-

Legal & Regulatory

Restricting bids for new capacity raises costs, lowers reliability

Most sponsors of bid solicitations seek to attract the maximum number of high-quality bids. Basic economic principles tell us that the greater the number of respondents to a solicitation, the greater the competition and the greater the benefits to the solicitor. Somewhat counterintuitively, and notwithstanding California’s need for more electricity supply, the state’s utilities are […]

-

O&M

Apply the fundamentals to improve emissions performance

The O&M staff of AES Westover Station wisely took a holistic approach to optimizing combustion within Unit 8’s boiler in order to reduce its NOx emissions while maintaining acceptable levels of carbon-in-ash content. The results of major modifications—centered on the addition of a fan-boosted overfire air system—were a 60% reduction in NOx levels, improved unit reliability, and a project payback period measured in months rather than years. As this project proved, the whole is more than the sum of its parts.

-

Coal

Designing and upgrading plants to blend coal

Fuel flexibility isn’t free. Whether you’re equipping a new power plant to burn more than one type of coal or retrofitting an existing plant to handle coal blends, you’ll have to spend time and money to ensure that all three functions performed by its coal-handling system—unloading, stockout, and reclaim—are up to the task. The first half of this article lays out the available options for configuring each subsystem to support blending. The second half describes, in words and pictures, how 12 power plants—both new and old—address the issue.

-

Coal

Expert systems optimize boiler performance, extend plant life

Slagging and fouling of furnaces and boilers’ convective pass top the list of costly coal plant O&M problems. Although sootblowing is a tried and true solution, running sootblowers too often can erode boiler tubes. Lehigh University’s Energy Research Center has developed an "expert" sootblowing system that has outperformed experienced operators’ "seat of their pants" sootblowing procedures on two head-to-head field tests.

-

Coal

Utilities split on readiness of IGCC

For some gencos, the dearth of operating experience for integrated gasification combined-cycle plants adds too much uncertainty to the risk/reward equation for new-capacity technology options. For others, the possibility of being able to comply with air pollution limits as far out as 2018, as well as to meet all-but-certain CO2 caps, makes IGCC well worth investing in—now.

-

Coal

Technology options for capturing CO2

Concerns about global climate change have prompted interest in reducing or eliminating the carbon dioxide (CO2) emissions of fossil fuel-fired power plants. Here’s a guide to the technology and economics of three CO2 capture methods: postcombustion separation of CO2 from flue gas (applicable to existing plants), and oxygen-fired combustion and precombustion capture (suitable for new coal-fired capacity, including IGCC plants).

-

O&M

Meeting utility industry challenges through innovation

In 2005, Xcel Energy fully implemented its unique Utility Innovations initiative to encourage its IT vendors to work together. One pilot project completed under the UI umbrella confirmed that tighter integration of predictive and analytical systems and data can optimize preventive maintenance intervals, reducing costs and downtime while increasing profits and productivity.

-

News

National pastime

—Dr. Robert Peltier, PE Editor-in-Chief During every summer hot enough to break peak demand records, the rhetoric heats up as well, with calls to rid the U.S. bulk-power system of bottlenecks. As the eternal optimist, I see large transmission projects showing signs of life and grid reliability improving. But not everyone is happy about that. […]

-

Coal

Global Monitor (September 2006)

Demand records fall nationwide;

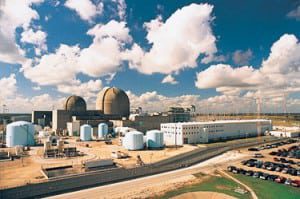

GE’s ABWR to be STP’s edge; Entergy buys Palisades plant; Dithering over desert disposal; Tourist trash-to-energy plant;

Brooklyn says "Yo!" to microturbines; POWER digest -

O&M

Focus on O&M (September 2006)

Level measurement in harsh environment;

Designing insulation for structures;

Shockingly clean boiler

Search