Partner Content

-

Partner Content

Discover the Power of Digital

Discover the Power of Digital

eBook: 14 Power Companies Show Tangible Gains with Digital

From balancing asset life and performance to managing variations in market conditions and fuel costs, power leaders everywhere are using data and analytics as a strategic asset to drive efficiencies and increase profitability for their business. In this eBook, learn how they -

Partner Content

What to Look for in an Industrial Cleaning Supplier

Your company is growing: The number of products you manufacture and the pace at which they are produced require a new post-production strategy. Your capacity to properly execute technology-based industrial cleaning projects must adapt to the changing needs of your company and keep up with your fast-moving operation. A reliable, respected industrial cleaning supplier can

-

Partner Content

Reduce Business Risk and Protect your Operations

Reduce Business Risk and Protect your Operations

5 Security Imperatives for Power Executives

Your peers are feeling the urgency to assess their attack surface and put in place the right processes and technology:64% Power leaders believe their security strategy not aligned with today’s risk environment

> 90% Power leaders say growth is only achieved through enhanced management of -

Partner Content

MPW Mobile Ultrafiltration and Demineralization Units Exceed Canadian Power Plant Expectations

Challenge:

After a major refurbishment, a Canadian nuclear plant required additional process and boiler feed water for plant start-up and commissioning.

The plant’s raw water supply contained measurements ranging from 1-10 NTU, conductivity from 70-100 and color units ranging from 180-420. The plant also experienced highly variable flow rates, ranging from 0-600 GPM, and issues with the -

Partner Content

MPW’s technology leads to superior cleaning at Ohio plant

Challenge

A global polymer producer located in Ohio sought to improve the annual outage cleaning of its heat exchangers.

Historically, industrial cleaning contractors hand lanced the heat exchanger tubes, servicing four to six exchangers per night for two weeks to fit within the outage schedule. But often, multiple heat exchangers would require re-cleaning to allow for heat -

Partner Content

The Cloud Advantage

The Cloud Advantage

6 Reasons Power Leaders are Moving to Cloud

Gaining business value from massive volumes of asset sensor datarequires a unique operating environment not typically part of the power infrastructure. What must power leaders consider when taking steps to transform their operations with data and analytics?

Discover the power of digital in the cloud in -

Partner Content

MPW’s Automated Bundle Blaster

MPW’s Bundle Blaster Side Cleaner system is designed to remotely clean the shell side of small to medium

sized tube bundles, up to 36 feet in length. The tube bundle is placed on hydraulically actuated rollers to

incrementally turn the bundle during the cleaning process while the cleaning head runs horizontally on a track

over the bundle. MPW’s -

Partner Content

Powering The Future

Discover the Power of Digital

White Paper: Powering the Future

Leading the Digital Transformation of the Power Industry

By:

Marco Annunziata, GE’s Chief Economist

Ganesh Bell, Chief Digital Officer of GE Power

Digital technologies are transforming the power sector. From delivering power to underserved markets to managing variations in market conditions and fuel costs, power leaders are using analytics and -

Partner Content

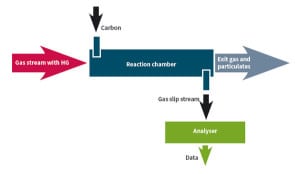

Improve Your Mercury Compliance Testing

US power generators and cement plants are now under pressure due to recent legislation. Many plants are now scrambling to tighten up their mercury control procedures. Luckily, ADA Carbon Solutions’ Dynamic Mercury Index test has been developed to ensure consistent quality of sorbents used in activated carbon injection.

-

Partner Content

MPW’s Improvements Lead to Savings for Southeastern Pulp and Paper Facility

Problem

A Florida pulp and paper mill faced a complicated, dangerous process to clean its power boiler during scheduled outages.

Previous efforts to clean the boiler included manual water blasting from scaffolding, which posed a safety risk to workers below due to the potential for falling debris.

Solution

The Operations team at MPW Industrial Services recommended that the facility’s -

Partner Content

Free eBook: 7 Ways to Achieve Operations Reliability

Learn how power leaders are leveraging Asset Performance Management (APM) to drive less unplanned downtime, safer operations and a competitive edge.

-

Partner Content

Case Study: MPW’s Automation Simplifies RO Replacement Process for Indiana Energy Plant

Case Study: MPW’s Automation Simplifies RO Replacement Process for Indiana Energy Plant

-

Partner Content

Case Study: MPW’s Emergency Response Pays Off for Virginia Power Station

INDUSTRIAL WATERMPW’s emergency response pays off for Virginia Challenge:

When a Virginia power station had an issue with its existing Reverse Osmosis [RO] process, it called on MPW to supplement its water needs during an excessively cold winter.

The plant lost RO functionality at one of its four power-production units, which would severely damage its ability to -

Partner Content

Case Study: Monitoring Health and Performance of Grid-Scale Battery Installations

UniEnergy’s Technologies (UET) manufactures and installs large-scale energy storage solutions for utility, commercial, and microgrid applications. Their battery systems enable customers to address power needs, such as “frequency regulation” as well as “transmission generation deferral” and “peak shaving. This case study details how OSIsoft’s Connected Services enabled UET to offer capacity guarantees for their technology.

