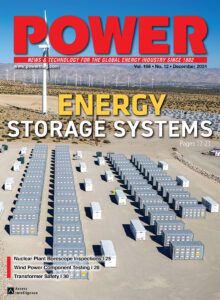

Flammable insulating fluids and electrical faults pose significant fire and explosion risks to transformers. These hazards can result in catastrophic damage, disrupt business continuity, and cause extensive collateral damage to surrounding equipment and infrastructure. This article provides real-world case studies demonstrating fire barrier effectiveness in mitigating fire and explosion risks, protecting critical infrastructure, and minimizing operational disruptions and financial losses.

Substations and electrical switchyards are vital nodes within the power grid, facilitating electricity conversion from high-voltage transmission lines to lower-voltage distribution networks. Transformers, the cornerstone of these facilities, are highly susceptible to explosion and fire hazards due to high-energy electrical environments and flammable insulating materials, such as oil. Environmental factors, such as lightning strikes or equipment failure, can further escalate the risks of explosions and fires. Thus, implementing robust protection measures is not just necessary—it is critical.

The ramifications of an explosion and fire within a switchyard (Figure 1) are profound. Human safety is paramount, as fires can pose immediate life-threatening dangers to onsite personnel. In addition to endangering lives, transformer fires often result in extended power outages, disrupting essential services and compromising grid stability. The financial costs associated with these incidents are multifaceted, encompassing direct expenses such as equipment replacement and infrastructure repairs and indirect costs like loss of operational capacity, potential legal liabilities, and damage to a company’s reputation. A preventable fire incident could lead to a loss of customer confidence, especially if the outage is prolonged or recurring.

|

|

1. Fire barriers ensure compliance with regulatory fire safety standards, safeguarding switchyards from the economic and operational risks associated with transformer fires. Courtesy: Fire Barrier Experts |

Given the severe consequences, fire protection in switchyards must be treated as both a regulatory and strategic priority. Explosion and fire barriers are a vital component of these safety systems. By physically containing fires, these barriers help protect adjacent equipment and minimize the spread of heat and smoke, ensuring the continuity of grid operations. They effectively confine fires and explosions to a limited area, which helps reduce damage, protect workers, and enable quicker response times from fire suppression teams. Moreover, fire barriers help utilities comply with rigorous safety regulations, avoiding costly penalties, lawsuits, and reputational harm.

Understanding Transformer Explosion and Fire Hazards

Transformer explosions and fires typically result from a combination of mechanical, electrical, and environmental factors. Electrical faults are one of the most common causes, stemming from insulation failures, short circuits, or arcing within the transformer. These faults can generate significant heat, leading to the ignition of the insulating oil used in transformers.

Other mechanical failures, such as leaks or ruptures in the transformer casing, can cause flammable materials to be exposed to ignition sources. Environmental factors like lightning strikes, wildlife interference, and severe weather conditions can exacerbate these risks by causing electrical surges or physical damage to the transformer. Additionally, aging transformers are more vulnerable to internal failures due to the degradation of insulation and other materials over time. Contaminants, like moisture or particulates, further heighten the risk of failure, creating a more volatile environment inside the transformer.

Intentional acts of disruption against substations, motivated by vandalism, sabotage, or acts of terrorism, are on the rise. In one of the most significant incidents of intentional damage, snipers attacked the Metcalf transmission substation near San Jose, California, in 2013. The attackers fired at 17 transformers, causing them to leak oil and overheat, which led to substantial damage. A similar sniper attack on two Moore County, North Carolina, substations in 2022 resulted in power outages for tens of thousands of residents.

The impact of transformer fires extends well beyond the immediate loss of equipment. A transformer fire can compromise the overall functionality of an electrical switchyard, resulting in power outages that disrupt the electricity supply to homes, businesses, and essential services. A single transformer failure could lead to cascading failures within the broader grid, further amplifying the outage’s scope and duration. Damaged transformers often require extensive repairs or complete equipment replacement, adding to the recovery time.

