As commercial and industrial facilities face growing pressure to reduce emissions, lower costs, and build resilience into their operations, the spotlight has shifted to power. At Hutchinson Aerospace and Industry’s Ithaca, Michigan, facility (Figure 1), this shift has translated into a multi-year transformation focused on energy precision: leveraging data, digital monitoring, and system-level upgrades to cut power consumption while improving operational outcomes.

|

|

1. Hutchinson Aerospace and Industry has reduced power costs and optimized operations by adopting an energy strategy that includes leveraging data. The plant, located in Ithaca, Michigan, features digital monitoring and system-level upgrades as part of its push to decarbonize and make the facility more efficient. Courtesy: Hutchinson Aerospace and Industry |

The facility in 2024 surpassed its 2030 goal of achieving 50% carbon neutrality—a milestone driven not by the purchase of offsets or premium-rate green power, but by real reductions in energy use and emissions intensity. Through a combination of demand-side upgrades, smarter controls, and a rigorous energy management framework, the site has created a living blueprint for how manufacturers can optimize energy systems and future-proof their operations.

Pursuing Carbon Neutrality: Reductions First, Not Credits

The Ithaca facility’s decarbonization efforts began with a practical goal: use less power, use it more efficiently, and get more from each kilowatt consumed. The team conducted a comprehensive energy audit, targeting core systems including compressed air, HVAC (heating, ventilation, and air conditioning), process heating and cooling, lighting, and high-load aerospace test equipment. Load profiling and sub-metering established baselines for each system.

One of the most impactful projects tackled the site’s largest compressed air load, involving 22 air-powered agitators used in volatile paint mixing. These had been running with inefficient 1-horsepower (hp) vane gearmotors. The plant replaced them with more efficient 1/2-hp direct-drive piston air motors, significantly reducing air consumption while improving process control. In some cases, air use was cut by more than 90%. The change also allowed operators to monitor and control mixing speeds with new tachometers, a process improvement that enhanced both product quality and safety.

Local utility Consumers Energy recognized the upgrade as a standout efficiency success and provided $20,000 in incentives to help offset the cost. The project now saves an estimated $3,000 annually per agitator and had an average payback of less than one year.

The facility still draws electricity from Consumers Energy’s standard fuel mix, currently about 15% renewable and 85% fossil-based. But its focus has remained squarely on operational efficiency. Scope 1 direct emissions dropped significantly due to reduced compressed air demand, and Scope 2 emissions declined on a per-unit basis as electrical systems were fine-tuned to avoid waste.

Although Consumers Energy offers an option for businesses to purchase 100% renewable electricity for a premium, Hutchinson Ithaca has chosen not to pursue this route. In Michigan, companies can technically declare themselves carbon neutral through such purchases, but the Ithaca team believes real-world reductions in usage matter more than paper-based claims. Instead of simply checking a box, the site is working to deliver measurable environmental impact.

Smart Systems and Real-Time Controls: How Power Use Got Smarter

The real gains came not from any single upgrade, but rather from how the facility re-engineered the way power is used and managed. Compressed air optimization, for example, included a system-wide pressure reduction from 111 psi to 100 psi following leak remediation and efficiency tuning. That seemingly small change translated into substantial energy savings without performance losses.

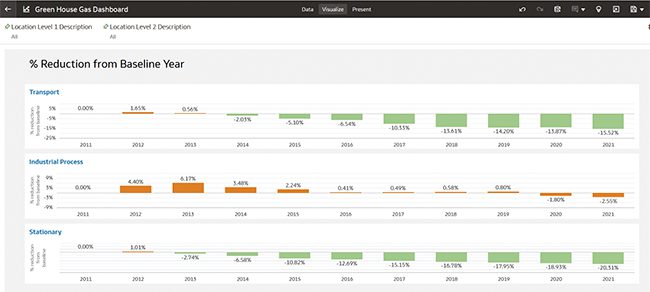

|

|

2. Hutchinson’s manufacturing facility in Michigan draws electricity from Consumers Energy’s standard fuel mix, currently about 15% renewable and 85% fossil-based. The plant’s focus has remained squarely on operational efficiency. The facility’s Scope 1 direct emissions have dropped significantly due to reduced compressed air demand, and Scope 2 emissions have declined on a per-unit basis as electrical systems have been fine-tuned to avoid waste. Courtesy: Hutchinson Aerospace and Industry |

Production startups were another area of transformation. Previously, multiple systems activated simultaneously at shift change, creating demand spikes and unnecessary charges. Now, using a real-time monitoring portal provided by Consumers Energy, teams stagger activations based on actual production needs (Figure 2), smoothing load curves and reducing peak demand penalties.

