Entergy Texas will seek approval for a 1.2-GW hydrogen and natural gas–fired combined cycle gas turbine (CCGT) power facility in Orange County, Texas.

The Beaumont-based Entergy Corp. subsidiary on July 29 announced it intends to file a Certificate for Convenience and Necessity with the Public Utility Commission of Texas “within the coming months” to build the Orange County Advanced Power Station. If approved, Entergy Texas will begin construction of the pioneering project in the second quarter of 2023 and plans to put it in service by summer 2026.

While the company said it will provide more details on specifics of the facility when it files its application with state regulators—including the gas turbine models it will utilize—it told POWER on Aug. 3 that the project should be capable of utilizing up to 30% of its fuel from hydrogen upon commercial operation. By adding hydrogen capability to the plant during construction, the company is effectively boosting the project’s flexibility to operate “well into the future—regardless of market or environmental changes,” the company said.

“Investing in hydrogen capabilities now will allow Orange County Advanced Power Station to use two fuels and more economically convert to 100% hydrogen in the future, as changing circumstances warrant,” it added. “This benefit is consistent with the nationwide movement toward a low-carbon economy and recognizes the investment communities and customers’ evolving demand for sustainability projects.”

A Large-Scale Distributed Generation Model

When completed, the Orange County project will dramatically ramp up Entergy Texas’s owned generation capacity, which currently stands at about 3 GW. The new project could also introduce a new fuel to its fleet.

In Texas, all its existing plants are gas-fired. They include the 933-MW gas-fired CCGT at Montgomery County Power Station in Willis; the 503-MW gas-fired Lewis Creek plant in Willis; the 151-MW gas-fired Hardin County plant in Kountze; and the 1.5-GW gas-fired Sabine plant in Orange County. Entergy Texas also holds minority ownership of the Big Cajun coal plant and the Nelson coal plant in Louisiana. All of Entergy Texas’s generating facilities (which provide power to 27 counties in Southeast Texas) are overseen by the Midcontinent Independent System Operator (MISO)—and fall outside the Electric Reliability Council of Texas (ERCOT) energy-only market, which dominates the rest of Texas.

As Sallie Rainer, president and CEO of Entergy Texas suggested on Friday, building a massive dual-fuel project to counter market turmoil would be beneficial for power-hungry Southeast Texas, which she said needs “reliable, low-cost and clean energy.” If built, the Orange County plant could “provide more than $1.5 billion in net benefits to customers by reducing reliance on energy markets,” she said. As an Entergy spokesperson told POWER, the company will also highlight the localized reliability benefits that the massive plant could offer to Southeast Texas in a “compelling case” that it is set to present to state regulators in the coming weeks.

In MISO, Entergy Texas sells energy produced by its generators into the market and then buys back from that market the amount of energy it needs to serve its customers, the spokesperson explained. “Our role as a company is to ensure we are continually working to provide our customers reliable, low cost and clean energy to power our region. Sound resource planning involves balancing generation resources that we own or have under contract with purchases from the MISO markets,” she said.

However, “While those markets generally offer low-cost energy and capacity and help achieve efficiency, they can be volatile—and prices can spike during times when supplies of energy and capacity are scarce,” the spokesperson added. “During these times, there can also be a shortage of local generation that can be delivered to customers in southeast Texas. By building new local generation, we protect our customers from the potential risks of volatile prices in both the capacity and energy markets.”

Still, Entergy Texas expects the Orange County project will be “the most efficient dispatchable generator in the market.” It “will produce significant amounts of energy to sell into the MISO market at a higher price than it costs to produce that energy at this modern facility. The margins from these sales flow directly to customers as an offset to their fuel charge. Further, the addition of a highly efficient generator to the market will lower the price of the energy purchased from the market to serve those same customers, which will also lower their fuel charge. Accordingly, customers savings will result from both margins made selling energy into the MISO market and from lowering the cost of purchases from that same market,” the spokesperson said.

Entergy has meanwhile also touted the project’s potential economic impact. A third-party economic impact analysis by TXP Inc. found that the construction and operation of the Orange County Advanced Power Station will play a “major role” in creating jobs and driving increased economic activity, the company said. “Estimates indicate that construction will provide more than 7,000 direct jobs in Texas and nearly $1.8 billion in economic activity for the regional economy. Once operational, the plant will provide approximately 27 permanent direct jobs in Texas,” it said.

A Major Investment in Hydrogen Optionality

But the project will also represent a concerted effort to steer the company—and its locality—toward long-term sustainability “in an economy where many stakeholders and customers are focused increasingly on decarbonization,” it noted. As POWER has reported, Entergy Texas’s parent Entergy Corp., an integrated energy company that owns a 30-GW power generating fleet, in September 2020 committed to achieving net-zero carbon emissions in 2050.

Efforts to achieve that goal so far include an ongoing integration of renewable energy resources, and continued investment in nuclear and more efficient gas generating units. Entergy has said, however, that longer-term sustainability will require evaluating and enhancing its portfolio transformation with emerging technologies, “such as distributed resources, alternative fuels like renewable natural gas and green hydrogen, carbon capture and sequestration, and advanced nuclear.”

Entergy kicked off its green hydrogen exploration last September by forging an alliance with power generation technology and equipment giant Mitsubishi Power. Under the partnership, the two companies suggested they were developing hydrogen-capable CCGT facilities and related infrastructure to enable hydrogen production, storage, and transportation. Entergy and Mitsubishi Power also said they would create “nuclear-supplied electrolysis facilities with energy storage,” as well as develop utility-scale battery storage systems.

