Refractory has always been an integral part on any steam-generating boiler. Refractory materials are used for filling gaps and openings to keep the fire inside the furnace, lining ash hoppers (wet and dry) for collecting ash and slag, and for the protection of lower furnace wall tubes inside fluidized bed, cyclone-fired, or refuse-derived-fired boilers.

Refractory failure is a very common problem experienced by operators of power boilers, and failures have a direct effect upon the amount of fuel consumed by the steam generator. Compared with most components found in the steam-generating industry, the cost of the refractory and its installation are very small. Yet, if it is improperly manufactured, specified, stored, mixed, installed, cured, or dried, refractory will have an adverse effect upon energy usage and operation.

Refractory experts estimate that refractory-when properly specified, manufactured, stored, mixed, installed, cured, or dried-will save as much as 5% to 7% annually in fuel cost for the typical utility boiler (Figure 1).

1. Typical refractory failure inside a steam generator caused by improper installation. Source: Gary Bases

Often, slag and ash formation on the refractory can reduce furnace heat absorption, raise exit gas temperatures, increase attemperator spray-flow temperature, and interfere with ash removal or equipment operation.

Slag is the formation of molten ash that is either partially fused or re-solidified ash deposits (ash fusion) that is formed based on the ash temperature and composition. In order for slag to adhere to a surface and form deposits, the ash particles must have a viscosity low enough to wet the surface. If iron is present, it will raise all four values of ash fusion temperatures (initial deformation, softening, hemispherical, and fluid). The greater the iron-content found in the ash, the greater the difference in ash fusibility between the oxidizing and the reducing condition.

Coal ash, the residual product that is left over after burning of the fuel, has a low fusion temperature and can react with iron oxides and form large carbon deposits in the refractory material. These large deposits can eventually cause a spall (loss of fragments or pieces) from the refractory surface.

Find the Root Cause of the Failure

Discovering why a refractory material fails is a complex problem because failure is not caused by just one factor but usually by a combination of the following factors:

- The material selected does not match the environment that exists (the reducing atmosphere).

- The material selected does not match the fuel being burned (in terms of the amount of alkali, sulfur, hydrocarbons, vanadium, or moisture that is present in the fuel).

- The material was improperly stored, mixed, installed, cured, and/or dried.

- The material selected did not match the environment created after the burning of the fuel (one of ash and slag).

To identify the root cause of a refractory failure, the five-step process outlined below should be closely followed while paying attention to the amplifying comments and suggested best practices.

Step 1: Begin the Discovery Process

Collect and document some basic information on the plant and the failure. In many cases the discovery process requires interviews with plant and installation personnel. These folks often know firsthand about the history of the refractory in question. Next, the following information should be identified and documented:

- Obtain material samples and data sheets describing the existing brick or refractory lining.

- Collect material samples of the ash clinkers and slag and send the samples to a laboratory for chemical analysis.

- Determine where and for how long the refractory was stored prior to installation. Also obtain the manufacturing date of the refractory material.

- Determine the ambient condition at the time of the installation.

- Establish how much material was installed and how it was installed or applied (pneumatically, toweled, poured, shotcrete, etc). Also, find out how the material was cured and/or dried and what procedures were followed.

Step 2: Examine the Existing Material and Test

The existing material (or the lack thereof) should be examined for signs that may indicate the root cause of the failure. When looking at an existing refractory lining or photos of the existing lining, keep these questions in mind:

- Did the material fail due to thermal shock, usually indicated by large sections of the top surface being sheared away (Figure 2)?

- Is there any evidence that the materials had been exposed to excessive temperatures (such as excessive shrinkage or glazing)?

- Is there any evidence of mechanical abuse (broken and jagged edges or holes)?

- Did the material fail due to the operation of the equipment, furnace, or boiler?

- Was the refractory material installed improperly (does it have a porous or popcorn-like texture)?

2. A typical slag sample from a coal-fired steam generator. Courtesy: Gary Bases

Samples of the existing refractory material should be gathered and sent out for a cold crush test. This test will verify the strength of the installed material. The results can then be compared with the manufacturer’s material data sheets. If the strength of the existing installed material is low, the mix probably was too wet when installed.

Samples of the existing slag and ash clinkers should also be gathered and sent out for chemical analysis. The slag samples should also have a PCE (pyrometric cone equivalent) test performed to verify the minimum temperature that the refractory may have been exposed to.

Step 3: Calculate the Base-to-Acid Ratio

The next step is to document the environment that the refractory material was exposed to. One way to do this is by calculating the base-to-acid ratio (B/A, values taken from the information received from the chemical analysis test mentioned in Step 2). This B/A ratio will give an indication of what type of refractory material should have been chosen in the first place.

