Gas

-

Gas

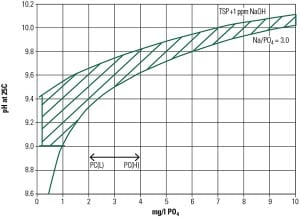

Selecting a Combined Cycle Water Chemistry Program

The lifeblood of the combined cycle plant is its water chemistry program. This is particularly true for plants designed for high pressures and temperatures as well as fast starts and cycling. Even though such plants are increasingly common, no universal chemistry program can be used for all of them.

-

O&M

Steam Turbine Blade Reverse Engineering, Upgrade, and Structural Design

Steam turbine blade cracking often suggests the need for an upgraded blade design. Follow the process of reversing engineering a failed blade to produce a more reliable and efficient design.

-

Commentary

Biogas: An Alternative Energy Source

Most professionals in the energy industry know about biomass; fewer of us are conversant with biogas. This commentary explains the basics of biogas, with a focus on its current use and future potential as a source of electrical power.

-

Gas

Japan Banks on LNG

Japan’s scramble to replace generation lost from nuclear power plants that were shuttered after the March 2011 Fukushima Daiichi nuclear accident has forced it to rely on pricey imports of fossil fuels—and soaring energy costs are hammering the world’s third-largest economy.

-

Coal

EPA Directs 36 States to Revise SIPs for Emissions during Plant Startup, Shutdown, Malfunction

A rule proposed by the Environmental Protection Agency (EPA) directs 36 states to revise their Clean Air Act State Implementation Plans (SIPs) to eliminate exemptions for excess emissions of air pollutants at power plants during startup, shutdown, or when the plant malfunctions.

-

Coal

Senators Introduce “Carbon Fee” Bill, House Dems Call for Blue Ribbon Climate Panel

Boosted by President Obama’s inaugural address commitment to mitigate climate change, congressional Democrats have initiated several more climate measures. A legislative packet that seeks to mitigate climate change by enacting a carbon "fee" of $20 per ton of emitted carbon or methane equivalent was introduced last week by Sens. Bernie Sanders (I-Vt.) and Barbara Boxer (D-Calif.). In the House, as several Democratic amendments for climate change hearings were voted down, more than 40 lawmakers urged President Obama to create a panel that would help communities deal with climate change events.

-

Coal

Obama Calls for Market-Based Climate Change Solution in SOTU

President Obama outlined a number of key energy-related measures in his State of the Union speech on Tuesday night, urging Congress to pursue legislation to mitigate climate change and calling for an expansion of clean energy and reduced red-tape for natural gas and oil permits.

-

Coal

Minn. Power Considers Fuel Switch, Coal Unit Retirement to Comply with Fed, State Mercury Rules

A newly announced resource strategy could require Duluth, Minn.–based Minnesota Power to convert its 110-MW Laskin Energy Center in Hoyt Lakes, Minn., to a natural gas peaking facility in 2015, install environmental upgrades at its 558-MW Clay Boswell Energy Center Unit 4 in Itasca County, and retire one of three coal-fired units at its 225-MW Taconite Harbor facility in Schroeder.

-

Coal

Low Gas Prices Prompt Duke to Retire Coal Units Two Years Early

Citing low natural gas prices, Duke Energy announced on Feb. 1 that it would shutter its 1920s-built Buck and Riverbend stations two years before the coal-fired plants were slated for retirement. The company had chosen to retire the plants just before April 2015, which is the compliance deadline for recently enacted federal environmental rules.

-

O&M

Layup Practices for Fossil Plants

Improper layup practices are a major contributor to boiler tube failures and to steam turbine pitting and cracking in U.S. fossil plants. EPRI’s research into identifying damage mechanisms, utility best practices, and innovative new methods to protect plant equipment during outages will aid plant operators in achieving a successful layup.