Siemens Energy is teaming with UK power giant SSE to develop a combustion system that will allow its flagship SGT5-9000HL gas turbine to run 100% on hydrogen while maintaining the flexibility to operate with natural gas and blends of the two.

The two companies on Dec. 9 launched “Mission H2 Power,” a project that will support the decarbonization of SSE’s 849.45-MW Keadby 2 Power Station in North Lincolnshire, which began operations in March 2023. The power plant, whose efficiency of 64.18% was verified by the Guinness World Records in May 2024, holds the title for the most powerful combined cycle power plant and the most efficient combined cycle power plant.

The “multi-million-pound co-investment” under Mission H2 Power announced on Monday responds to several urgent and timely factors. While the UK is committed to reaching net zero by 2050 and decarbonizing its power sector by 2030, it acknowledges that it will need dispatchable low-carbon power as it makes the transition. In March, the UK committed to supporting the building of new gas power stations, including unabated gas generation at least into the 2030s, as a “backup to ensure energy security and reduce costs has been recognized by the Climate Change Committee.”

According to the National Energy System Operator (NESO)—a government organization that officially launched on Oct. 1 to provide an independent and holistic approach to the UK’s challenges—all current net-zero pathways indicate a role for natural gas in industry and power generation, including through the adoption of carbon capture and storage (CCS) or a shift to hydrogen.

Last year, however, the Department for Energy Security and Net Zero (DESNZ) suggested the shift to hydrogen was becoming more pertinent, citing stakeholders that said hydrogen-to-power (H2P) could respond more flexibly than power CCS. “Some stakeholders also see a role for H2P in providing zero carbon baseload generation. Ultimately, the future role for hydrogen will depend upon a number of factors, including but not limited to the future generation mix and the amount of renewable, extent of [demand-side response], and deployment of storage and interconnection in the electricity system,” its report noted.

NESO’s November 2024–released Clean Power 2030, meanwhile, envisions that gas power’s share could fall from about 33% in 2023 to less than 5% in 2030 if demand flexibility ramps up, though it suggests around “35 GW of unabated gas (broadly consistent with the size of the existing fleet) will need to remain on standby for security of supply.”

Meanwhile, it suggests up to 2.7 GW of hydrogen to power and gas CCS could be feasibly built in the country by 2030, although these sources could provide just 0% to 3% of its 2030 supply. For now, “Large-scale hydrogen storage appears unlikely before 2030, and relative costs for hydrogen and gas with CCS are uncertain,” the report notes. “Contracting arrangements should be developed with the expectation that these plants operate flexibly, rather than operating continuously. More will be needed beyond 2030 and will be advantageous if delivered earlier, potentially enabling a lower cost 2030 system that takes pressure off other delivery challenges,” it says.

A Future-Looking Investment

According to SSE, investment in Mission H2 Power underlines the power company’s “commitment to transition away from the use of unabated fossil fuels in electricity generation and accelerate hydrogen projects which can support the delivery of a clean power system by 2030 alongside the wider decarbonization of industry.”

“It isn’t enough for developers to simply talk about an ambition to transition from gas to hydrogen—delivering a clean power system requires bold action which is why we’re entering into this collaboration with Siemens Energy, a long-standing partner of SSE,” said Finlay McCutcheon, SSE Thermal managing director. “We know hydrogen-fired power stations will be an essential element of the energy mix in a net zero world and Mission H2 Power will help us accelerate their deployment through engineering excellence.”

McCutcheon noted SSE is already heavily invested in hydrogen projects across the value chain, including both blue and green hydrogen production, and large-scale hydrogen storage. “Our projects will be pivotal in providing flexible backup to renewables and while we still need to see a rapid acceleration in policy and deployment, the need for this technology is beyond question—it is a matter of when not if and this partnership can help us reach that destination as soon as possible,” he said.