Here is one way to calculate the base to acid ratio, based on the mass fractions of the following compounds, determined by the laboratory data results:

B = Fe2O2 + CaO +Na2O + P2O5 + MgO + ZnO + MnO

A = SiO2 + Al2O3 + TiO2

A base-to-acid ratio less than or equal to 0.25 indicates an acid condition. An acid condition would indicate that a SiO2 type refractory should have been used.

A base to acid ratio greater than 0.25 but less than 0.75 indicates a neutral condition. A neutral condition would indicate that an Al2O3, SiC, or chrome-type refractory material should have been used.

A base to acid ratio greater than or equal to 0.75 indicates a basic condition. A basic condition would indicate that an MgO, or a Dolomite-type refractory material should have been used.

Step 4: Review the Collected Data

Now it is time to analyze all the information gathered in Steps 1 and 2. All of the service conditions must be reviewed and analyzed thoroughly in order to see how they could affect the installed/failed material. This includes the fuel or raw materials being burned, the startup fuel that was used, the ash and slag content, gas temperatures, and the plant operations and procedures.

This information can provide much insight into refractory failure modes. For example, the moisture content in the fuel can affect the refractory material. High moisture content, or the combined moisture content in the fuel with a reducing atmosphere, can cause a separation of silicon carbide base materials (grain). This separation can occur when the total percentage of the moisture content found in the fuel is greater than 15% or when the combined total percentage of the moisture content in the coal and the reducing atmosphere percentage is greater than 15%.

Also, certain amounts of chemicals (iron oxide, potassium, or sulfur) found in the fuel, slag, or ash could react with cements (calcium-aluminate) that are present in a cement-bonded type of refractory, especially if a reducing atmosphere was present.

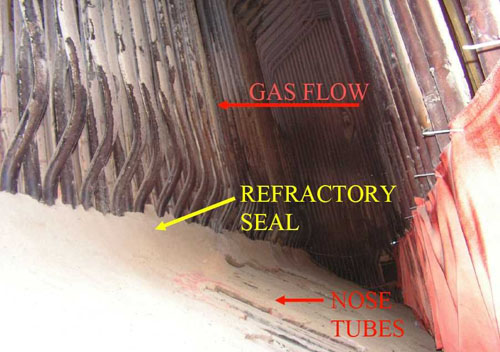

In some plants, liquid startup fuel may contain vanadium. Vanadium could react with the silica and lime in the cement that is found in a cement-bonded type refractory. When vanadium is present, it can cause a chemical attack and surface failure or cause a complete refractory failure. Figures 3 through 5 illustrate furnace regions were refractory was missing during an inspection.

3. A superheater box where the refractory is missing, viewed from above. Courtesy: Gary Bases

4. The refractory seals inside this furnace failed and must be replaced. Courtesy: Gary Bases

5. Another view of refractory seals that must be replaced. Courtesy: Gary Bases

Step 5: Review the Installation Procedures

Assuming the right refractory material was selected for the given boiler, the next step is to review and determine if the proper installation procedures were used. A number of installation factors can prevent a refractory material from reaching its proper strength. A refractory material that is unable to reach its designed strength has the highest potential for failure (Figure 6). Consider asking the following questions.

6. The four typical methods for repairing refractory are (top to bottom) "gunning," shotcrete, pouring, and troweling. Courtesy: Gary Bases

Was the material fresh, and were the proper storage procedures followed? Refractory material should have been manufactured in the proper time period based on the installation date and manufacture date. One year is recommended for a cement-bonded material used for conventional seals inside boilers and three months or less for materials used in high-temperature and abrasion areas, such as are found inside fluidized bed boilers, cyclone-fired boilers, or wet bottom ash hoppers. Refractory material should always be stored in dry, well-ventilated conditions. Use fresh refractory materials and follow proper storage procedures to ensure that the refractory will not lose strength.

Was the proper water used for mixing? Many common industrial compounds can easily contaminate a refractory mix and seriously affect its strength. Certain salts can react with the refractory cement to make the material almost useless. Most refractory manufacturers recommend using potable water (suitable for drinking) for mixing. The use of the wrong type of water (for example, river water) will hinder the ability of the refractory material to reach its proper strength.

Was the right installation equipment used and the recommended pot life followed? Using the right type of mixer, following proper mixing procedures, and staying within recommended pot life are other important installation factors. Using the wrong mixer or pneumatic gun could also affect the strength of the refractory material. For example, many pneumatically applied refractory materials require the material to be pre-wetted prior to the actual mixing and installation. If the installing contractor had used a continuous-feed mixer (which adds dry material into a hopper and adds water only at the nozzle), the material could not be pre-wetted due to the nature or characteristics of a continuous-feed mixer. This could reduce the strength of the installed material.

