Focus on O&M

-

Coal

Breathing Added Life into Failing Heat Exchangers

When heat exchanger tubes—sometimes numbering a thousand or more per unit—begin to crack or wear, the effects can lead to a cascade of subsequent failures in adjacent tubes. If too many tubes are plugged, heat exchanger effectiveness is compromised, and power generation may be curtailed. If conventional mechanical plugs are used, they can break loose, leak, and fail. At that point, the replacement of a very costly heat exchanger is imminent.

-

Gas

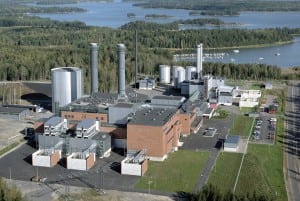

Local Warming: Helsingin Energia Uses CHP to Heat a City

Power plant operators, especially those located in countries with enforceable carbon emissions standards, are concerned about their CO2 emissions. But for Helsingin Energia—which provides power, heating, and cooling for Helsinki, Finland’s 300,000 residents—the main concern is local warming, not global warming. In Helsinki, temperatures on midsummer afternoons only reach an average 21C, and for half the year daytime temperatures are below 10C.

-

O&M

New Coating System Extends Life of Cooling Tower

American Electric Power’s (AEP’s) Cardinal Power Plant Unit 3 cooling tower in Brilliant, Ohio, was coated and lined in the spring of 2008 by a team of coatings professionals that included the plant’s project and coatings engineering staff, Sherwin-Williams (coatings supplier), Cannon Sline Industrial (contractor), and OTB Technologies (third-party inspector). The team completed the project in just 11 weeks through damp springtime conditions in the Ohio River Valley.

-

O&M

New Process Transforms Waste into Product for Controlling Emissions

In April, Solvay Chemicals Inc. commissioned a new facility that uses an innovative process to recover and transform sodium carbonate waste streams into a market-grade sodium bicarbonate used in air emissions control.

-

News

Shoring System Uses First Built-In Ladder Supports

Safety is the imperative for any construction project, and Duke Energy’s 630-MW Edwardsport integrated gasification combined-cycle station in Knox Country, Ind., is no exception.

-

O&M

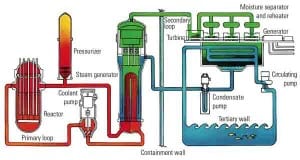

Variable-Frequency Drives Upgrade Reactor Circulating Pumps

A recent trend in nuclear power plant upgrades has been the replacement of the motor-generator (MG) sets that drive the reactor circulating pumps with variable-frequency drives (VFD). Siemens’ first application of VFDs in this industry began in 2000 with an installation of six VFDs at the Browns Ferry Nuclear Plant. The use of the VFD continues to expand, and upgrades were recently completed at several U.S. plants, including the Hatch Nuclear Plant in Georgia.

-

Business

KEMA Conference Report: Competition Strengthens as Wholesale Power Prices Fall

Since the collapse of Enron and the wholesale power markets, the vitality of competition in retail markets for electricity has waned in most regions of the U.S., with the exception of Texas. At KEMA’s 21st annual Executive Forum in late March, 300 attendees converged on Dallas to discuss and debate the dynamics and changes now facing residential and commercial customers in most regions of the U.S. and Canada. Founded in 1927, KEMA is a global provider of business and technical consulting, operational support, measurement and inspection, and testing and certification for the energy and utility industry. A summary of the many presentations follows.

-

News

Design of Experiments Reduces Time to Market

Dresser Waukesha is a familiar name associated with large, gas-fueled stationary engines for power generation and gas compression applications around the world. Each new project location presents a unique set of site variables that must be taken into consideration—such as fuel quality, air/fuel ratio, temperature, humidity, altitude, load, and exhaust after-treatment—when providing the customer a meaningful performance guarantee. To fully characterize every engine option with such a wide range of fuel types and quality and in widely varying environmental conditions across the global is an impossible chore.

-

News

Keep Oil Leaks Under Control

An oil skimmer could simplify your plant water maintenance activiites.

-

O&M

Competitive Maintenance Strategies, Part III

This third and final installment addresses three more areas where an investment in good maintenance practices pays operating availability dividends.