-

Business

POWER Digest (March 2009)

News items of interest to power industry professionals. RWE and E.ON to partner on new UK nuclear capacity. German giants RWE AG and E.ON AG on Jan. 14 said they would partner to develop new nuclear power stations in the UK. The 50:50 joint venture will have a long-term focus on seeking secure sites being […]

-

News

Vibratory Ash Extractor

The Vibratory Ash Extractor (VAX) recently unveiled by United Conveyor Corp. is designed to improve operational efficiencies for dry bottom ash – handling at plants whose operators want to transition away from wet systems. Suitable for pulverized bituminous and subbituminous coal boilers, the VAX can also be retrofitted for lignite-fired boilers. To minimize forced boiler […]

-

Legal & Regulatory

Generators Propose a Plan for Carbon Pricing

With the U.S. economy currently in a free fall, some utility industry leaders and elected officials argue that carbon cap legislation should be put on hold while the country recovers financially. However, President Barack Obama has a different game plan.

-

Coal

Polish Plant Beats the Odds to Become Model EU Generator

Once a Soviet satellite, Poland is now transforming into a thoroughly modern nation. To support its growing economy, this recent European Union member country is modernizing its power industry. Exemplifying the advances in the Polish electricity generation market is the 460-MW Patnów II Power Plant — the largest, most efficient (supercritical cycle), and environmentally cleanest lignite-fired unit in the country.

-

Water

Flue Gas Desulfurization Wastewater Treatment Primer

Purge water from a typical wet flue gas desulfurization system contains myriad chemical constituents and heavy metals whose mixture is determined by the fuel source and combustion products as well as the stack gas treatment process. A well-designed water treatment system can tolerate upstream fuel and sorbent variation over time and consists of multiple process treatment steps arranged in just the right order to produce wastewater acceptable for discharge.

-

Water

Oak Creek Power Plant Upgrades Cooling Water System

Formed suction intake designs have been used in many large vertical pump stations in flood control projects. Space limitations at the Oak Creek Power Plant Expansion Project near Milwaukee, Wisconsin, created a unique opportunity to apply this technology to an 800,000-gpm cooling water system upgrade for the entire Oak Creek Power Plant.

-

Hydro

What’s Damming Hydrokinetic Power in the U.S.?

Barely a month after the U.S. Federal Energy Regulatory Commission (FERC) licensed the nation’s first commercial hydrokinetic power station, Houston-based Hydro Green Energy in January completed installation of the first of two turbines at an existing run-of-river hydropower plant on the Mississippi River for the Minnesota city of Hastings. When the second turbine is installed later this spring, the two hydrokinetic turbines will constitute a floating array that will sit on top of a barge at the Army Corps of Engineers’ Lock & Dam No. 2.

-

O&M

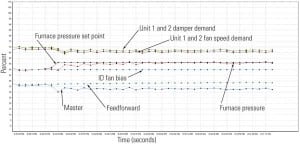

Boiler-Tuning Basics, Part I

Tuning power plant controls takes nerves of steel and an intimate knowledge of plant systems gained only by experience. Tuning controls also requires equal parts art and science, which probably is why there are so few tuning experts in the power industry. In Part I of a two-part series, we explore a mix of the theoretical and practical aspects of tuning boiler controls.

-

Waste to Energy

Power Generators Turn to Diverse Fuels

Like the airline industry, power generators all over the world have been seeking alternative fuels with which to produce electricity, and the blends are bound to get stranger. One company is looking to make liquid fuels from chicken fat, beef tallow, and pork lard, for example. Here’s a list of innovative fuels that generators could use in the near future.

-

O&M

"Blueprint" Your Pulverizer for Improved Performance

Pulverizer throughput is determined by the coal fineness desired for a given coal. However, compromising on coal fineness when your pulverizer isn’t up to snuff can increase NO x and cause many furnace problems. Your least costly option for increasing pulverizer capacity is to pay careful attention to key dimensions and critical tolerances during your next overhaul.

Search