Also, every refractory material has a "pot life," which designates how long a mixed refractory material can be used after mixing. Failing to follow recommended pot life can result in a refractory material not reaching its proper strength. If the pneumatic installation of the refractory is interrupted for a period of time longer than the recommended pot life, then the material found in the mixer and hoses should be discarded and not re-used.

Was the refractory installed during the recommended ambient conditions? In cold or hot weather the strength of a refractory material could be adversely affected. Most refractory manufactures recommend that the final mix temperature be in a specific range. Though they all differ slightly, the recommended final mix temperature should be in the range of 40F to 90F. It is also very important to protect the installed materials from freezing for a minimum of 48 hours or until thoroughly dried. Failure to take into consideration ambient conditions at the time of installation could prevent the refractory material from reaching its proper strength.

The following formula is one way for estimating/adjusting the variables relative to mixing a refractory material (water temperature, air temperature, and storage temperature):

Tr = [(W x T) + .22 (Wc x Ts)] / (W+.22Wc)

Where:

Tr = temperature of mixed refractory (F)

W = weight of water (lb)

Wc = weight of dry refractory (lb)

T = temperature of water (F)

Ts = temperature of solids (F)

Using this formula and knowing the ambient conditions at the time of installation can help determine if the installed material was adversely affected by ambient conditions.

Were the correct curing procedures followed? Only after the refractory material has been properly cured and/or dried will the refractory material reach its design strength. Almost all refractory materials (except those that are phosphate bonded) must be cured prior to the drying process. Failure to properly cure a cement-bonded refractory material is the number one contributor to refractory failure and lack of longevity. Curing allows the chemical action to take place inside the refractory and helps ensure that the refractory can reach its maximum strength when properly dried.

One of the most important recommendations for proper curing of refractory is that the surface of the refractory be kept moist (using a curing compound, wet canvas bags, or spraying water) or that the surrounding atmosphere be kept humid for at least 24 hours.

Were the correct procedures followed? The dry-out or bake-out of the refractory will take place after the curing period. This process removes all mechanical and chemical water left in the installed material and allows the refractory material to reach its proper strength. Unlike the curing of refractory, which is done right after the installation (usually by the installing contractor), the dry-out can be completed anytime. However, this does not apply to phosphate-bonded refractory materials, because a phosphate-bonded material must be cured and dried at the same time. A phosphate-bonded material must be dried within the first two to three weeks after installation because a phosphate-bonded material will begin to absorb moisture from the surrounding atmosphere. Eventually, over a period of two or three weeks, the material will begin to slump and fall off.

New lining should be heated gradually to let the moisture escape and reduce internal stresses. The rule of thumb is that you base your hold time on the thickness of the thickest area refractory lining found on the entire work project. For example, if the thickest area is 4 inches thick, then the drying time is four hours.

The following is a general heating schedule under ideal conditions for a 1-inch-thick refractory lining on fluidized bed furnace walls:

- Raise temperature at 75F per hour to 250F to 400F range.

- Hold for 2 hours at 250F to 400F.

- Raise temperature at 75F per hour to 600F to 800F.

- Hold for 2 hours.

- Raise temperature at 75F per hour to 1,050F to 1,200F.

- Hold for 2 hours.

- Raise temperature at 75F to operating temperature.

In many applications, conservative heating rates can be followed without great penalty. But in some cases, such rates are uneconomical from a production standpoint. Each material has its own allowable deviation for conservative heating schedules. Check with the refractory manufacturer or refractory expert for a compromise between safe heating rates and operating costs. Failure to follow proper dry-out procedures can result in your refractory never reaching its maximum strength and will contribute to a spall at the refractory surface.

Were the correct quantities installed? Finally, to help ensure that the refractory material was not installed too thick or too thin, it is important to know the quantity of material required for a proper installation. This quantity can then be compared with the amount that was installed. For example, insufficient material installed on the lower furnace walls inside a fluidized bed boiler could contribute to excessive stud and tube wall failure; excessive material installed on the lower furnace walls inside a fluidized bed boiler, in conjunction with not following proper curing and/or drying procedures, could contribute to a complete refractory material failure.

Finding the root cause of a refractory material failure is usually like what you see on the TV show CSI-without the body. The site evaluation uses laboratory analysis of failed refractory and forensics to reconstruct the original refractory installation that may have occurred years earlier. Only by understanding all aspects of the design and installation of the refractory material can the root cause be identified and a repeated failure be avoided.

—Gary Bases, author of The Bril Book (a complete guide to brick, refractory, insulation, and lagging systems), is president of BRIL Inc., an independent consulting firm specializing in energy-saving solutions.