Gas

-

O&M

BIG PICTURE: Lights Out (Web Supplement)

A web supplement to the September issue with details of global power shortages.

-

Gas

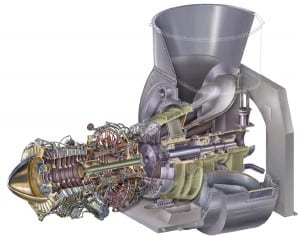

E.ON Commissions 433-MW Hungary CCGT

Two years after it laid the foundation stone, Germany’s E.ON on June 27 opened Hungary’s most efficient combined cycle gas turbine (CCGT) power plant (Figure 7). The €400 million ($573 million) plant in Gönyü has a capacity of 433 MW and an efficiency of over 59%, E.ON claims. Siemens supplied the main components: an SGT5-4000F gas turbine, an SST5-5000 steam turbine, an SGEN 5-3000W generator, and the entire electrical and instrument and control equipment. The natural gas–fired power plant is of single-shaft design with the main components arranged in a single driveline.

-

O&M

Marmaduke Award: CFE Extends CTG Universidad Unit 2’s Life with Conversion to Synchronous Condenser

CTG Universidad is a two-unit combustion turbine plant commissioned in late 1970 by the Comisión Federal de Electricidad (CFE) on the north side of Monterrey, Mexico’s third-largest city and an important industrial center. By the 1990s, the two 14-MW turbines were obsolete, used sparingly, and slated for demolition in 2010. However, by 2002, portions of Monterrey began experiencing power restrictions caused by a lack of sufficient reactive power production, and that situation presented an opportunity for the plant. By repurposing an old combustion turbine for use as a synchronous condenser to provide local reactive power, CFE significantly reduced local power supply limitations. For that savvy plant repurposing, CFE’s CTG Universidad Unit 2 is the winner of POWER’s 2011 Marmaduke Award for excellence in power plant problem-solving. The award is named for Marmaduke Surfaceblow, the fictional marine engineer and plant troubleshooter par excellence.

-

O&M

Make Your Plant Ready for Cycling Operations

Cycling your steam power plant is inevitable, so now is the time to learn how to minimize equipment damage and assess the true costs of cycling. Whether cycling is required by the grid operator because of renewable integration or other factors, you must be proactive about updating operating processes and upgrade equipment so the transition to cycling operation goes smoothly.

-

O&M

Mitigating the Effects of Flexible Operation on Coal-Fired Power Plants

As coal-fired power plants increasingly operate in cycling modes, many plants are confronting the potential for higher levels of component damage and degraded performance of environmental control equipment. Generators and EPRI are working together to find ways to mitigate the effects of cycling operation and to manage the transition of formerly baseload plants to flexible operation.

-

Gas

Alstom Launches Upgraded GT26

Just as GE Energy, Siemens, and Mitsubishi Heavy Industries (MHI) in May announced gas combustion technology developments—each seeking to push the 60% barrier with new gas turbine designs—Alstom has quietly been upgrading its KA26 combined cycle power plant. (See the July 2011 “Global Monitor” for more information on the GE, Siemens, and MHI turbines.) The firm says that the next generation of the 500-MW power plant, based on the advanced class GT26 gas turbine, features “achievable” efficiencies of over 61%, increased flexibility, and more than 350 MW, which can be delivered in less than 15 minutes to help integrate renewable energy sources (Figure 3).

-

Gas

Pushing the 60% Efficiency Gas Turbine Barrier

Gas turbine makers GE, Siemens, and Mitsubishi Heavy Industries (MHI) in the last week of May separately profiled unprecedented results from development or testing of three innovative combined-cycle gas turbine (CCGT) technologies.

-

Coal

Using Fossil-Fueled Generation to Accelerate the Deployment of Renewables

It may seem counterintuitive, but the strategic coupling of simple- and combined- cycle technologies with renewable generation could establish the conditions necessary for adding more renewable megawatts to transmission grids around the world.

-

Coal

Consolidation, Market Distortions Underlie Remarks by Industry Executives

If you needed additional proof that the power industry is changing, the ELECTRIC POWER keynote and panel discussions over the past few years have provided it—top-of-mind issues have been significantly different each year. For the 2011 keynote speaker and panelists, the challenges of reliability, regulatory compliance, financing, and getting the fuel mix right took center stage. In the wake of Japan’s nuclear crisis, safety also featured prominently.

-

Coal

Spain: A Renewable Kingdom

Spain has served as both exemplar and scapegoat when it comes to renewable energy policy. Though power policy must necessarily accommodate specific national resources and goals, Spain’s experience as an early and eager adopter of renewable energy technologies and subsidies is a cautionary tale of how the best intentions can have unintended consequences.

