Focus on O&M

-

O&M

Understanding Boiler Code Compliance and Magnetic Level Gages

A magnetic level gage may be an excellent addition to a power plant boiler’s drum-level instrumentation. However, before any changes are made, owners must first understand the specific minimum requirements for water level instrumentation defined by the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. The code requires a functional water gage […]

Tagged in: -

O&M

Technical Guidance Documents Provide Global Standards

The International Association for the Properties of Water and Steam (IAPWS) is an international nonprofit association of national organizations concerned with the properties of water and steam, particularly

Tagged in: -

O&M

Using Radar to Improve Security and Counter Drone Threats

Security is taken very seriously at most power plants. Fences and other barriers are usually installed before construction of a plant even begins to keep curious busy-bodies, thieves, protestors, and—at the far end of the spectrum—saboteurs and terrorists out of sensitive locations. Some plants have dedicated security staff patrolling areas both inside and outside of […]

-

Coal

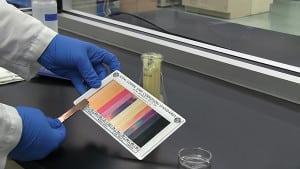

Coal Treatment Helps Power Plant Reduce Fuel Costs

Lakeland Electric, the third-largest public power utility in Florida, reported that it saved $12 million in fiscal year 2015 through the use of a coal treatment at its McIntosh Power Plant Unit 3. The savings

Tagged in: -

O&M

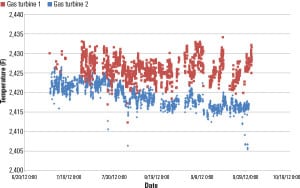

Efficient Use of Power Plant Process Data Improves Asset Management

Asset data is crucial in the power generation industry. Without it, utilities are forced to speculate about how long their assets will last, when they will need repair, and which strategies will maximize plant efficiency. With it, plant owners have the tools to drive down operational and maintenance costs while ensuring highly reliable power delivery. […]

Tagged in: -

O&M

All About Lubricant Additives

Lubricant additive technology is a complicated business because it involves several different chemistries. Often, one additive can adversely interact with another additive as they both compete for the same area on substrate surfaces. This kind of interaction can lead to the canceling of the additives’ desired properties. Conversely, the use of different additive chemistries can, […]

Tagged in: -

Legal & Regulatory

TVA Uses Advanced Technology to Store and Monitor Coal Ash

At 2:45 p.m., Nicholas McClung’s cellphone chirps during a business meeting. He doesn’t bother to look at it; the special chirp says it all. He politely excuses himself from the meeting and rushes to the Tennessee Valley Authority’s (TVA’s) Advanced Technology for Impoundment Monitoring (ATIM) center in the basement of the company’s Chattanooga headquarters. When […]

-

O&M

Boiler Tube Failure Thermohydraulic Analysis

Eskom operates 23 power stations in South Africa with a total capacity of more than 42 GW. It supplies about 95% of all the electricity used in the country. One of its coal-fired power stations was experiencing frequent boiler tube fatigue failures in the hopper section—the bottom part of the boiler—of all six units. The […]

Tagged in: -

O&M

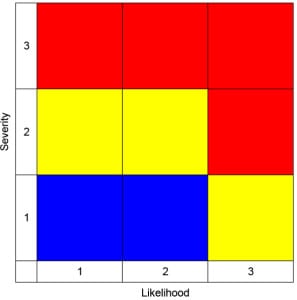

Use Near-Miss Incidents as a Preventive Tool

Broadly put, today’s power plant operations are a mix of automated operations and manual or procedural steps. A plant may have hundreds of control loops, interlocks, permissives, and safety systems. In

Tagged in: -

O&M

Ultrasonic Diagnostic Tool Detects Leaks, Bearing Wear, and Corona Discharge

Air leaks cost money. According to the U.S. Department of Energy (DOE), over $5 billion per year is spent on energy to power compressed air systems. The DOE estimates that optimizing these systems could

Tagged in: