The Nuclear Regulatory Commission (NRC) has approved NuScale Power’s uprated 77-MWe (250-MWth) small modular reactor (SMR) design, clearing the nuclear technology firm’s second standard design approval (SDA). The development marks a boost for ENTRA1 Energy, NuScale’s exclusive commercialization partner, which is in “various stages of discussions with potential customers” in the U.S. and abroad, the company noted.

The NRC’s approval of NuScale’s US460 SMR design, completed in less than two years and below expected cost thresholds, is based on the federal regulatory body’s final safety evaluation report (FSER), which confirms the reactor meets all applicable safety requirements. NuScale’s SDA application for the US460 was accepted by the NRC in July 2023 and is based on the staff’s FSER, issued on May 28, 2025.

While a significant regulatory and technical achievement for NuScale, the design was notably geared toward first implementation at the Carbon Free Power Project (CFPP) at the Idaho National Laboratory (INL), a project canceled in November 2023 after municipal utility participants withdrew, citing escalating costs and shifting market conditions.

Despite the cancellation, NuScale’s leadership emphasized during its first quarter earnings call on May 12 that lessons learned from the CFPP have informed ongoing customer engagement, supply chain development, and project structuring. “We are proud to be a first mover in the industry when it comes to manufacturing preparedness, a crucial step towards deployment, and we continue to gather early valuable knowledge about the process that will only make it more streamlined and efficient as well as enhanced scalability going forward,” CEO John Hopkins has said.

A Second Uprated Iteration

The 77-MWe US460 design builds on NuScale’s 50-MWe module (US600), whose design the NRC certified in July 2022—making it the first small modular reactor (SMR) design to complete the agency’s design certification process. Notably, the NRC’s certification of NuScale’s 50-MWe model became only the seventh reactor design approved for use in the U.S., joining advanced light-water technologies such as the AP1000, ESBWR, and APR1400. NuScale’s first SDA was granted in September 2020 for its original 50-MWe (US600) SMR design. The second SDA approves NuScale’s uprated 77-MWe (US460) SMR design.

Unlike combined licenses, which authorize construction and operation at specific sites, NRC design certifications are rulemaking actions that confirm a reactor design’s compliance with safety requirements independent of location. Valid for 15 years and renewable, design certifications allow future applicants to reference the approved design in their own construction and operating license (COL) applications. In contrast, an SDA is a staff-level approval of a major portion or the entirety of a reactor design, documented in a safety evaluation report, which can be referenced in future construction or operating license applications but does not have the same legal standing or finality as a design certification, meaning issues resolved in the SDA process can be revisited in subsequent licensing steps.

“A standard design approval indicates that a proposed reactor design meets applicable agency safety requirements,” the NRC noted in its announcement. However, “Companies that seek to use the US460 design would have to file applications seeking permission to build and operate a nuclear reactor using the approved design.”

Essentially, the US460 design increases NuScale’s output per module to 77 MWe while preserving its core safety philosophy and passive features that define the company’s approach. The NRC’s review, following a graded approach focused on risk significance, confirmed that the US460 meets all applicable safety requirements under 10 CFR Part 52, Subpart E.

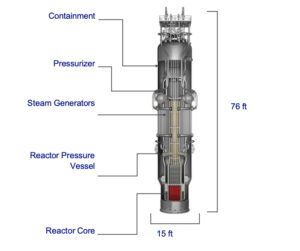

As the NRC’s documents note, the US460 plant configuration allows up to six factory-fabricated modules per facility, providing a total output of approximately 462 MWe. Each module is a fully integrated pressurized water reactor (PWR) with the reactor core, two helical-coil steam generators, and a pressurizer contained within a single reactor pressure vessel (RPV) and housed in a compact steel containment vessel (CNV). The modules are partially immersed in a below-grade pool, providing an additional passive heat sink and enhancing both safety and security.

The NRC’s FSER documents a rigorous, risk-informed review of the US460 design, employing a four-tiered classification of systems, structures, and components (SSCs) based on safety significance, applying the most detailed scrutiny to those with the highest risk impact.

- Probabilistic Risk Assessment (PRA). Confirmed that the design achieves a core damage frequency significantly lower than the current U.S. light-water reactor fleet.

- Passive Safety Systems. Validated the ability of the ECCS, decay heat removal, and control room habitability systems to function without external power or operator action.

- Fuel and Thermal-Hydraulic Performance. Assessed through a combination of CHF testing, steam generator performance tests, and full-system integral tests using the NuScale Integral System Test Facility.

- Human Factors Engineering. Evaluated the control room design, operator workload, and digital control systems, incorporating lessons from both nuclear and non-nuclear industries.

The NRC also reviewed the applicant’s quality assurance, in-service inspection, and startup test programs, ensuring that the plant can be constructed, operated, and maintained in accordance with regulatory requirements. The FSER identifies COL information items that future applicants must address, including site-specific seismic, hydrologic, and meteorological characteristics; operational programs; and emergency planning.

Readying for New Prospects

According to NuScale, the NRC’s approval of its uprate will enable ENTRA1 Energy Plants “to provide a wider range of off-takers and consumers with reliable, carbon-free energy.”

As Hopkins underscored in May: “In collaboration with our exclusive commercialization partner, ENTRA1 Energy, we are in various stages of discussions with potential customers both here in the U.S. and abroad. Domestically, this includes discussions with government officials and industries, including data centers, utilities, coal plant operators transitioning to nuclear and petrochemical and energy companies; internationally, with stakeholders around the globe in Europe, the Middle East, Africa and Asia.”