As part of its hydrogen-to-power portfolio, SSE is notably developing the Keadby Next Generation Power Station with partner Equinor in the vicinity of the Keadby Power Station in North Lincolnshire—a site that currently hosts the 1996-built 732-MW Keadby 1 and the highly-flexible 849.45-MW Keadby 2 CCGT project. The Keadby Next Generation Power Station is expected to comprise “one high CCGT unit and associated infrastructure,” but it will be designed from the outset to run 100% on hydrogen, natural gas, or blends.

In tandem, SSE developing the 913-MW Keadby 3 CCS Power Station at the site, a gas-fired plant that will be equipped with CCS. “By obtaining consents for both low carbon CCGT technology options (i.e. CCS-enabled in the form of Keadby 3 and hydrogen-fired in the form of [the Keadby Next Generation Power Station] on the site, SSE can continue to support the UK’s security of supply in accordance with government policy, and be ready to develop a low carbon CCGT as soon as a commercial decision can be made based on market certainty around the availability of either a CO2 pipeline or a hydrogen supply,” the company said in a recent filing.

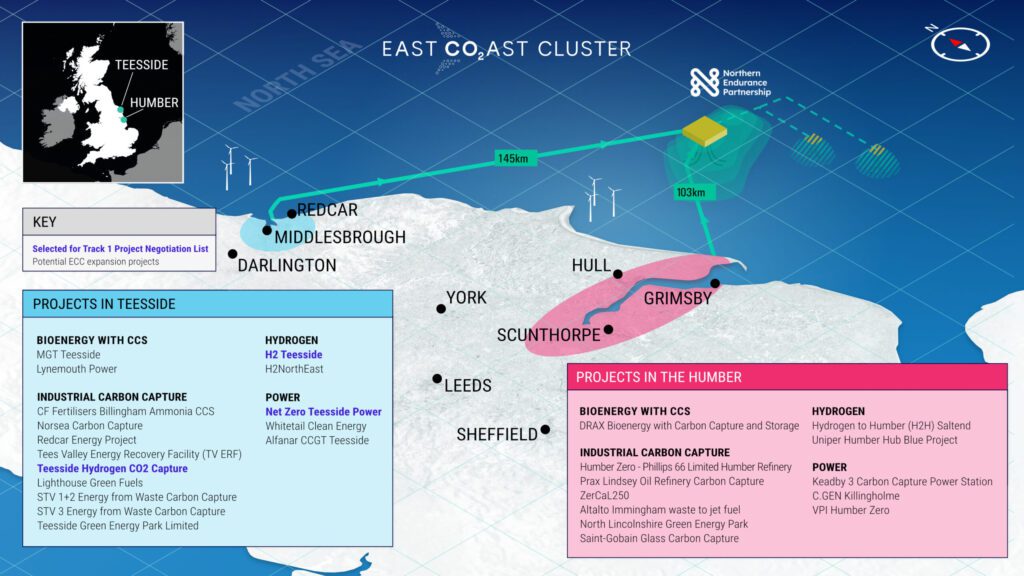

SSE said the Keadby site’s location within the East Coast Cluster—a collaboration between Zero Carbon Humber, Net Zero Teesside, and the Northern Endurance Partnership—adds to Mission H2 Power’s strategic importance. The East Coast Cluster (ECC) in Northeast England, a significant UK initiative aimed at decarbonizing the UK’s Humber and Teesside industrial regions, is expected to start construction in mid-2025. Earlier this week, notably, the Northern Endurance Partnership (NEP) and Net Zero Teesside Power (NZT Power) announced financial close for two major CCS projects at Teeside, including for NZT Power, an 860-MW gas-fired integrated project (featuring a GE Vernova gas turbine) that could become one of the world’s first commercial-scale gas-fired power stations equipped with carbon capture when it begins operation in 2027.

Major Boost to Siemens Energy’s 100% Hydrogen Gas Power Strategy

For Siemens Energy, the prospect of showcasing an effective combustion technology that can flexibly operate on 100% hydrogen for its flagship SGT5-9000HL gas turbine marks a major boost.

