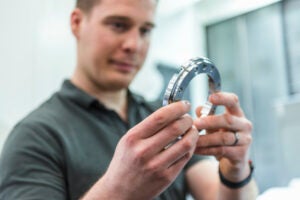

Carbon seal rings are silently revolutionizing industries—from oil rigs to rocket engines. Carbon seal rings can have significant effects. Take a recent upgrade by ExxonMobil. By switching to advanced carbon seals in refineries, the company cut fugitive emissions by almost 30% and saved millions of dollars in downtime. Or SpaceX, which relies on ultra-durable carbon-graphite seals to handle the punishing heat of rocket re-entries.

The market is also heating up with greater opportunities in renewable energy applications. The market experts from Research Nester project that the market, which was valued at about $3.16 billion in 2024, will reach $6.03 billion by 2037, growing at a compound annual growth rate (CAGR) of 5.1%. Startups are innovating with self-lubricating coatings and artificial intelligence (AI)-monitored smart seals, while John Crane and EagleBurgmann, two industrial giants, battle for dominance. Here’s what’s in store for the market.

Innovations Defining Carbon Seal Rings: What’s New?

The carbon seal game is leveling up fast, thanks to some seriously smart upgrades. Recent innovations in carbon seal rings are changing how industries approach sealing solutions.

Material Advancements. Carbon-graphite composites are now used for better thermal stability, while ceramic-infused carbon offers extra hardness and wear resistance. Resin-impregnated carbon has also emerged as a strong option, giving longer service life in high-load environments. One of the most talked about launches in recent years was John Crane’s SIGMA S6M carbon-graphite seal faces. The design is specifically made for mechanical seal faces in demanding applications, including for use in chemical processing, oil and gas, power generation, and water treatment industries.

Upgraded Tech Development. The development of seal rings has encountered many transformations. Precision CNC (computer numerical control) machining is a technique that makes the seals more capable of withstanding harsh weather or tough conditions. Want to know an instance of this? Let’s talk about how Flowserve used five-axis CNC machining to produce ultra-precise carbon-graphite seals for Westinghouse’s AP1000 nuclear reactors. Moreover, additive manufacturing, including 3D printing, allows production of custom seals faster, especially for rare or complex equipment where traditional production would take weeks.

Updated Performance. To resist extreme environments, modern seals are developed using high-temperature resistance, low-friction coatings to reduce energy loss. There are also corrosion-resistant designs for use in aggressive chemical settings. For instance, Baker Hughes’ turbine seals launched in May 2022 use nano-ceramic carbon to withstand 1,500F inside next-generation gas turbines, extending service life by more than 40%.

These kinds of advancements show how carbon seal rings are no longer basic components but a high-tech solution that helps industries to work properly. And all these demonstrate why investors are becoming highly interested in investing in these innovations.

Regulatory Support Pushing the Market Even Further

The carbon seal ring industry is getting bigger as regulatory bodies are coming up with stricter rules intended to help achieve zero emissions goal. Updates in ISO (International Organization for Standardization), ASME (American Society of Mechanical Engineers), and ASTM (American Society for Testing and Materials) guidelines now focus more on leak prevention, durability, and efficiency, pushing manufacturers to adopt advanced designs. Environmental compliance rules are also encouraging the use of sustainable materials like eco-friendly resin and recycled carbon composites.

For instance, recent European Union green initiatives have accelerated the push for modern sealing technologies, prompting industries to replace outdated components to meet stricter environmental standards. This shift has significantly increased demand for carbon-graphite rings, opening new market opportunities as companies align with sustainability goals.

Meanwhile, sustainable materials are replacing traditional ones. For instance, recycled carbon fiber seals now meet ASTM D7775, while bio-resin-pollinated rings cut cradle-to-grave emissions by around 60%.

What Is the Investment Opportunity?

As carbon seal rings are highly reliable, they are a highly sought-after component in various sectors. In heavy-duty industries, there is a higher demand for replacement of components, which induces the demand for carbon seal rings. Various public and private entities are investing massive amounts to develop more effective carbon seal rings. For instance, the U.S. Department of Energy (DOE) allotted more than $5 million to a program to develop eco-friendly carbon composites. Again, Siemens and TURN2X teamed up in May 2025 to increase green energy production.

The carbon seal industry is going through a massive change. Material inventions, manufacturing accuracy, and strict government rules will make this industry a multi-billion-dollar one in the future. As automation takes the whole game to the next level with higher precision and speed, the demand will only increase, and it’s high time for investors to grab the opportunity.

—Aashi Mishra is a senior content writer with Research Nester.