Partner Content

-

Partner Content

Predictive Approach to Resin Exhaustion Monitoring

A unique deionization capacity monitoring algorithm monitors the exchange capacity of deionization systems and accurately predicts resin exhaustion before leak or breakthrough, regardless of water quality.

-

Partner Content

On-line chloride and sulfates monitoring prevents corrosion

Continuous monitoring of chlorides and sulfates using microfluidic capillary electrophoresis (MCE) technology provides a proactive approach to controlling the impact of some of the most corrosive contaminants in power plant water. Find out how Nearman Creek Power Station in Kansas City simplified the process with on-line measurement.

-

Partner Content

Public Protection Strategies for 8 Critical Infrastructure Sectors

The Department of Homeland Security (DHS) has defined 16 critical infrastructure sectors in the U.S. IT professionals can utilize best practices to contribute to the overall safety and security of these sectors. Threat analysis should consider the likelihood of a particular group or categorization of cyber adversary.

Once defined, the tactics, techniques, and procedures that are -

Partner Content

A Revolution in Process Safety and Maintenance Management

Intelligent Sensor Management (ISM) is an innovative technology for process analytical measurement solutions that simplifies sensor handling, enhances reliability and reduces sensor lifecycle costs. Learn more.

-

Partner Content

Albert: The Smart Networking Monitoring Solution for Utilities

Most network monitoring solutions are now offering next-generation threat detection methods that use machine learning to reduce false positives and detect anomaly network traffic. Albert is a passive IDS offered by CIS as a low cost and very effective network monitoring service for which threat detection is based on threat signatures.

-

Partner Content

MD&A IBECS® – The Integrated Solution to Power Plant Control and Monitoring

Sponsored by:

Power plant control and monitoring can be complex given the need to integrate many different platforms. Adding to the complexity is the fact that HMI’s (Human-Machine Interface) supplied by the OEM often only interface with the OEMs controller and not with ancillary systems. Lastly, ongoing support and updates from the common operating system may be […]

-

Partner Content

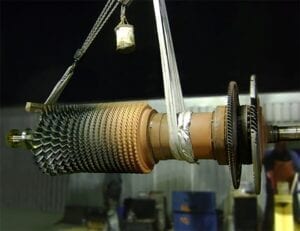

Gas Turbine Major and Generator Test & Balance

Sponsored by:

Mechanical Dynamics and Analysis (MD&A) was contracted after a forced outage to perform a major overhaul on a cogeneration unit’s MS5001PA gas turbine, and to remove, test and inspect the generator field. Because the unit dispatches as baseload and the turbine is a critical asset, MD&A was asked to complete the repair work as quickly […]

-

Partner Content

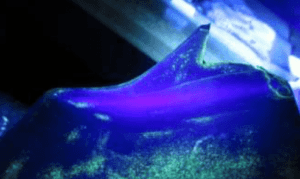

Generator Rotor Stub Shaft Repair

Sponsored by:

Mechanical Dynamics and Analysis (MD&A) was retained by a utility to perform a stub-shaft repair of a generator rotor collector-end shaft. The customer reported that the generator rotor had suffered a collector ring failure and also a ground to the main shaft. Major arcing and heat damage occurred to the generator rotor forging shaft. The utility weighed […]

-

Partner Content

Gas Turbine Parts Lifetime Extension Clinic

Sponsored by:

MD&A’s San Antonio Service Center can extend the service life of gas turbine components whose OEM service limit has passed or whose configuration is no longer suitable to operate. Significant savings can be realized by opting for lower-cost repaired spares instead of new parts. Elevated temperatures take a big toll on gas turbine components. Repair […]

-

Partner Content

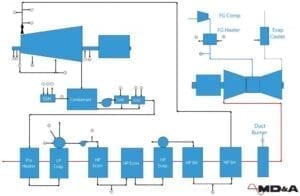

Thermodynamic Analysis on a Steam to Combined Cycle Plant Conversion

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) experts recently performed a thermodynamic analysis to assist our client in converting their coal and natural gas plant to combined cycle operation. The customer was able to locate a gray market Gas turbine and Heat Recovery Steam Generator (HRSG). Our team modeled how each component would interact with one another, and were […]

-

Partner Content

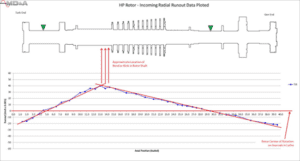

A-10 Rotor Straightening & High Speed Balance

Sponsored by:

Mechanical Dynamics and Analysis inspected and repaired an A-10 frame High-Pressure rotor. The unit was a 3600 rpm, 90 MW combined cycle unit. MD&A’s Turbine-Generator Repair Facility performed the incoming inspections / evaluations, repair straightening of the rotor, final inspections, as well as high speed balance. Incoming inspections and evaluation consisted of blast cleaning, NDE, visual inspections, […]

-

Partner Content

Deriving CO₂ and pH from Conductivity Values for Power Plant Cycle Chemistry

pH and CO2 measurement are central to efficient power plant cycle chemistry. Advanced process analytics instruments can provide accurate, calculated pH and CO2 determination from three simple conductivity measurements.

-

Partner Content

Reduce boiler corrosion and chemical costs with accurate pH measurement.

Appropriate and accurate pH chemical dosing into a power plant’s water cycle is essential to minimizing waste of chemicals and boiler corrosion. Precise measurement can save pH chemical dosing costs, help reduce corrosion, and maximize personnel safety.

