The first GE 7F gas turbine began commercial operation 30 years ago this month. Since coming on the market, more than 950 7F machines have been commissioned, including four 7F.04 units that entered service recently at Techint’s Norte III combined cycle power plant in Mexico.

The 907-MW Norte III facility is located in the municipality of Ciudad Juárez, in the state of Chihuahua. GE will operate and maintain the plant for 25 years under an agreement signed with Techint in 2018.

“We chose GE to collaborate with us on the Norte III plant because of its reliable technology and total plant-service solutions,” Alejandro Maluf, CEO of Techint North America, said in a statement.

7F Gas Turbines Will Help Power Growth in the Region

The Chihuahua region was identified as a deficient node in Mexico’s 15-year infrastructure development program for the enhancement of the country’s national electric system—PRODESEN 2017–2030. The Norte III combined cycle plant will help alleviate the deficiency.

“We believe this important project will allow the consortium to leverage our collective global expertise in infrastructure, energy and project financing to support the expected growth in the Chihuahua region as was identified in the PRODESEN 2017–2030 plan,” said Maluf.

A Long History of Success

GE’s first 7F unit entered commercial operation on June 6, 1990, at Virginia Power’s Chesterfield site, which is about 15 miles south of Richmond along the James River. As POWER reported last year, the Chesterfield project marked the beginning of the golden era for gas turbine technology.

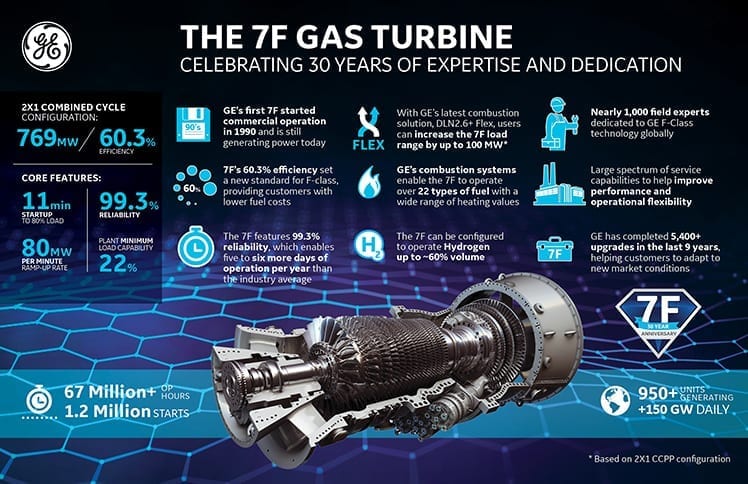

Since that plant was commissioned, almost 700 7F units have been constructed in the U.S. and Canada, while more than 90 have gone up in Latin America, 85 have been constructed in Asia, and 80 have been built in the Middle East. The 7F design has more than 67 million operating hours and more than 1.2 million starts.

Don Brandt, former manager of GE gas turbine engineering, was a guest on The POWER Podcast in September 2019. Brandt has been called the father of the F-class gas turbine, but he was hesitant to accept all the credit. “I can’t express enough the number of people and the skills—the broad skills—that made that F machine a success,” he said.

The 87-year-old engineer reminisced about his career with GE and touched on some of the challenges that the company faced while developing the F-class unit. “Just the little thing like the rolling of a thread became critical to the success of the F machine, because if that thread broke, you lost the continuity of the rotor, the rotor would vibrate, the machine would shut down, it wouldn’t be a success,” Brandt recalled. Ultimately, his work and that of many other engineers and technicians led to arguably the most successful gas turbine ever built.

The late John Lammas, during an interview with POWER in July 2019 when he was GE Power’s chief technology officer, suggested the F-class was a “pivotal” development for the industry. “The F-class was really one of GE’s developments—and that was taking the existing machines, and looking at them, and knowing there was a need for a larger, more-efficient machine. And I think that’s happened more than a couple of times in our history,” Lammas said.

Mexico Is a Big Market for GE

Mexico comprises GE’s third-largest installed base of 7F gas turbines. To help support the fleet, GE has a 16,000-square-meter service center in Morelia, Michoacán, Mexico. The service center provides maintenance, testing, and repair solutions for the Latin American region.

“We are proud that our gas turbine technology and total plant solutions including O&M [operations and maintenance] services will help meet the growing electricity demand in Mexico, while offering capacity and efficiency guarantees tailored to meet Techint’s needs,” said Eric Gray, vice president for the Americas region with GE Gas Power. “The [Norte III] project was performed with the highest standards of quality and safety in crucial collaboration with FieldCore, the field services execution team owned by GE, providing productive and reliable results for our customers including Techint.”

As part of the 25-year operations agreement, GE will provide a full spectrum of digital solutions, including GE’s Asset Performance Management and Operations Optimization solutions to help predict and reduce unplanned downtime and improve power plant productivity. The company said its software will provide direct support to the GE O&M team in achieving the guaranteed capacity outcome.

—Aaron Larson is POWER’s executive editor (@AaronL_Power, @POWERmagazine).