Reverse osmosis (RO) is a vital water purification technology used in various applications such as boiler feedwater treatment, cooling water systems, and wastewater recycling. The feedwater for RO can originate from municipal sources, wells, rivers, lakes, or even seawater. Here’s an overview of the reverse osmosis process, particularly as it’s applied in power generation (Figure 1).

|

|

1. An industrial reverse osmosis system includes pre-treatment, filtration, and membrane components, as well as pumps and controls. Source: Envato Elements |

Pre-Treatment. Before entering the RO system, most feedwater undergoes pre-treatment to eliminate larger particulates, sediments, and organic matter. This typically involves coagulation, clarification, and filtration. The primary goal of pre-treatment is to achieve feed water with a turbidity of less than 1.0 and a Silt Density Index (SDI) of less than 3.0. Effective pre-treatment significantly improves the downstream operation of the RO unit.

Cartridge Filtration. Following pre-treatment, the water passes through cartridge filters (typically 1 to 5 micron) just before the high-pressure pumps. These filters serve as the last line of defense against upsets in the upstream process. They are dead-end filtration style and should be replaced when the differential pressure increases by about 10 psi. Frequent replacement of cartridge filters often indicates that the upstream pre-treatment systems are not performing effectively.

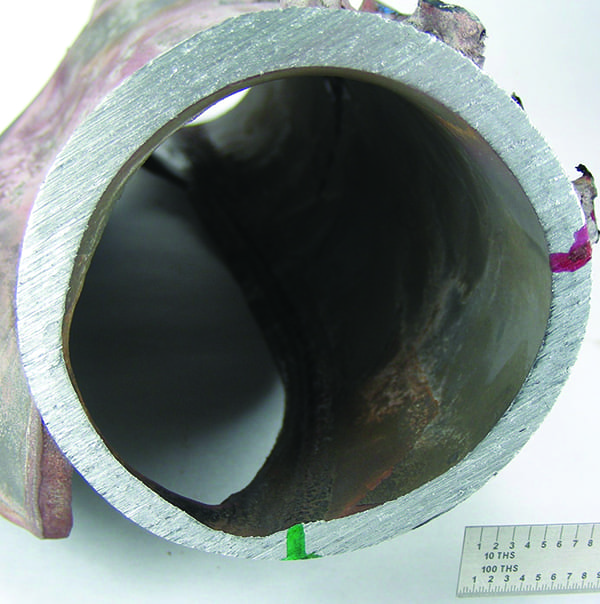

Membrane Separation: The Heart of the RO. High-pressure pumps force the water through a semi-permeable membrane. This membrane allows water molecules to pass through while rejecting dissolved salts, minerals, and other contaminants. It’s important to note that high-pressure pumps are very sensitive to low suction pressure. The pressure required to push water through the membrane varies depending on factors like feedwater quality, temperature, membrane type, and salinity. RO system design regularly requires detailed water analysis and sound engineering calculations. Pressure requirements are often determined through pilot testing or established design parameters for specific membrane types and operating conditions. The RO process typically involves two or three stages:

■ First Stage. The feed water enters the first stage, passing through membranes housed in pressure vessels. These membranes remove up to 99% of dissolved salts and contaminants. The purified water (permeate) is collected, while the concentrated impurities (brine) are directed to the next stage.

■ Second Stage. The concentrate from the first stage is further processed in the second stage membranes, utilizing residual pressure to remove up to 99% of the more concentrated contaminants. The permeate from this stage is collected and combined with the permeate from the first stage. The resulting concentrate is then sent to a third stage or, in some cases, directly to drain if a third stage is not in use.

■ Third Stage. If utilized, the concentrate from the second stage is processed in a third stage, where residual pressure helps remove even more concentrated contaminants. The final concentrate may then be disposed of or undergo additional treatment.

The number of vessels and membranes decreases in subsequent stages to maintain appropriate crossflow velocities, as recommended by the membrane manufacturer. Most industrial RO units have two or three stages, with one to 10 vessels per stage, and each vessel can contain one to seven membranes.

A wide variety of configurations and membrane types are available today. It’s important to understand that multiple stages do not equate to better treatment, as all permeate only passes through the membrane once. While the example above describes subsequent stages relying on residual pressure, some more advanced or higher salinity units may incorporate booster pumps to aid in pushing the more concentrated feedwater through the membranes in those stages.

Most power plants have some type of demineralization system, and of those, most of them are centered around an RO system. Some resin-based demineralization systems are still in use, but unless the feedwater total dissolved solids concentration is quite low, it’s more expensive to operate the older technology. Dedicated engineers specializing in water treatment technology are available to audit demineralization plants to see if systems can be optimized and/or upgraded to meet today’s requirements.

—Wes Starnes is president of Water Wrights, a company specializing in water treatment equipment.