Battery Energy Storage Systems (BESS) are revolutionizing our power grids, dramatically enhancing resilience, and facilitating greater integration of renewable energy sources like solar and wind. This technological evolution promises a cleaner, more sustainable energy future, but it also introduces significant new risks, particularly fire safety challenges. High-profile incidents involving lithium-ion battery systems highlight critical gaps in traditional fire suppression methods, especially regarding thermal runaway—a dangerous condition where battery cells rapidly overheat, leading to fires that are difficult to control.

Real-world incidents such as the fires at Moss Landing and McMicken BESS facilities underline the urgency of rethinking our approach to fire safety. To safely capitalize on BESS’s immense potential, it’s vital to adopt proactive, innovative solutions. Among these, immersion cooling technology has emerged as a frontrunner, effectively preventing ignition and controlling thermal events right at their inception.

Fire Risk Profile of BESS

Key Causes of BESS Fires

Lithium-ion battery fires typically originate from several core risk factors. These factors compromise battery stability and can trigger dangerous chain reactions within the energy storage system. The most common causes include:

- Electrical faults, such as internal short circuits or external overcharging, which lead to uncontrolled current flow and overheating.

- Manufacturing defects, including misaligned electrodes or contaminants, that weaken the battery’s internal structure and make it prone to failure.

- Mechanical damage, which may occur during transportation, installation, or operation, physically compromising the battery casing or separator.

- Battery aging and degradation, which reduces the effectiveness of thermal and electrical control mechanisms, increasing susceptibility to failure.

- Gas buildup and cascading thermal events, particularly in tightly packed battery modules, where the failure of one cell can trigger a chain reaction among neighboring cells.

These types of failures escalate quickly and are often accompanied by intense heat and the release of flammable, toxic gases. As a result, lithium-ion battery fires are especially hazardous, presenting significant challenges to emergency response teams and traditional fire suppression systems.

Unique Suppression Challenges

The distinct nature of lithium-ion battery fires presents several suppression challenges. Unlike typical fires, lithium-ion fires do not require external oxygen to sustain combustion, making traditional oxygen-deprivation methods largely ineffective once thermal runaway has begun. Suppression strategies must simultaneously achieve multiple objectives—rapidly cooling overheated cells, halting the spread of thermal runaway, and containing the release of hazardous gases.

Traditional suppression methods, which might be adequate for conventional fires, often prove inadequate or ineffective against the intense and self-sustaining reactions characteristic of lithium-ion fires. Consequently, traditional fire suppression solutions may become quickly overwhelmed, escalating the risks to personnel, property, and surrounding environments.

Traditional Fire Suppression Methods: Context, Capabilities, and Constraints

Water Mist and Hybrid Water-Based Systems

Water mist systems operate by discharging fine droplets that efficiently absorb heat, cooling batteries and limiting the spread of flames. These systems are highly effective in providing rapid initial cooling, slowing or potentially halting fire progression when applied promptly.

However, water mist systems have significant limitations. Risks include potential electrical shorts in systems without robust insulation, and their effectiveness diminishes greatly once thermal runaway has set in deeply, as internal battery reactions can reignite the fire despite external cooling.

Inert Gas and Clean Agent Systems

Inert gas and clean agent systems rapidly extinguish fires by removing oxygen, offering swift, residue-free suppression ideal for sensitive equipment environments. They are electrically non-conductive, reducing risks of equipment damage from suppression activities.

Nevertheless, their limitations are substantial. These agents must be deployed immediately upon detecting a fire; otherwise, their effectiveness rapidly declines. They also cannot halt thermal runaway chemical reactions already underway within the battery cells and require airtight enclosures and expensive refills after use.

Aerosol-Based Suppression

Aerosol suppression systems disperse potassium-based compounds to chemically disrupt combustion, proving highly effective in small, enclosed spaces, such as compact battery cabinets. These systems are advantageous due to their compactness and ease of installation.

On the downside, when used on their own, these systems have notable limitations. They do not provide any active cooling, which means residual heat, especially from lithium-ion batteries, can lead to reignition even after a fire is initially suppressed. Their effectiveness also diminishes in larger, open battery enclosures, making them less suitable for full-scale BESS deployments without additional thermal management measures.

Dry Powder Suppressants

Dry powder suppressants rapidly extinguish localized lithium-ion battery fires by absorbing heat and preventing oxygen access. They can quickly control small-scale fires and are often used effectively in emergency handheld extinguishers.

However, their limitations include extensive residue creation, complicating cleanup and potentially damaging equipment irreversibly. Additionally, their messy nature and limited scalability severely restrict their practical use in modern, large-scale, containerized, or outdoor BESS installations.

Clearly, traditional suppression methods offer limited risk reduction for modern, large-scale battery storage applications. Addressing these challenges demands a shift toward innovative, proactive solutions.