The Orange County project, a self-build project, will be especially pivotal to making hydrogen co-firing “a reality,” as Entergy’s Chairman of the Board and CEO Leo Denault wrote in the company’s latest integrated report. “Additionally, we’re exploring the potential use of carbon capture and sequestration once that technology is economically available.”

Existing Hydrogen Infrastructure A Driving Factor

Entergy last year told POWER that while the project would begin operations capable of combusting a gas blend with 30% of hydrogen by volume, it planned to ultimately “finalize that design as well as designing the station for the eventual transition to 100% hydrogen-powered once hydrogen technology and infrastructure are established.”

That timeframe falls squarely within Mitsubishi Power’s development of a high-volume-capable hydrogen gas turbine. While the gas turbine manufacturer’s J-series model is already capable of combusting a mix of natural gas and up to 30% hydrogen by volume, it is targeting development of 100% hydrogen combustion technology by 2025. The gas turbine manufacturer has so far sealed similar deals—mostly for M501JAC units—with several other gas-fired power plants.

However, when asked whether the Orange County plant would use JAC units, Entergy Texas told POWER it would provide more details in the coming weeks. The company said, “Entergy, in collaboration with Mitsubishi Power, is developing opportunities for the use of additional hydrogen in power generation.”

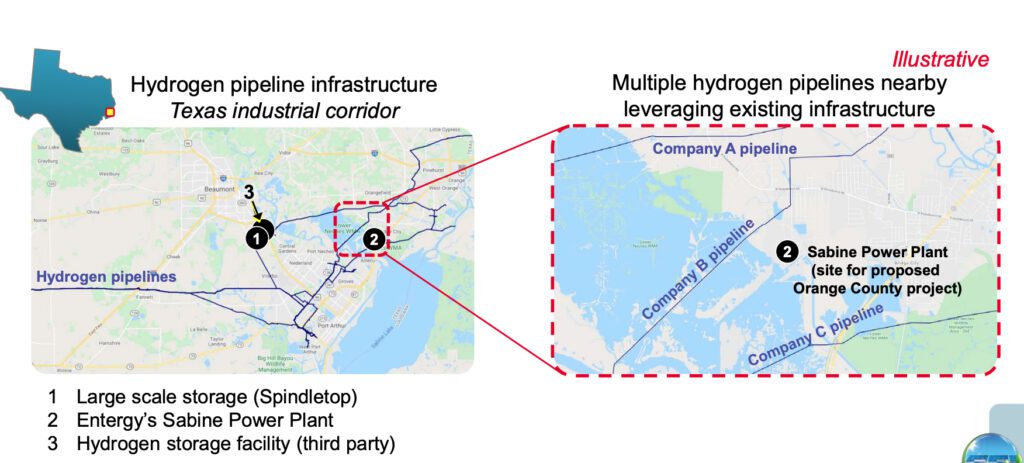

How much hydrogen the project will need to provide cost-effective, long-term reliability also remains uncertain. Entergy suggested the project may initially rely on existing infrastructure and hydrogen supply.

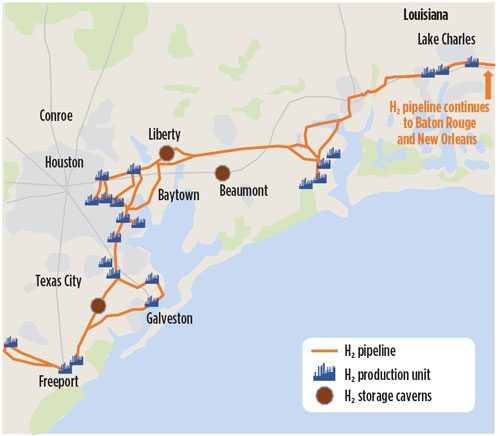

Hydrogen is already widely used in industrial processes, including by a number of Entergy Texas’s large industrial customers in Southeast Texas, an area characterized by petroleum refineries and chemical manufacturers, the company noted. In Beaumont, and nearby Houston and Freeport, 48 plants already extract hydrogen from natural gas, producing 3.6 metric tons of hydrogen a year for refineries and industrial plants, according to market analytics company Prescient & Strategic Intelligence.

The region also hosts an extensive network of at-scale salt cavern storage facilities and 900 miles of hydrogen pipelines—which represent “more than half of the U.S. [hydrogen] pipelines and one third of [hydrogen] pipelines globally,” said Andy Steinhubl, vice chair of the Board at the Center for Houston’s Future. If it leverages this existing infrastructure, the Orange County project could establish Southeast Texas “as a global hub for hydrogen production and consumption,” said Rainer.

Entergy said fuel for the Orange County plant “can be stored nearby in facilities such as in Entergy Texas’s Spindletop storage facility and can be deployed alongside natural gas to produce lower emissions energy reliably when needed, including working in hours when intermittent renewable resources do not generate power.” Entergy’s Spindletop gas storage facility in Beaumont, Texas, which is operated by PB Energy Storage Services, has three salt caverns with a reported working gas capacity of 6,606 million cubic feet. Entergy last year said it was evaluating an exploration to convert one cavern to hydrogen storage.

The project may also leverage Mitsubishi Power’s standardized hydrogen packages, Hydaptive and Hystore. As Mitsubishi Power company officials have told POWER, the Hystore package was inspired by ongoing projects to outfit the 840-MW Intermountain Power Project (IPP) in Millard County, Utah, with hydrogen-capable turbines, as well as the company’s massive Advanced Clean Energy Storage (ACES) project, a salt cavern project that promises to store up to 1 GW of renewable energy as hydrogen gas (and is strategically located near the new IPP facility). The Hydaptive package is focused on site integration, spanning the electrolyzers to the gas turbines.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine)

Updated (Aug. 3): Added technology and market details related to the Orange County project.