O&M

-

O&M

Wildlife and Power Plants: New Solutions for Animal Problems

Some critters may be cute, but when jellyfish gum up power plant cooling systems; birds, rats, snakes, or squirrels cause electrical shorts; or invasive mollusk species obstruct hydropower plant pipes, losses can be steep. Here’s how some power plant operators are dealing with their critter troubles. There are countless cases of wildlife entering power plant […]

Tagged in: -

O&M

Load Cycling and Boiler Metals: How to Save Your Power Plant

As many coal-fired power plants designed for baseload service are asked to cycle, unforeseen stresses have been introduced to boiler pressure parts. Understanding the effects and implementing mitigation strategies could prevent premature component failure and keep facilities operating reliably. On August 3, 2015, the U.S. Environmental Protection Agency finalized the Clean Power Plan, which calls […]

Tagged in: -

O&M

Ensuring Reliable Boiler Operation Through Proper Material Analysis

Creeped out and fatigued—that’s the state of many coal-fired boilers these days. Understanding failure mechanisms and suitable testing methods for identifying potential trouble can help you find problems before the problems find you. Even as the current regulatory environment pushes new power generation to utilize natural gas over other fuel sources, a significant amount of […]

Tagged in: -

O&M

Minimizing Coal Dust Combustion Hazards: Lessons from Laramie River Station

Coal dust combustion events injured employees and damaged equipment at Laramie River Station in May 2013. Any dust-filled facility could consider implementing some of the plant’s corrective actions to reduce the risk of experiencing a similar incident. When Laramie River Station (LRS), near Wheatland, Wyo., was built nearly 35 years ago, it was state-of-the-art. Constructed […]

-

O&M

Palisades Nuclear Plant Returns to Service After Planned Refueling, Upgrades

Entergy Corp.’s Palisades Power Plant returned to service on Oct. 19, following a month-long outage to implement upgrades, inspections, and safety enhancements. The Michigan plant was shut down on Sept. 16 to begin a planned refueling outage. The company spent $58 million for upgrades and plant inspections, and $63 million for new fuel. The outage […]

-

O&M

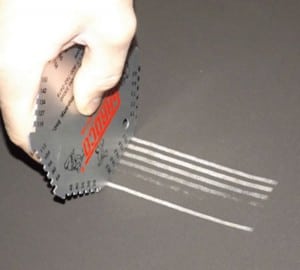

New 3-D Printing System Creates Precision Shaft Collars

Shaft collars are used as stops or locators on shafts in a wide variety of applications. There are two basic types. One uses a setscrew to lock the collar in place, while the other utilizes a clamp-type collar. Shaft Collar Designs Setscrew collars are the oldest type of shaft collar. These units function by gouging […]

Tagged in: -

O&M

High-Performance Synthetic Rope Allows Craneless Wind Turbine Blade Replacement

Replacing blades on a wind turbine is not a simple task. Blades range from 40 to 60 meters in length and can weigh 16 tons or more. Combined with hub heights that can exceed 100 meters and locations that are, by definition, subject to prevailing winds, replacing blades becomes challenging. Add in the cost of […]

Tagged in: -

O&M

ISOs, RTOs Outline Winterization Efforts

In presentations to the Federal Energy Regulatory Commission (FERC), the nation’s regional transmission organizations (RTOs) and independent system operators (ISOs) on Sept. 17 outlined measures they are taking to prevent issues if faced with extreme weather this winter. The measures are to prevent widespread generation outages as occurred during the Jan. 6–7, 2014, polar vortex. […]

-

Legal & Regulatory

Duke Energy Settles with Groups Over Edwardsport Operating Costs

Duke Energy Indiana reached a settlement agreement with some of the state’s key consumer groups related to operating costs at its Edwardsport integrated gasification combined cycle (IGCC) coal power plant. The deal was submitted to state regulators on Sept. 18 and is subject to Indiana Utility Regulatory Commission (IURC) approval. If approved, it would resolve […]

-

Partner Content

Case Study: Exelon Ensures Nuclear Power Plant Safety Using Online Monitoring

Exelon has optimized the efficiency of its operations, maintenance, and engineering staff. By automating data collection, plant engineers now focus on analyzing data rather than manually collecting data and risking radiation exposure. Download this case study to get more details then go here to learn more about Condition Based Maintenance (CBM) for Power Generation.