Immersion Cooling: Fire Prevention and Passive Suppression in One System

Thermal Management: How Immersion Cooling Works

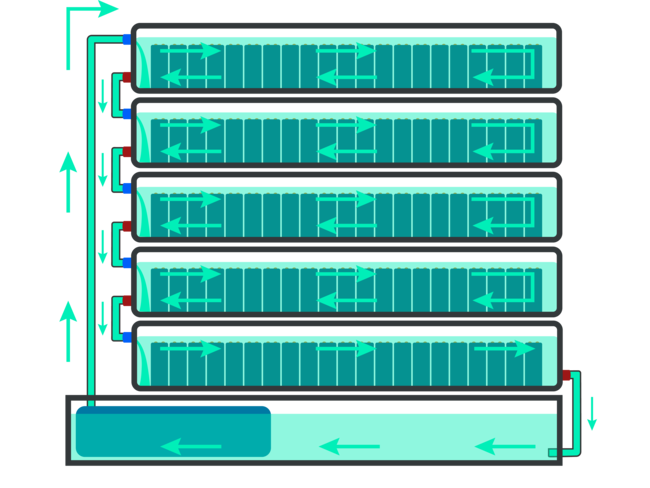

Immersion cooling technology involves fully submerging battery cells in a non-conductive dielectric fluid, establishing a highly efficient direct heat transfer pathway. This process effectively prevents the formation of thermal hotspots that lead to degradation and runaway conditions.

Unlike conventional air or liquid plate cooling, immersion cooling directly contacts the entire battery cell. This continuous and uniform temperature management throughout the battery array dramatically reduces battery degradation and fire risks before they can emerge.

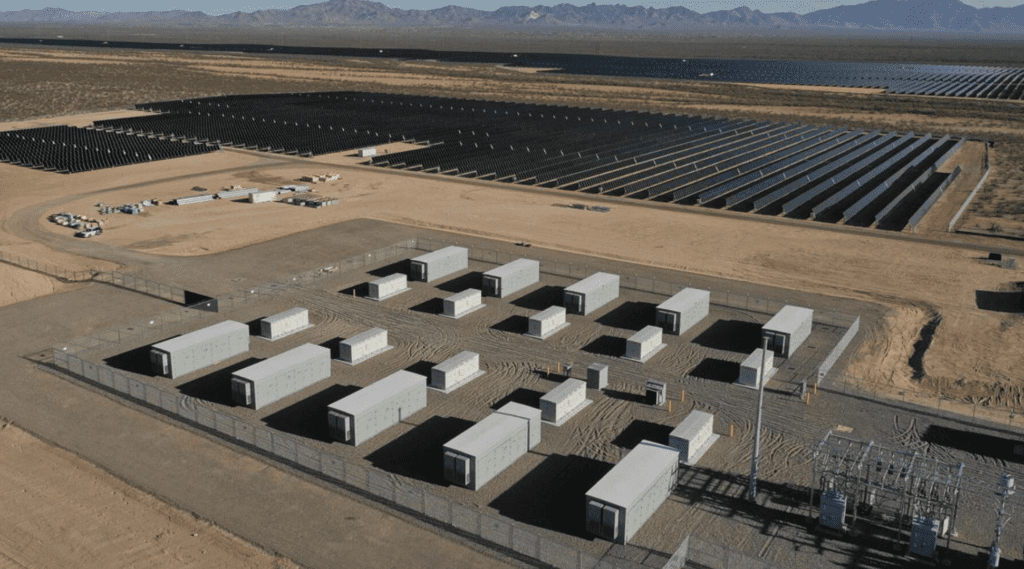

Additionally, EticaAG’s immersion cooling system (Figure 1) is integrated with the Battery Management System (BMS). If the BMS detects any rise in temperature beyond normal operating thresholds, it automatically activates a proprietary circulation system. This circulation mechanism increases fluid movement around the affected battery cells, accelerating heat removal and restoring safe thermal conditions before a critical situation can develop.

Passive Fire Suppression: Suppression Without Activation

In addition to thermal management, immersion cooling fluids inherently provide passive fire suppression capabilities. By enveloping battery cells completely, the fluid displaces oxygen and immediately smothers any potential flames, eliminating combustion.

Furthermore, if a battery cell begins to fail (Figure 2), the fluid swiftly isolates the affected cell, preventing cascading failures that could escalate into severe thermal events. This passive system removes the need for complex activation mechanisms or pressurized suppression agents, significantly simplifying maintenance and enhancing operational reliability.

Safety, Scalability, and Sustainability

EticaAG’s immersion technology (Figure 3) utilizes fluids that are readily biodegradable, non-toxic, and non-corrosive, making them suitable for diverse installation environments, both indoors and outdoors. These fluids leave no residues, eliminating secondary damage to equipment and significantly reducing downtime after an incident. Additionally, the environmental impact of immersion cooling fluids is far lower than chemical-based suppressants, underscoring their sustainability credentials. These combined benefits translate into safer, cleaner, and more manageable long-term maintenance of BESS facilities.

Safer, Smarter BESS Designs

Traditional fire suppression methods typically offer incremental improvements, primarily addressing fires after they ignite. In contrast, immersion cooling fundamentally redefines BESS safety by proactively eliminating ignition conditions altogether.

At EticaAG, the advanced immersion cooling system, LiquidShield, exemplifies this forward-thinking approach. LiquidShield delivers immediate fire risk mitigation through proactive thermal management and passive suppression, dramatically enhancing reliability, environmental sustainability, and safety. Engineers, project developers, and regulators must prioritize these comprehensive, innovative solutions to fully realize BESS’s potential, ensuring safer, more sustainable energy storage for future generations.

—Matthew Ward is president of EticaAG, a leader in battery energy storage solutions for mission-critical infrastructure.