-

Gas

The T-Point Plant: The Ultimate Validation Test

Fourteen years ago, the MHI T-Point demonstration combined-cycle plant in Takasago, Japan, changed the way modern gas turbines are validated under real operating conditions. In February, T-Point marked yet another milestone by starting to validate the world’s largest and highest efficiency gas turbine, which operates at the unprecedented turbine inlet temperature of 1,600C.

-

Gas

Selecting Your Next Combustion Turbine

With natural gas serving as the fuel de jour, many utilities and merchant generators will be considering the purchase of new combustion turbines in the near future. If you are in the market for a gas turbine, here are some key design features you should discuss with turbine vendors prior to your next purchase.

-

Gas

Sendai Plant Boosts Efficiency and Cuts Emissions

Located on the scenic Japanese coastline, Tohoku Electric Power Co., Inc.’s new 446-MW Sendai Thermal Power Station Unit 4 is a combined-cycle plant that replaces three 175-MW coal-fired units that had been in operation for more than 50 years. The new plant features the first application of MHI’s 50-Hz M701F4 gas turbine, which provides a thermal efficiency boost from the old plant’s 43% to more than 58%. This change substantially reduces CO2 emissions.

-

Gas

E.ON Starts 417-MW Cogeneration Plant in Slovakia

At the beginning of 2011, German firm E.ON began operation of its new 417-MW Malzenice gas and steam turbine power station in Slovakia’s Trnava region, near the country’s capital, Bratislava (Figure 5). The facility, which is expected to generate more than 300 billion kWh annually, boasts an efficiency of 58%—which E.ON claims is among the “highest in Europe.”

-

Gas

Using Flue Gas to Mitigate Ocean Acidification

Lab-scale experiments have shown that seawater and calcium could effectively remove most of the carbon dioxide (CO2) from a natural gas power plant’s flue gas stream. A large fraction of the captured gas could then be converted into dissolved calcium bicarbonate—which, pumped into the sea, could be beneficial to the ocean’s marine life, says a researcher representing both the Lawrence Livermore National Laboratory’s (LLNL’s) Carbon Management Program and the University of California, Santa Cruz.

-

Coal

Canada’s “Clean” Image Extends to Clean Power

Canada’s extensive natural resources are the driver of its powerful economy, and energy is Canada’s single most important export. Yet policy makers across the nation are currently dealing with the consequences of a generation of under-investment in the electricity system and deciding what the new grid and supply mix should look like. Several provinces are competing to lead the charge in renewable energy and grid intelligence. Policy makers hope that such efforts will not only provide for Canada’s electricity needs but also create the green economy jobs that will drive the nation’s next generation of economic development.

-

Coal

Canada’s Provincial Power Strategies

In Canada, as in the U.S., where you live determines the type of generation technology that provides your power. Here’s how the four most energy-intensive provinces in Canada are responding to the challenge of providing reliable and cheap power in a sustainable way.

-

Gas

RAM Process Optimizes IGCC Design

New methods of reliability, availability, and maintainability (RAM) evaluation help facilitate more-accurate plant output and revenue predictions, identify strengths and weaknesses of possible plant configurations, and determine potential improvements and enhancements for integrated gasification combined cycle plants.

-

Coal

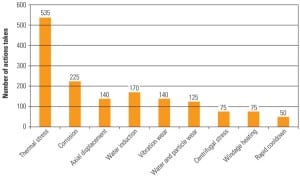

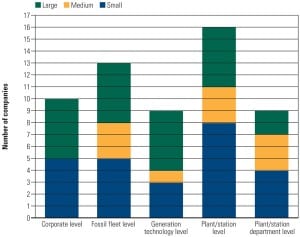

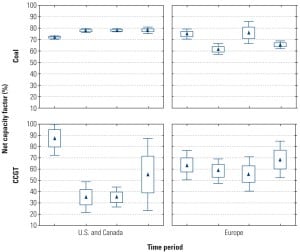

Benchmarking Fossil Plant Performance Measures, Part I: Station-Level Metrics

How does your company prepare and share fossil plant performance data? What data are important, and how much effort is required to collect and report the data? What are the most important statistics for reporting key fossil plant operations? The latest EUCG benchmarking survey reveals the favored fossil performance metrics at several of the largest utilities in eight key categories.

-

Gas

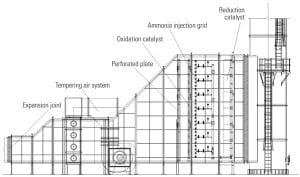

Automated Exhaust Temperature Control for Simple-Cycle Power Plants

A common concern for gas turbine power plants is treating exhaust gases to comply with laws restricting pollutants present in the gases that are emitted into the ambient atmosphere. The challenge for designers is to control the exhaust gas operating temperature within a range that maximizes performance of the oxidation and reduction catalysts.