The purchase lead times for utility-scale transformers, including those used in switchyards, have significantly increased in recent years due to global supply chain disruptions, rising demand from grid modernization projects, and the integration of renewable energy sources. Lead times for these transformers typically range from 12 to 24 months, but in some cases, they can extend even longer, particularly for custom-built units. Supply chain shortages for critical materials like steel and copper further exacerbate these delays.

Protecting Critical Infrastructure

Fire barriers are physical structures or materials strategically installed to contain and isolate fires in electrical switchyards, particularly around high-risk equipment like transformers. Their primary purpose is to limit fire spread, protect adjacent equipment, and minimize damage. In a switchyard, where high-voltage transformers and other sensitive infrastructure are present, fire barriers are crucial for ensuring the safety of the facility. They act as a passive explosion and fire protection system, slowing down or preventing the spread of flames, heat, and smoke, giving operators and firefighters more time to respond to incidents.

In electrical switchyards, the most critical assets requiring protection are transformers, control buildings, circuit breakers, and other high-voltage equipment essential for power distribution. Transformers, in particular, are vulnerable due to the presence of flammable insulating oil and their constant exposure to high-energy electrical environments. Fire barriers protect these vital assets from not only fire and heat but also from potential explosions and collateral damage caused by the failure of adjacent equipment.

Switchyards often contain multiple transformers in a bank and equipment nearby, so a fire in one transformer could quickly spread to others. Fire barriers help prevent a cascading failure, which could lead to widespread power outages. Additionally, fire barriers can help protect against environmental hazards, such as wind-blown debris or the exposure of flammable fluids to fire, further reducing the likelihood of an escalating disaster.

Fire barriers in switchyards can generally be classified as passive protection. Still, they must guard transformers from explosions, shrapnel, and flaming liquids, and contain the event, becoming active as a defense system.

Transformer Fire Barriers

Transformer fire barriers are freestanding structures designed as physical barriers. They provide a physical separation to protect nearby assets if a failure occurs. Once installed, these barriers do not require any activation or external input to function. They protect from day one with little or no maintenance costs. They are intended to slow or stop the spread of fire, heat, and smoke, providing containment and sufficient time for a safe emergency response.

A passive fire barrier offers several critical advantages when protecting electrical infrastructure, especially in transformer-heavy environments like electrical switchyards. These barriers serve as a first line of defense, ensuring that explosions and fires are contained and mitigated, even without active intervention. The following are some key advantages of implementing passive fire barriers.

Continuous Protection. One of the most significant advantages of a passive fire barrier is that it provides constant, non-stop protection. Unlike active fire protection systems that require sensors, alarms, or activation (such as sprinklers or foam systems), passive fire barriers work continuously from the moment they are installed. Their function is automatic and does not rely on mechanical or electrical activation, making them exceptionally reliable in critical infrastructure scenarios where operational interruptions or failures can occur. This continuous protection ensures that even if other fire suppression systems fail to activate or there is a delay in response time, the passive barrier is still working to limit fire spread, buying valuable time for emergency responders.

Containment of Fire Spread. The primary function of passive fire barriers is to contain the spread of fire, explosion, heat, and smoke to a localized area. In electrical switchyards, where transformers are often positioned near one another, preventing fire spread is essential. A fire in one transformer can quickly escalate and damage adjacent transformers, circuit breakers, or control buildings, causing widespread outages and equipment failure. By confining the fire to a single area, passive barriers minimize the risk of cascading failures, reducing the overall damage to critical infrastructure. This containment also helps prevent the triggering of secondary fires, which can occur when flammable materials in nearby equipment are exposed to heat and flames.

Low Maintenance and Operational Costs. Once installed, passive fire barriers require minimal maintenance. Unlike active fire suppression systems, which need regular testing, inspections, and occasional repairs, passive barriers generally have a long service life with low ongoing costs. Materials such as fire-rated walls, intumescent coatings, or fireproof enclosures are designed to withstand harsh environments, providing durable protection over time.