As Siemens Energy experts have told POWER, the company began the development of the 9000HL—its largest, most powerful, and most efficient heavy-duty gas turbine model—around eight years ago, with the goal of creating a high-performance engine to compete in the J-class market. But, rather than taking a revolutionary approach, the company leveraged its extensive experience, drawing on millions of operating hours with proven H-class and E-class engine architectures. The evolutionary step sought to enhance performance and efficiency compared to Siemens Energy’s previous 8000H model.

A key part of the 9000HL’s development has involved a rigorous testing and validation process. Siemens Energy has utilized a dedicated rig testing facility outside of Berlin to thoroughly evaluate the combustion system, pushing it beyond the expected operating range to ensure reliability. The upfront testing helped the company deliver a series of notable “firsts” in quick succession, experts noted.

In April 2020, the company marked first fire of a 60-Hz SGT6-9000HL gas turbine at Duke Energy’s Lincoln Combustion Turbine Station in North Carolina. The 411-MW SGT6-9000HL, installed in April 2020 at the greenfield simple-cycle gas power plant, continues validation testing as Duke Energy utilizes the facility for peaking power needs. In August 2022, notably, the Duke Energy project received two Guinness World Records for the highest power output of a simple-cycle unit and the highest ramp rate—more than 100 MW/minute.

Keadby 2’s 593-MW SGT5-9000HL, its first 50-Hz 9000HL, marked first fire just weeks later, in May 2020. “Serial number two” for the 60-Hz 9000HL began commercial operation in March 2023 (weeks after Keadby 2 marked completion) at Cooperative Energy’s R.D. Morrow Sr. Generating Station in Mississippi. That project marked the first baseload deployment of 9000HL technology and its deployment at a brownfield site. (The Morrow project won POWER’s prestigious Reinvention Award in 2024 for its repowering significance and Cooperative’s in-house execution of the complex project.)

Siemens Energy, which rolled out a roadmap to deliver 100% hydrogen-capable gas turbines in 2020, has also marked a succession of developmental milestones. In 2023, it celebrated the successful test of an SGT-400, an industrial gas turbine powered by 100% green hydrogen, as part of the HYFLEXPOWER combined heat and power (CHP) project in France. Siemens Energy supplied the electrolyzer for the project and developed the dry low emissions (DLE) combustion technology for the SGT400 gas turbine. Last year, it also successfully conducted a blending test at Constellation’s 753-MW Hillabee Generating Station in Alabama that showed the plant’s Siemens Energy’s SGT6-6000G heavy-duty gas turbine could safely operate on a blend of 38% hydrogen, marking a record.

The latest SGT5/6-9000HL gas turbines incorporate the Advanced Combustion for Efficiency (ACE) system, which enable them to achieve combustion of up to 50% hydrogen by volume, Siemens Energy has noted. The advanced can-annular combustion system notably features 25 premix burners, which improve fuel and oxygen mixing, while also enabling gas turbine turn-down to 30% minimum environmental load.

By 2030, large gas turbine DLE systems are targeted to be capable of running on 100% hydrogen. The company has noted it would employ several key technology enablers to get the complex systems to 100%, including high fidelity computational fluid dynamics, which enables a clearer picture of the flame structure, additive manufacturing, to include new materials for advanced premixed combustion swirlers, and high-pressure combustion testing.

The Mission H2 Power collaboration, notably, will see “additional facilities constructed at Siemens Energy’s Clean Energy Centre in Berlin to allow testing of the technology for large gas turbines to take place,” SSE said on Monday.

“We’re delighted to be building on our existing partnership with SSE and developing plans to help kickstart the zero-carbon hydrogen economy,” said Darren Davidson, Vice President of Siemens Energy UK&I. “The UK Government wants to deliver clean power by 2030, and hydrogen can be an important part of that energy mix. We recently welcomed UK Prime Minister Sir Keir Starmer to our Siemens Energy site in Berlin. This partnership is a great example of how we can share knowledge and work together to deliver on energy security,” he said.

Davidson stressed the strategic advantage of collaboration with industry. “We are living in a transformative time for the energy sector,” he said. “This new collaboration is a significant step in reaching the point where large gas turbines can run on 100% hydrogen.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).