Coal

-

Coal

PRB Tech Notes: New Plant/Old Plant: Are We Applying What We’ve Learned?

In the last issue of COAL POWER, I urged readers to give coal handling the priority it deserves. The coal yard warrants as much attention as boilers and combustion systems, turbine-generators and auxiliaries, and postcombustion emissions control — the other three "zones" within the plant perimeter — because it is an equally valuable business unit. […]

-

O&M

To optimize performance, begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with problems similar to yours.

-

O&M

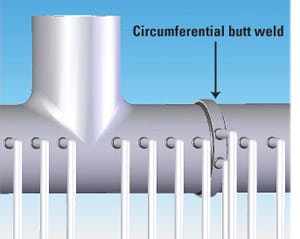

Finding and fixing cracks in high-temperature headers

The welds on superheater and reheater headers are arguably the most stressed parts of a modern steam plant. For that reason, it’s surprising that they also may be the most under-inspected. Cracks are rare, but they can be repaired if found early. One plant avoided a long forced outage to replace a reheater outlet header by using the correct condition assessments and welding techniques.

-

O&M

SO3’s impacts on plant O&M: Part II

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operation and maintenance of back-end plant equipment. In this issue, we list and quantify the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. Part III—to appear in the April 2007 issue—will describe the characteristics of an optimal SO3 removal technology and present the technical details and operating experience of one patented process that has worked successfully at a half-dozen plants for up to three years.

-

Coal

Sealing abandoned mines with treated flyash kills two birds with one stone

Environmentally benign disposal of coal combustion products/by-products (CCPs) such as flyash and bottom ash has been a problem since the first coal-fired power plant went on-line. In recent years, ways have been developed to recycle CCPs into useful commercial products like bricks and roadbase. This article describes an innovative State of Maryland program that is putting CCPs to yet another use: stabilizing abandoned mines to permanently sequester acids and harmful metals.

-

Coal

NOx, SO3 in the spotlight at NETL’s 2006 Environmental Controls Conference

As emissions caps drop, technological solutions must become increasingly effective and efficient. Researchers, equipment vendors, and plant operators are exploring alternatives to SCR and SNCR, with a view to reducing the overall costs of NOx reduction. They’ve also achieved 95% to 99% removal of SO3, with no visible plume opacity.

-

Coal

Global Monitor (January 2007)

DOE walks the clean coal talk / For Swedish nuke, a case of mistaken identity / Siemens completes big CHP plant / E.ON bets big on coal / BP Solar expands Maryland plant / GE scores big turbine deals / PSNH switches from coal to wood / EPRI tests solid-state current limiter / POWER digest

-

Coal

Investment in generation is heavy, but important needs remain

Forecasting the direction of the U.S. electric power industry for 2007, much less the distant future, is like defining a velocity vector; doing so requires a direction and speed to delineate progress. In this special report, POWER’s first stab at prognostication, the editors look at current industry indicators and draw conclusions based on their more than 100 years of experience. To borrow verbatim the title of basketball legend Charles Barkley’s book: I May Be Wrong but I Doubt It.

-

Coal

Near-term capital spending in the North American power industry

Following the money invested in projects is a viable way to compare growth trends for power projects using the four major generation types: coal, natural gas, nuclear, and renewable.

-

Coal

Speaking of Coal Power: Shedding More Heat Than Light

When Charles Dickens began A Tale of Two Cities with, "It was the best of times, it was the worst of times," he was referring to the French Revolution of the late 18th century. But Dickens’ words apply equally well to the American generation industry of the late 20th century. A decade of overbuilding U.S. […]