According to NuScale, ENTRA1 is leading plant development, structuring, and financing through a flexible project delivery model designed to mitigate deployment risk and meet diverse customer needs. These include off-taker power purchase agreements (PPAs), build-own-transfer frameworks, and co-development structures with fees and royalty payments. NuScale says the model is central to its strategy of de-risking capital-intensive projects while enabling broad adoption across sectors.

Data centers offer a prominent prospect, Hopkins suggested. “On the data center front, ENTRA1 continues to lead discussions with major U.S. hyperscalers with a strong focus on powering [artifical intelligence] operations. Potential customers continue to be attracted to ENTRA1’s commercial model, which is designed to provide financial flexibility while mitigating deployment risks,” he said.

“Of these customer discussions, I would classify upwards to 10 as advanced, many of which have progressed to the point of multiple iterations of term sheets exchange between parties and customer site visits to Doosan’s manufacturing facilities in South Korea, where NuScale power modules are being built. Across the board, we are continuously encouraged that both prospective customers and the broader market are better informed and more aware of the significance and advantages of NuScale’s advanced SMR technology, in part due to our extensive outreach efforts.”

Hopkins and other officials suggested that NuScale’s leadership has deliberately pivoted from preliminary agreements and memorandums of understanding (MOUs) to securing binding contracts, with a goal of booking a firm customer order by the end of 2025. NuScale has reiterated that it “remains the only SMR technology company with design approval from the NRC, and the company remains on track for deployment by 2030.”

Keen Focus on Supply Chain Buildout

To ready for the burgeoning SMR prospects, the company has placed a strategic emphasis on strengthening its manufacturing supply chain, anchored by Doosan Enerbility in South Korea and supported by long-term partners including Framatome, Paragon, and IHI in Japan. “Doosan has the capacity to put out about 20 modules a year. We’re also in discussions with other of our key suppliers, such as IHI manufacturing in Japan,” said CEO John Hopkins. “What we’re keeping very close on is, to your point, we don’t want to overextend our capacity to execute. And our model is just what you said. It’s always been these are fungible assets that are going to be built in a factory and shipped to multiple locations. So we don’t want a one-off project at a time. We want multiple projects.”

However, CFO Robert Hamady emphasized that while the current supply chain is positioned to deliver at scale, NuScale is planning conservatively. Unlike gigawatt-scale conventional reactors, NuScale’s SMR modules are factory-built, manufactured in parallel, stored if needed, and shipped just-in-time—a design choice the company says is essential to meeting the aggressive deployment timelines demanded by industrial off-takers. “I think today, there is expectation that our supply chain could take up to 20 modules a year. And I’ll be honest. In my financial modeling, I’m more conservative,” Hamady said.

Still, he suggested the ecosystem is primed to expand rapidly once orders are secured. “Money instigates money. It instigates investment. And I think that our supply chain has been great partners—great, great, great partners,” he said. “We’ve invested in design finalization, and our supply chain partners invested in that as well.” NuScale’s seven-to-eight-year supplier relationships could prove decisive as competition tightens. “The nuclear supply chain is tight. It’s very specific. There’s a limited number of suppliers, but fortunately, we’re the first SMR company to go into production,” he added. “Once we have a first contract, I think you’ll see more money going into the supply chain in order to increase capacity … and we’re planning for that already.”

International Prospects: The RoPower Project

So far, NuScale’s most advanced international project is the RoPower initiative in Romania—a flagship partnership with Romanian utility Nuclearelectrica to repurpose the former Doicești coal plant into a multi-module SMR facility. Based on NuScale’s US460 design, the project will host up to six 77-MWe factory-built modules for a total capacity of 462 MWe. Fluor is leading Phase 2 Front-End Engineering and Design (FEED).“Notably, we are on schedule to deliver the Class 3 estimate by this fall. Furthermore, discussions are underway to extend the project into the detailed design phase, a critical step that would enable the submission of a final investment decision application to the Romanian government by late Q1 or early Q2 2026,” Hopkins said.

NuScale serves as both the technology provider and a key engineering partner for RoPower, with its scope including licensing, design engineering, and technical support—activities that are already contributing to the company’s revenue stream. However, while the project is advancing and generating engineering and licensing revenue for NuScale, it is not yet final. The ultimate go-ahead depends on the successful completion of the FEED study, delivery of the Class 3 cost estimate, and a positive final investment decision by Romanian authorities, currently targeted for late 2025 or early 2026.

The project is structured around a two-phase final investment decision (FID) process to ensure robust due diligence, according to Hamady. “RoPower has taken a very sensible and measured approach to the development of the project,” he said. “And I think what RoPower now is looking at is … greater assurance, I think, on our side and greater assurance to the market that ultimately at the end of FEED Phase 2, RoPower will have completed sufficient engineering studies to get to an FID, which is final investment decision, and be able to take a view of moving forward with the project.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).

Correction: An earlier version of this article incorrectly stated that certification of the US460 would make it the eighth reactor design approved for use in the U.S. In fact, the NRC granted a Standard Design Approval (SDA) for the US460 in May 2025, which is not a design certification. Only the 50-MWe NuScale design (US600) has completed the NRC’s design certification process. We regret the error and thank our readers for their attention to detail.