Coal

-

Coal

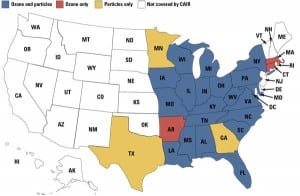

Emissions: Clean Air Interstate and Clean Air Mercury Rules: An Overview

Utility customers depend on and expect reliable, affordable electricity for virtually every aspect of their lives. At the same time, electricity producers in the United States are faced with finding cost-effective methods to meet ever-increasing demand and more stringent environmental regulations. Though it’s not a new trend, the frequency with which new regulatory air quality […]

-

O&M

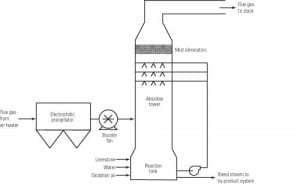

Scrubbing: Optimizing Flue Gas Desulfurization Technologies Is Essential

New flue gas desulfurization (FGD) units are being installed at utilities in many parts of the U.S. and a large percentage of the new scrubbers are of the wet limestone type. Although wet limestone scrubbing is a well-developed technology, it may be unfamiliar to employees at plants that have previously not required scrubbers. This article […]

-

O&M

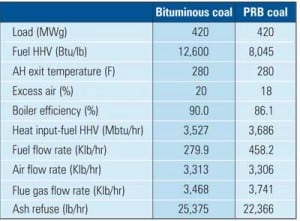

Boiler Conversion: Converting a Boiler from Burning Bituminous Coals to PRB Coals Can Be a Challenge

Design techniques and operating experience with Powder River Basin (PRB) coals have advanced significantly over the past 35 years for boilers that were originally designed for this fuel. Today, boiler installations looking to effectively utilize PRB coals fall into two primary categories: units that were initially designed for bituminous or other coals and units that […]

-

O&M

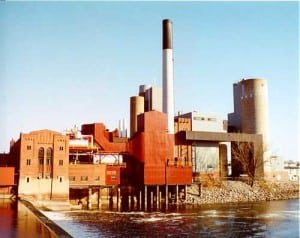

Case Histories: Co-Firing Coal and Oat Hulls Reduces Emissions at University Power Plant

The University of Iowa (UI) Biomass Fuel Project has produced significant reductions in greenhouse gas emissions, regulated boiler stack emissions, and purchased energy costs. The project utilizes a renewable, biomass fuel source and provides an opportunity for UI to partner with a local industry. UI was approached by Quaker Oats Co., Cedar Rapids Facility in […]

-

O&M

Case Histories: Asheville Power Station’s Retrofit First to Meet North Carolina’s Clean Smokestacks Act

Asheville Power Station’s Unit 1 in Arden, North Carolina, was the first coal-fired unit to be modified with a flue gas desulphurization (FGD) system and placed in service to meet the clean air requirements of the state’s Clean Smokestacks Act. As of November 16, 2005, at least 97% of the sulfur dioxide that had been […]

-

O&M

Case Histories: Synthetic Oil and Enhanced Filtration Reduce Wear and Extend Gear Life

A coal-fired power plant operating in the western U.S. was experiencing short gearbox life in its coal-pulverizing operation. After an annual gearbox inspection, oil analysis results indicated that the AGMA 6EP (ISO 320) gear oil recommended by the original equipment manufacturer (OEM) had failed to provide adequate lubrication and protection. This conclusion was based on […]

-

Coal

Coal Users Community: Growth Is the Byword for Gasification

The Gasification Technologies Council (GTC, www.gasification.org) was created in 1995 with a straightforward mission: to promote the greater use of gasification as an environmentally and economically preferred alternative for the production of power, fuels, and chemicals from low-value energy sources. Those energy sources include high-sulfur coal, petroleum coke, and wastes. Since that time the GTC […]

-

O&M

Projects

Reliant Energy Commits $350 Million for Environmental Upgrades at Two Key Facilities Reliant Energy has announced plans to install state-of-the-art emission control systems at two Pennsylvania power plants, a major step in the company’s strategy for maximizing the long-term value of its power generation assets while reducing air emissions. The utility, Reliant Energy, estimated it […]

-

Coal

Bethlehem Energy Center, Glenmont, New York

A great location, a fish-friendly cooling system, and the extent of environmental remediation needed to permit it distinguish this repowering project on the Hudson River just south of the New York State capital.

-

Coal

Currant Creek Power Plant, Mona, Utah

Commercial operation of PacifiCorp’s first new power plant in more than 20 years coincided with the company’s acquisition by MidAmerican Energy Holdings Company this past March. Currant Creek treads lightly on the environment, provides needed power to PacifiCorp’s eastern control area, and has demonstrated its commitment to be a good corporate citizen of the local community. By any account, Currant Creek is a model for how to develop a power project.