Coal

-

O&M

Apply the fundamentals to improve emissions performance

The O&M staff of AES Westover Station wisely took a holistic approach to optimizing combustion within Unit 8’s boiler in order to reduce its NOx emissions while maintaining acceptable levels of carbon-in-ash content. The results of major modifications—centered on the addition of a fan-boosted overfire air system—were a 60% reduction in NOx levels, improved unit reliability, and a project payback period measured in months rather than years. As this project proved, the whole is more than the sum of its parts.

-

Coal

Designing and upgrading plants to blend coal

Fuel flexibility isn’t free. Whether you’re equipping a new power plant to burn more than one type of coal or retrofitting an existing plant to handle coal blends, you’ll have to spend time and money to ensure that all three functions performed by its coal-handling system—unloading, stockout, and reclaim—are up to the task. The first half of this article lays out the available options for configuring each subsystem to support blending. The second half describes, in words and pictures, how 12 power plants—both new and old—address the issue.

-

Coal

Expert systems optimize boiler performance, extend plant life

Slagging and fouling of furnaces and boilers’ convective pass top the list of costly coal plant O&M problems. Although sootblowing is a tried and true solution, running sootblowers too often can erode boiler tubes. Lehigh University’s Energy Research Center has developed an "expert" sootblowing system that has outperformed experienced operators’ "seat of their pants" sootblowing procedures on two head-to-head field tests.

-

Coal

Utilities split on readiness of IGCC

For some gencos, the dearth of operating experience for integrated gasification combined-cycle plants adds too much uncertainty to the risk/reward equation for new-capacity technology options. For others, the possibility of being able to comply with air pollution limits as far out as 2018, as well as to meet all-but-certain CO2 caps, makes IGCC well worth investing in—now.

-

Coal

Technology options for capturing CO2

Concerns about global climate change have prompted interest in reducing or eliminating the carbon dioxide (CO2) emissions of fossil fuel-fired power plants. Here’s a guide to the technology and economics of three CO2 capture methods: postcombustion separation of CO2 from flue gas (applicable to existing plants), and oxygen-fired combustion and precombustion capture (suitable for new coal-fired capacity, including IGCC plants).

-

Coal

Tri-State Generation and Transmission Association’s Springerville Unit 3 earns POWER’s highest honor

It’s said that pioneers take the arrows. In the case of Springerville Unit 3—a 418-MW (net) expansion of a Tucson Electric Power facility in Arizona and the first pulverized coal–fired unit built in the U.S. in more than a decade—the arrows were many. Although Tri-State (the developer), Tucson Electric (the host), and Bechtel Power (the EPC contractor) were wounded by delayed deliveries of major equipment, bankruptcy of a major supplier, and a labor shortage, the companies showed their pioneering spirit and completed the project ahead of schedule. For ushering in a new generation of clean and desperately needed baseload capacity, Springerville Unit 3 is POWER magazine’s 2006 Plant of the Year.

-

Coal

Nova Scotia Power’s Point Aconi plant overcomes CFB design problems to become rock of reliability

Point Aconi’s circulating fluidized-bed boiler experienced erosion, corrosion, and fouling problems from the day it went on-line in 1993. After several frustrating years of unreliable operation, in late 1999, Nova Scotia Power discovered the right combination of engineering and fuel modifications. Today, after a switch to 80% petroleum coke and major boiler modifications, Point Aconi’s output exceeds its original nameplate rating. For having the vision and fortitude to plan and execute a multiyear, $20 million project to revitalize North America’s first in-service utility CFB boiler, Nova Scotia Power’s Point Aconi plant is the well-deserved winner of POWER magazine’s 2006 Marmaduke Award for excellence in O&M.

-

Coal

How accurate are your reported emissions measurements?

Complying with permitted emissions limits may be the most significant operations risk for a power plant. As limits are slowly ratcheted downward, understanding the accuracy and variation of measured pollutant levels becomes even more important. To avoid misunderstandings, regulators and plant owners should factor measurement uncertainty into air quality permit numbers both as the permit is formulated and preceding any subsequent modifications.

-

Coal

Global Monitor (September 2006)

Demand records fall nationwide;

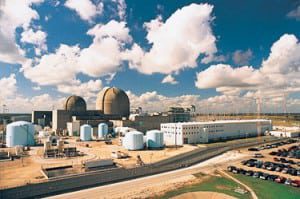

GE’s ABWR to be STP’s edge; Entergy buys Palisades plant; Dithering over desert disposal; Tourist trash-to-energy plant;

Brooklyn says "Yo!" to microturbines; POWER digest -

O&M

Case Histories: Asheville Power Station’s Retrofit First to Meet North Carolina’s Clean Smokestacks Act

Asheville Power Station’s Unit 1 in Arden, North Carolina, was the first coal-fired unit to be modified with a flue gas desulphurization (FGD) system and placed in service to meet the clean air requirements of the state’s Clean Smokestacks Act. As of November 16, 2005, at least 97% of the sulfur dioxide that had been […]