-

Coal

Coal Plants Challenged as Gas Plants Surge

European carbon trading is gradually pushing down coal-fired capacity factors, and operating costs are rising. The U.S. may not have a carbon market, but increasing regulatory requirements are having the same effect on coal-fired generation capacity factors and operating costs. In the meantime, gas-fired assets are enjoying increased usage and lower unit costs.

-

Coal

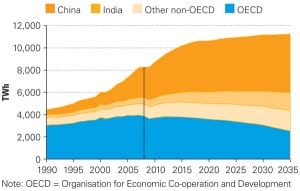

IEA: Global Power Demand to Surge 2.2% Annually Through 2035

Though electricity generation has entered a key period of transition—as investment shifts to low-carbon technologies—world electricity demand is set to grow faster than any other “final form of energy,” the International Energy Agency (IEA) says in its latest annual World Energy Outlook.

-

Gas

MHI Prepares to Test J-Series in Japan

Mitsubishi Heavy Industries (MHI) has begun converting a combined-cycle plant in Japan to prepare for verification testing of its long-anticipated J-Series gas turbine in February 2011—a system that the company claims has the most power generation capacity and highest thermal efficiency in the 1,600C turbine inlet temperature class (Figure 3). The work being carried out at the Takasago Machinery Works facility in Hyogo Prefecture (where the company’s G-Series gas turbines were tested) includes installation of the J-Series turbine, and it marks another major milestone in the technology’s development.

-

Gas

TransCanada Opens 683-MW Halton Hills Combined-Cycle Plant

TransCanada Corp. on Oct. 28 officially opened its C$700 million Halton Hills Generating Station. The 683-MW 2 x 1 combined-cycle plant on a greenfield site in Ontario (Figure 5) will operate under a 20-year power purchase agreement with the Ontario Power Authority (OPA). Construction of the peaker plant started in December 2007 and was completed on time and on budget, TransCanada said.

-

Coal

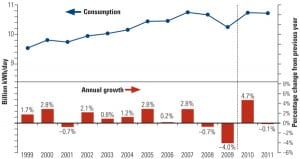

The U.S. Power Industry 2011: The Sequel

If Hollywood were scripting the power industry story for 2011, it would be a sequel to 2010—more of the same, but just not quite as good. Natural gas gets top billing and the accolades, wind power drops to a supporting role, and new nuclear answers the casting call but has yet to get a speaking part. Coal is like Mel Gibson—a talented Oscar winner unlikely to get another leading role. In this, our fifth annual industry forecast report, the story may be familiar, but the price of admission is going way up.

-

Gas

Turkey Opens Record-Breaking Combustion Gas Engine Plant

Turkey, a country that has seen rapid economic growth since the 1980s, largely spurred by a shift in governmental strategy to open up markets and increase private participation, has been actively overhauling its power infrastructure to meet soaring electricity consumption. According to grid operator Turkish Electricity Transmission Co., national consumption increased to 17 billion kWh this September—an 11% increase over the 15.3 billion kWh consumed in September 2009.

-

Gas

GE Launches 9.5-MW Engine for Distributed Generation

A 9.5-MW gas engine unveiled by GE this October for decentralized, independent power producers in remote, hot, or high-altitude regions features a 48.7% electrical efficiency and promises to reduce lifecycle costs by lowering fuel consumption.

-

O&M

NFPA Gas Purging Rules Updated

The CSB has made urgent recommendations to the NFPA and the International Code Council to prohibit indoor purging and require companies and installers to purge flammable fuel gases to safe locations outdoors, away from workers and ignition sources.

-

Gas

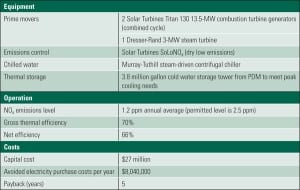

Smart Power Generation at UCSD

The University of California, San Diego has been accumulating awards for its savvy use of a constellation of power generation and energy-saving technologies. The campus already controls a fully functioning microgrid—including a cogeneration plant—and, as befits a research institution, is constantly looking for new ways to make its energy system smarter. This “living laboratory,” as campus leaders like to call it, demonstrates what it takes to build a smarter grid and why the effort is worth it.

-

Gas

Microturbine Technology Matures

Microturbine technology has evolved from early systems of 30 kW to 70 kW to today’s systems, which can have individual ratings of 200 kW to 250 kW. Packages up to 1 MW are now available that can be assembled into multipac units for projects of 5 MW to 10 MW. These modern units are packaged with integrated digital protection, synchronization, and controls; they produce high combined heat and power efficiencies; and they are capable of using multiple fuels.