-

Partner Content

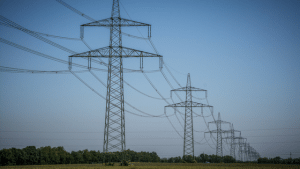

4 Ways Network Monitoring Keeps Utilities Safe

It’s no secret that people are concerned about the security of the U.S. power grid. Cyber criminals are always looking to exploit weaknesses in systems and networks. And unless you’re looking for malicious activity, you may not even know that your networks have been breached.

Network monitoring can be used to detect unusual behavior and provide -

Partner Content

4 Major Reasons Power and Utilities Should Work in the Cloud

It’s time for power and utilities to move to the cloud – here are 4 major reasons why.

-

Partner Content

Cybersecurity Strategies the U.S. Power Grid Should Apply

A multifaceted approach to cybersecurity can help power utilities provide defense against similar attacks.

-

Partner Content

Rent, buy, or lease? Learn how to make the smart choice for your site access mat needs

You know you need site access mats for your upcoming project. But should you rent, buy, or lease them? Making the right decision means considering many factors, including project duration, jobsite conditions, equipment, mat quality – even the potential for extreme weather. In this white paper, you will learn how to navigate the decision and choose the option that saves you time, money, and headaches. Find out the questions you must ask potential suppliers, and what happens when jobs go longer than planned.

-

Partner Content

GDPR – A New Regulation

Let’s take a look at how organizations can take the first few steps towards GDPR compliance.

-

Partner Content

Let’s Get Serious About Securing the Nation’s Critical Infrastructure

Protecting the nation’s critical infrastructure is becoming much more difficult in the face of escalating cyber attacks as well as the increasing complexity of systems underlying our critical infrastructure.

-

Partner Content

All Change – From gas to oil

Large scale projects typically involve many stakeholders, contractors and suppliers, which can lead to increased complexity and more challenging situations. Delivering such projects on time and within budget requires considerable coordination and management skills; traits that one US energy company needed in order to complete its most recent expansion project.

-

Partner Content

Cybersecurity and the U.S. Power Grid

Most of the nation’s critical infrastructure is Internet-dependent and is the target of persistent cyber attacks. Learn what organizations can do to increase the security.

-

Partner Content

Power Utilities are Vulnerable to Cyber Attacks Like Spear Phishing

Find out what spear phishing is and how it can leave power utilities at risk.

-

Partner Content

Sargent & Lundy to Present at HRSG Forum

February 28, 2018 – Sargent & Lundy is presenting at the Heat Recovery Steam Generator (HRSG) Forum, taking place March 5-7 in Houston. The 2018 agenda for the forum features presentations from around the world, presented by the world’s foremost experts on HRSG and related equipment.

Daniel Azukas of Sargent & Lundy is presenting Remaining Useful Life Assessment of -

Partner Content

Sargent & Lundy to Present at the 22nd Annual International Pressure Equipment Integrity Association (IPEIA) Conference

February 28, 2018 – Sargent & Lundy is presenting at the International Pressure Equipment Integrity Association (IPEIA) Conference, which takes place March 7-9, in Banff, Alberta, Canada.

Marc Lemmons of Sargent & Lundy will address the Alberta government rule mandating that power generation from coal-fired sources be eliminated by 2030, with the lost capacity replaced with that -

Partner Content

Sargent & Lundy Attending 2018 Energy, Utility, & Environmental Conference (EUEC)

February 27, 2018 – Sargent & Lundy is presenting a wide range of papers at the upcoming 2018 Energy, Utility & Environment Conference (EUEC). The conference takes place March 5-7 in San Diego, California. The papers will cover current energy and environmental topics:

Exploring Oxidation and SCR Catalyst on Gas Fired Units, presented by Emily Kunkel and co-authored by Raj Gaikwad -

Partner Content

Network Monitoring is Key for Public Power Utilities

Network monitoring can provide key cybersecurity insights into an organization’s netflow activity and rapidly detect unusual behavior.

-

Partner Content

A new method for corrosion prevention

Corrosion monitoring, control and prevention is an ongoing battle in today’s power plants. Two of the strongest indicators of how well that battle is being waged is to monitor the corrosive salts of chloride and sulfate.

-

Partner Content

Training to be the Best

Every business needs to have a skills training program to one degree or another. For those involved in more complex industries, such as oil and gas or petrochemical engineering, gathering new skills as well as the experience of the older generation and passing it onto those committed to learning a new trade is an essential business practice.

-

Partner Content

Advanced On-Line Sodium Measurement for Power Plants

Water treatment performance and determination of purity have depended on sodium measurement for nearly four decades. Monitoring cation exchange performance and the purity of power makeup water, steam and condensate has benefitted from measurement of this key parameter.

-

Partner Content

On-line Monitoring of Total Organic Carbon in the Water Cycle

Organic contamination in cogeneration water/steam cycles is capable of causing process disruptions and catastrophic damage to expensive capital equipment. Find out how to stop it in our white paper.

A Guide to On-line Conductivity Measurement

Conductivity and resistivity are widely used parameters for water purity analysis, monitoring of reverse osmosis, cleaning procedures, control of chemical processes and in industrial wastewater. Reliable results for these varied applications depend on choosing the right conductivity/resistivity sensor.

Electrical conductivity has been measured for more than 100 years and it is