This low maintenance requirement translates into lower operational costs for utility companies. Active systems may incur expenses related to mechanical or electrical failures, requiring frequent inspections to ensure they are in working condition. On the other hand, passive barriers are static and dependable, making them cost-effective over a facility’s lifespan.

Enhanced Safety for Personnel. In addition to protecting equipment, passive explosion and fire barriers improve personnel safety, particularly for onsite maintenance workers. Control buildings are usually located within 50 feet of transformers requiring fire barriers. By containing a fire to a specific area and reducing the spread of heat and smoke, passive barriers provide additional time for evacuation and emergency response. This extra time can be critical in avoiding serious injuries or fatalities.

Compliance with Regulatory Standards. Another advantage of passive fire barriers is that they help utilities meet regulatory and industry safety standards. Regulatory bodies, such as the National Fire Protection Association (NFPA), the Institute of Electrical and Electronics Engineers (IEEE), and the Federal Energy Regulatory Commission (FERC), outline stringent guidelines for fire protection in high-risk environments like switchyards. Fire barriers play a vital role in ensuring compliance with these regulations.

Durability and Environmental Resistance. Transformer fire barriers are typically constructed from materials resistant to fire and built to handle explosion, shrapnel, flaming liquids, and environmental factors such as moisture, extreme temperatures, and weather conditions. For example, galvanized steel and fire-rated assembly panels and construction are built to withstand long-term exposure to outdoor elements while maintaining their protective capabilities.

Replace Active Fire Protection Systems. Sprinkler systems are outdated and create an environmental risk when deployed at switchyards, especially near waterways. Foam suppression systems are designed to engage and suppress fires actively. Still, they have been outlawed for use as they introduce known carcinogens into the fire and are no longer accepted because of the health and safety risks. Both systems require significant investment in continuous maintenance.

While existing passive and active fire protection systems are valuable, passive fire barriers serve as the first line of defense, providing reliable containment even when active systems fail, are delayed, or are removed for compliance reasons. The passive barrier contains and isolates a fire, and includes compliance with applicable regulations.

Fire Barrier Design Considerations

Several strategic and practical factors must be considered when designing and implementing explosion and fire barriers for transformer protection in electrical switchyards. The design process includes identifying hazards, distances, wind loads, seismic requirements, elevations, foundations, and line-of-sight considerations. These considerations ensure the barriers effectively contain fires and integrate seamlessly into a facility’s overall infrastructure. Proper planning can mitigate the risks associated with transformer fires, reduce downtime, and enhance operational resilience (Figure 2).

|

|

2. This series of photos illustrates an improperly designed block and concrete fire barrier. Courtesy: Fire Barrier Experts |

Designers must consider several key design factors to ensure fire barriers provide maximum protection. One of the primary considerations is the 50-foot rule, which refers to the recommended minimum distance between transformers, control buildings, and critical equipment to prevent damage from fire and explosion. Fire barriers should be placed to isolate equipment while maintaining this safety distance wherever possible. When space constraints make the 50-foot rule challenging, fire barriers act as a crucial mitigation measure by compensating for closer proximity.

The height and thickness of fire barriers are also essential to their effectiveness. Barriers must be tall enough to contain fire, smoke, and heat within the immediate area of the transformer, preventing them from reaching adjacent transformers or critical components. Additionally, fire barriers should be designed to withstand wind loads, seismic activity, and other environmental stresses that may occur in the area, ensuring that they remain structurally sound in an emergency.

Fire barriers must be designed to withstand these additional risks in regions prone to wildfires, floods, or other natural disasters. Fire barriers in wildfire-prone areas, for example, may require heat-reflective coatings or extra reinforcement to prevent the external spread of fire. Environmental considerations should also be factored into the design, such as protecting nearby water sources from contamination by fire suppressant chemicals.