-

Partner Content

MPW Industrial Water Capabilties

For over 30 years, MPW Industrial Water Service has worked to provide customized and expert solutions for our clients that chop operating costs in half. We offer professional water services that rise to the occasion during an emergency, or to provide long-term purified water needs that rank as some of the best in the industry.

https://vimeo.com/151532115#download

{

background-image: -

Partner Content

Special Report: Condition Monitoring – The Next Steps

Today, power plants have the ability to collect more and better data about how their assets are performing in the field. But what are you doing with that data and how can it provide value to your customers?

-

Partner Content

Video: How Connected Services Fits the Needs of a Large Scale Energy Storage Company

UniEnergy Technologies, a clean tech large scale energy storage company, needed data from all of their customer sites so they could continue to make improvements to their batteries and maintain those batteries at the customer sites. Find out how the utilized Connected Services to accomplish this and increased the value of their aftermarket services with

-

Partner Content

Webinar On-Demand: Improving Asset Management with Real-Time Condition Monitoring and CBM

This webinar will provide you with information on how you can implement Condition Based Maintenance (CBM) based on real-time condition monitoring using the PI System. You’ll learn about:

Four possible methodologies

Best practices for designing a CBM strategy

How Williams a large scale energy infrastructure company, implemented CBM

-

Partner Content

Video: Condition Based Maintenance Demonstration for Power Generation

Demo: The PI System for Condition Based Maintenance

This video demonstration using the PI System for Condition Based Maintenance (CBM) includes the, management, analysis and presentation of historic and real-time data. You’ll see it from a plant engineer’s perspective, including operational data for a specific asset, notification, an event frame report, and how the process data -

Partner Content

eBook: Implementing Condition-Based Maintenance Using Real-Time Data

This guidebook provides recommendations for integrating operational data when implementing Condition Based Maintenance (CBM) solutions. Content includes:

– a getting started guide to developing a successful CBM implementation

– CBM configuration including quantitative and qualitative based meters

– a PI System ecosystem overview for condition monitoring

– CBM solution examples

….and more! -

Partner Content

Case Study: Fingrid Oyj’s Investment in a Real-Time Condition Monitoring System Pays Off

With a network combining about 14,000 km of transmission lines and more than 100 substations, Fingrid Oyj, the electricity transmission operator in Finland, needed to find new ways to optimize network reliability while minimizing maintenance and investment costs. Download this case study to find out how they accomplished this.

#download

{

background-image: url(https://partners.decisionbriefs.com/osisoft/wp-content/plugins/decisionbriefs-partners/content/icons/download-icon.png);

background-repeat: no-repeat;

padding-left: 54px;

padding-top: 18px;

height: 30px;

font-size: 16px;

clear:both;

}Download

-

Partner Content

How to Protect Control Assets before the Cybersecurity Egg Cracks

The target is on the back of industrial control systems (ICS) within the power and process industries. The number of attacks, as reported by the Industrial Control Systems Cyber Emergency Response Team (ICS-CERT), has increased sixfold since 2010. Control systems at industrial facilities present a more attractive target to hackers as they offer a greater

-

Partner Content

ENR RANKS NATIONAL STEEL CITY THIRD LARGEST STRUCTURAL STEEL ERECTOR IN NORTH AMERICA

Ranking fueled by a 66 percent revenue jump to $97.7M in 2014; NSC also moves up from #302 to #203 among the nation’s Top 600 specialty contractors.

Plymouth, Mich., Nov. 30, 2015 – National Steel City, one of the nation’s leading steel construction and erection companies, today announced it has been ranked the third largest structural -

Partner Content

Case Study: Exelon Ensures Nuclear Power Plant Safety Using Online Monitoring

Exelon has optimized the efficiency of its operations, maintenance, and engineering staff. By automating data collection, plant engineers now focus on analyzing data rather than manually collecting data and risking radiation exposure. Download this case study to get more details then go here to learn more about Condition Based Maintenance (CBM) for Power Generation.

-

Partner Content

Ash Utilization: Managing Byproduct Impacts for MATS

Our newest research paper demonstrates the possibilities for utilization of ash in concrete in post-MATS compliance scenarios. A new test is introduced to monitor ash quality, and then is applied to real-world utility ash and PAC ranges to show the impacts.

-

Partner Content

Condition-Based Maintenance Bolsters the Bottom Line in Power Generation

The power generation industry is undergoing a period of rapid transformation. A growing number of operators are considering the adoption of condition-based maintenance (CBM). This whitepaper discusses the forces that are driving demand for CBM, how CBM works and why it is an effective alternative to planned maintenance strategies.

Find out more about CBM for Power -

Partner Content

Handling Dry Sorbent Reliability

Learn more about key processes for safely handling dry sorbents as you introduce a mercury control solution into your plant process.

-

Partner Content

7 Ways Power Generation Service Providers Can Benefit from a Connected Services Approach

Across the Power Generation industry, companies face a multitude of obstacles to achieving high operational efficiency. Domain experts are retiring in growing numbers and being replaced by less experience workers. Discover the benefits of a unique approach to overcoming this and other challenges by downloading this list.

You can find out more about OSIsoft and this -

Partner Content

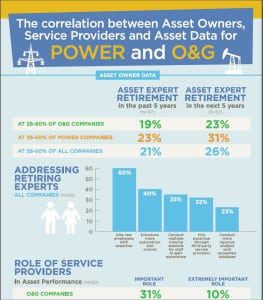

Infographic: Challenges and Opportunities in the Power Industry

A recent study conducted by Zpryme shows how service providers can deliver the expertise energy companies need as they lose their asset experts—89 percent of power and oil & gas companies expect to lose experienced personnel due to retirement in the next five years, and 35 percent will see more than 25 percent of their