerous common threats to human life—both onsite and beyond the boundaries of a power plant—that can hit an electric utility.

-

O&M

Fire Protection Guidelines for Handling and Storing PRB Coal

Operators familiar with the unique requirements of burning Powder River Basin (PRB) coal will tell you that it’s not a case of “if” you will have a PRB coal fire, it’s “when.”

-

O&M

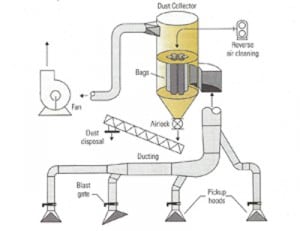

Give Your Plant a Dust Control Tune-Up

Every piece of equipment that transports or processes coal creates some level of particulate matter. Having a strategy for coal dust management in your plant is essential.

-

O&M

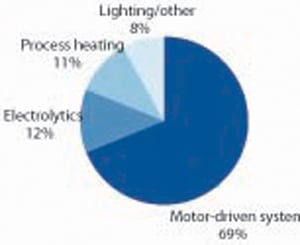

Save Money Using High-Efficiency Motors

Electric motors are the largest energy consumer within a typical industrial plant. Motors also present the greatest opportunity to reduce auxiliary loads, particularly those with high usage factors.

-

O&M

LADWP Harnesses LMS100 to Solve Once-Through Cooling Dilemma

Los Angeles sits alongside the world’s largest body of water, and naturally the city’s Department of Water & Power (LADWP) placed its generating stations along the shoreline to take advantage of that abundant resource for cooling. The LADWP built three coastal generating stations that provide the city with 2,162 MW, about 35% of the peak annual demand.

-

O&M

Improving Warm Weather Performance of the LM6000

The LM6000 is the most widely used aeroderivative combustion turbine (CT) in the world, with more than 1,000 installations. As with all CTs, power output and heat rate degrade markedly during warm weather. The ARCTIC (Absorption Refrigeration Cycle Turbine Inlet Conditioning) system eliminates this deficiency.

-

O&M

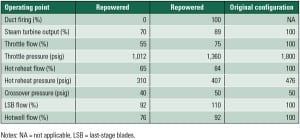

Repower or Build a New Combined Cycle Unit?

URS recently performed a combined cycle repowering study to determine the feasibility and economics of repowering an existing steam turbine that went into service in the 1950s. The competing option was building a new combined cycle unit. The results of the study provide insight for others considering the same alternatives.

-

O&M

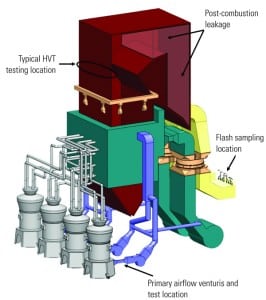

Performance-Driven Maintenance

My career began as a results engineer testing large utility boilers. Ever since that first assignment, I have remained interested in the details of how the measurement and control of the furnace fuel and air inputs can make a huge difference in overall boiler performance. Given that plant operations and maintenance (O&M) budgets are slimmer today than in recent memory, my experience is that targeted performance testing can provide important feedback for prioritizing maintenance expenditures. The combination of plant testing and targeted O&M expenditures provide the best opportunity for efficient and reliable plant operations. I call this approach to plant efficiency improvement “performance-driven maintenace.”