By carefully considering these design and strategic elements, utilities can ensure that their fire barrier systems provide reliable and long-term protection for critical electrical infrastructure. Proper planning and material selection can significantly reduce the risks associated with transformer fires and minimize operational disruptions.

Case Studies and Practical Applications

Key lessons highlight the importance of fire barriers and other protective measures in mitigating transformer fire hazards. Some examples follow.

Hydro Dam Waterway Project. This project highlights how fire barriers can be effectively installed to protect critical transformer-to-transformer assets near water bodies. The key takeaway was the critical importance of proper barrier placement in areas vulnerable to environmental risks, such as flooding or water damage, which can significantly exacerbate fire incidents. Barriers in this setting will contain fire and prevent contamination from spreading to nearby water resources (Figure 3).

|

|

3. Deluge sprinkler systems around waterways have been shut down and removed because of the environmental issues associated with an unplanned release or even their use in an event. This series of images shows systems that were brought into compliance with fire barriers designed to fit in tight spaces to provide the required separation. Courtesy: Fire Barrier Experts |

Critical Substation-to-Control Building Project. In this project, fire barriers were strategically placed to protect a substation near an adjacent building. The lesson from this project was the effectiveness of fire barriers in preventing collateral damage to nearby structures. Without barriers, fire spread could have easily caused the loss of transformer assets and the adjacent building, extending downtime and repair costs. These applications highlight the need for barriers in mixed-use environments where electrical infrastructure is near other facilities (Figure 4).

|

|

4. Fire barriers are also effective in preventing the spread of fires to nearby transformers and infrastructure, especially when equipment is positioned in close proximity as shown in this series of images. Courtesy: Fire Barrier Experts |

Transformer-to-Transformer Protection. A project at a major California utility demonstrated the need for adequate separation between transformers. When a fire occurred, the installed barriers successfully confined the fire to a single transformer, preventing it from spreading to adjacent transformers and reducing the overall damage. The key takeaway was that barriers are essential for limiting fire spread, especially when transformers are positioned nearby (Figure 5).

|

|

5. Fire barriers were retrofitted at a substation owned by a major West Coast utility. Note the inadequate spacing between the transformers (left). A fire barrier in a “T” configuration designed to withstand fire and explosion was placed between transformers and the control house at another site (right). Courtesy: Fire Barrier Experts |

Successfully implementing fire barriers in electrical switchyards requires a careful and coordinated approach that addresses various technical, regulatory, and operational considerations. Following best practices during planning, installation, and ongoing maintenance ensures fire barriers provide effective protection and meet all safety standards.

The first step in implementing fire barriers is conducting a comprehensive risk assessment of the switchyard. A risk assessment involves identifying critical assets, evaluating potential fire hazards, and determining the most effective locations for fire barriers. The evaluation should also include factors such as transformer proximity, fire loads, environmental conditions, and potential collateral damage.

Once the risk assessment is complete, a detailed design plan should be developed. This plan should specify the fire barrier’s materials, dimensions, and placement, ensuring they align with industry regulations and safety standards. Early collaboration with engineers, safety professionals, and regulatory bodies ensures the design meets operational and compliance requirements.

Risk Mitigation Is Important

The explosion and fire hazard risks associated with individual transformers are often unique. Fire barriers can play a critical role in reducing or even eliminating some fire hazard risks. However, strategic considerations are necessary for effective implementation.

Whether installed in new or existing facilities, explosion and fire barriers provide a reliable and cost-effective solution for preventing fires from spreading to adjacent transformers and equipment, minimizing or eliminating collateral damage. These barriers help mitigate the immediate risks associated with transformer fires and protect utility companies from the financial and reputational damage that can arise from prolonged outages or incidents. By taking a forward-thinking approach to fire safety using separation and containment, utilities can minimize the impact of transformer fires, protect their critical assets, and maintain the trust of their customers and stakeholders.

—John Sinisi is subject matter expert, and Montgomery Sinisi is vice president of Operations and Assessments with Sinisi Solutions LLC.