Daily operations now rely on detailed visibility into load profiles by hour, zone, and equipment type. This allows the plant to identify anomalies, correct drift, and respond to changing conditions in near real time. Behavior has changed too; operators now time system warm-ups and shutdowns to align with actual production instead of habit or convenience.

Utility Partnerships and Demand Readiness

A strong partnership with Consumers Energy has been central to Hutchinson Ithaca’s progress. Through the utility’s demand response program, the plant committed to shedding 250 kW of load during peak grid events. Though no formal curtailment was called for in 2024, the plant maintained its readiness and received a $9,000 credit for its participation.

More importantly, the program enabled installation of a transformer-mounted smart meter and access to a digital energy portal. These tools now drive many of the site’s operational decisions, especially around idle loads and off-shift consumption. For example, newly available data revealed energy use patterns during nights and weekends, prompting schedule changes and turning off systems that didn’t need to run outside production hours.

Consumers Energy also supported compressed air audits that helped identify leaks and justify system improvements. As the system improved and leak frequency fell, the site’s maintenance program evolved from reactive repairs to proactive leak prevention.

Dust Collection Retrofit: Load Matching in Action

One standout retrofit project involved the site’s main dust collection system, which previously relied on a 125-hp motor running continuously at full load. The system’s energy use didn’t vary with production volume, wasting substantial power during low-demand periods.

After retrofitting with variable-speed drives and press-tied dampers, the fan system now adjusts in real time based on actual airflow needs. This load matching strategy cut energy use by more than two-thirds and improved workplace air quality. Performance was validated through pre- and post-retrofit monitoring, and the project earned more than $12,000 in rebates from Consumers Energy.

ISO 50001 Certification: A Formalized Energy Framework

In December 2023, Hutchinson Ithaca earned ISO 50001 certification, formalizing its approach to energy management and aligning operations with international best practices. This milestone wasn’t the beginning; it was a reflection of work already underway. The plant had been following the core principles of the standard for years, so certification was a natural next step.

Today, the site’s Environmental Management System (EMS) and Energy Management System (EnMS) are fully integrated. Every energy project begins with a project charter that outlines objectives, risks, metrics, and required resources. This approach promotes internal accountability, ensures alignment with broader sustainability goals, and provides clear documentation for utility partners and third-party auditors.

Equipment Upgrades and Power Rationalization

Ongoing equipment upgrades have further boosted efficiency. In 2024, five outdated hydraulic presses were decommissioned due to high energy use and reliability concerns. They were replaced with modern equipment that draws just 30–50 amps, compared to 50–70 amps for the legacy models, and shuts off automatically when idle. Operators report fewer issues, reduced downtime, and improved ergonomics.

Other systems, such as press 14 and a dip line, are currently under review. Real-time monitors now track power consumption and idle time, giving the team the data it needs to rationalize or replace equipment strategically rather than reactively.

Culture as Catalyst

While technology and equipment upgrades have driven savings, culture has been the true catalyst for lasting change. Today, energy awareness is a part of daily life, from how shift meetings are run to how systems are started and stopped.

Large-load systems that once powered on automatically now start “just in time” based on actual production schedules. Weekly planning meetings now include a review of energy performance data, and frontline operators feel empowered to suggest improvements. This cultural shift has made energy management a shared responsibility rather than a top-down mandate.

The Next Phase: Onsite Generation and Deeper Electrification

Looking ahead, Hutchinson Ithaca is preparing for a second wave of transformation. Plans include rooftop solar installation, further integration of variable-speed drives, and deeper electrification where practical.

The focus will remain on projects with clear, measurable impact: those that cut waste, improve up time, and strengthen the plant’s long-term resilience. While the facility has not yet pursued renewable energy purchasing programs, onsite generation is seen as a strategic way to increase independence and reduce exposure to future rate fluctuations. As these projects move forward, real-time monitoring and utility collaboration will remain essential tools.

A Scalable Model for Industrial Power Strategy

Hutchinson Ithaca’s results demonstrate that energy strategy can be more than a cost center; it can be a driver of performance, resilience, and long-term value. For other industrial facilities looking to modernize their power systems, the message is clear:

■ Start with Data. What gets measured, gets managed and improved.

■ Right-Size Demand. Don’t just automate—optimize. Match energy to real operational need.

■ Avoid Shortcuts. Operational reductions have more lasting impact than marketing claims.

■ Leverage Partnerships. Utilities can be valuable allies when goals are clearly defined.

■ Build a Culture. Sustained progress only happens when everyone is invested.

In an era of tightening margins and rising energy scrutiny, Hutchinson Ithaca is showing what’s possible when power becomes a core part of business strategy—not just a background cost.

—Donald English is the maintenance manager, and environmental health and safety manager at Hutchinson

Aerospace and Industry.