Features

-

Coal

An SCR Can Provide Mercury Removal Co-Benefits

Complying with various state (and expected federal) requirements governing mercury removal from the stack gas of coal-fired power plants has usually been achieved by adding an expensive activated carbon injection system. Now there is another alternative: a catalyst that features higher mercury oxidization activity than conventional catalysts while maintaining the same SO2 to SO3 conversion activity—and all at a lower operating cost. Full-scale installations are under way at several Southern Company plants that burn a variety of coals.

-

Instrumentation & Controls

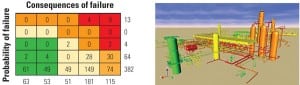

Managing Equipment Data Through Asset Virtualization

Asset “virtualization” extends and combines the technologies of 3-D visualization and virtual reality to a new, practical level for the life-cycle management of power industry equipment. All pertinent data for a component, subsystem, or plant is associated with, stored, and accessed through as-built 3-D digital models of the actual plant that are constructed using laser scanning techniques.

-

Coal

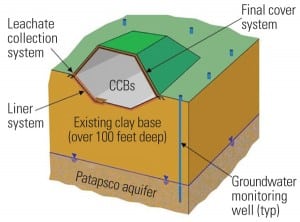

Constructing Maryland’s First Permitted Landfill for Coal Combustion By-products

Constellation Power Source Generation Inc., which owns and operates three coal-fired power plants in Maryland, has contracted with Charah Inc., an ash management company, to build a landfill to strict environmental requirements for the disposal of its plants’ coal combustion by-products that can’t be recycled for other uses.

-

Gas

Top Plant: Irsching 4 Combined Cycle Power Plant, Irsching, Bavaria, Germany

The Irsching 4 Combined Cycle Power Plant has set a new world record in power plant efficiency with its new SGT5-8000H gas turbine. With an output of more than 578 MW and efficiency of 60.75% (net) achieved at a world record test run in May 2011, the plant demonstrates that climate protection, low-cost power generation, and flexible operation using fossil fuels can be attained simultaneously through technical advances. Due to its high efficiency, the gas-fired plant uses significantly less fuel and produces lower carbon dioxide emissions than traditional combined cycle plants.

-

Gas

Top Plant: Montoir-de-Bretagne Combined Cycle Plant, Montoir-de-Bretagne, France

The 435-MW Montoir-de-Bretagne gas-fired power plant is ramping up Gallic generation in the Loire-Atlantique region of western France. The plant’s innovative natural gas combined cycle technology offers high efficiency and low emissions.

-

Gas

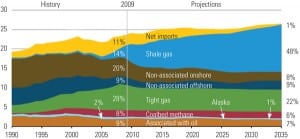

Global Gas Glut

Marcellus Shale gas has increased recoverable natural gas reserves in the U.S. by about a third over estimates prepared a few years ago. Europe is also exploring shale gas as an alternative to problematic Russian gas supplies and low proven natural gas reserves. POWER contributors in the U.S. and UK examine the comparative economic value, public acceptance, and political implications of these massive shale gas reserves.

-

O&M

The New Water Lab

Recent advances in water laboratory instrumentation—from improved sample conditioning to advanced online instruments—have reached the market. Here’s a look at the equipment you’ll find in the best-equipped power plant laboratory this year.

-

Coal

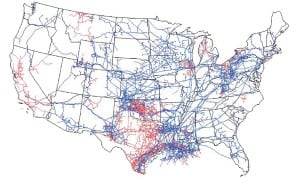

Best Practices for Natural Gas Line Cleaning

As barriers to new coal-fired generation expand and enthusiasm for nuclear plants wanes, the commissioning of natural gas–fired plants promises to increase. However, gas plants pose hazards, too. An explosion last year that was caused by unsafe use of natural gas to blow residue from a gas pipeline during commissioning of a gas-fired power plant has focused regulator and industry attention on finding safer alternatives for this task. Fluor shares its gas pipeline cleaning best practices.

-

Gas

Who Pays for Firming Up Variable Energy Resources?

The major economic hurdle for renewable power generation technologies continues to be substantial installation costs. But another cost is associated with continuous load-balancing, made possible by backstopping that variable generation with dispatchable generators that typically consume expensive fossil fuels. Bottom line: Who pays for the capacity firming or backstopping resources?

-

Gas

Top Plant: Arvah B. Hopkins Generating Station, Unit 2, Tallahassee, Florida

Known for its progressive, pro-sustainability policies, the City of Tallahassee recently repowered a 30-year-old conventional steam plant unit, turning it into a new 300-MW facility. The utility redesigned the Arvah B. Hopkins Generating Station, Unit 2 as a 1 × 1 combined cycle plant in order to improve efficiency, switched the primary fuel from oil to natural gas, and thereby reduced fuel costs and emissions. The plant’s flexible design even will enable expansion to a 2 × 1 configuration when additional capacity is needed in the future.