As complexity rises across the power industry, modern control systems are becoming the foundation for next-generation solutions. By embracing automation, simulation, and artificial intelligence (AI)-ready architectures, forward-thinking organizations are setting the stage for more competitive operations.

Looking back over the last quarter century of the power industry, the demands and changes in the market have been surprisingly steady state, as compared to other industries. Over the past decade, the focus has been on retiring a significant portion of the world’s coal infrastructure and pushing toward renewable energy. However, much of the heavy lifting of decommissioning these aged assets has not come to fruition, and the push toward more efficient solutions has been far more focused on adding renewable energy sources to the existing base of traditional generation.

But as the steady-state behavior in the power grid’s generation, transmission, and distribution begins to change more rapidly, the next few years are shaping up to be remarkably dynamic. The industry will face a wide variety of new market conditions that are converging to create one of the most exciting times in history for those involved in the power industry. Consequently, companies will face increasingly—and alarmingly—more demand for energy to power data centers and other loads.

Along with this steep growth curve comes a strain on supply chain and engineering firms to deliver increasingly more complex projects on shorter timelines. Long lead times on turbines and other core components are resulting in life extension to plants previously slated for retirement. In addition, the world is facing a massive push toward software solutions using generative AI (artificial intelligence), and companies are monitoring the situation carefully to determine how it will impact their businesses.

Alongside these new challenges comes a growing need for data management. Companies are increasingly reliant on their enterprise software solutions and are trying to connect more disparate operational data to systems at higher levels in the organization than ever before—both in remote operation centers and at the enterprise level.

New Challenges Create New Dynamics

The increasing complexity of power generation and distribution is forcing companies to reconsider how they manage their automation technology. It used to be that features in an automation system were the last in line as a justification for the need to upgrade. Typically, cybersecurity needs and asset reliability were the driving factors for any modernization as asset owners aligned to North American Electric Reliability Corporation Critical Infrastructure Protection (NERC-CIP) regulations. Today, however, new features, such as the capability to integrate AI solutions for efficiency gains, are driving more teams to consider modernization.

As operational conditions continue to increase in complexity, the robustness and practical scope of automation platforms are increasing in parallel, creating the perfect onramp for emerging technologies to fuel the future of power generation and distribution. Control systems have more embedded technology than ever, creating an ideal platform for cutting-edge AI and advanced simulation solutions to drive faster, safer, more flexible and efficient operations. These new technologies will be critical to capturing competitive advantage in the coming environment, and forward-thinking organizations are relying on modernization to lay the groundwork to support those emerging innovations.

AI Will Expedite Talent Development

Like nearly every industry, companies in the power sector are experiencing talent attrition. As seasoned personnel retire, they have been replaced by new workers, who not only typically have less experience, but also tend to move between positions more frequently.

As a result, organizations are looking for ways to bring information closer to the people that are maintaining and designing systems, as well as trying to find ways to help operators make better decisions more quickly. Over the years, technology has always been part of this process as companies have leveraged various methodologies of storing information and recording best practices to help train and support less experienced personnel.

There have even been pockets of excellence over time regarding where those standards reside, along with ways to reproduce them for various projects. The limiting factor, however, has always been time and resources. Expert personnel—the very resource that is dwindling—have been necessary to drive those systems. AI is set to change that paradigm.

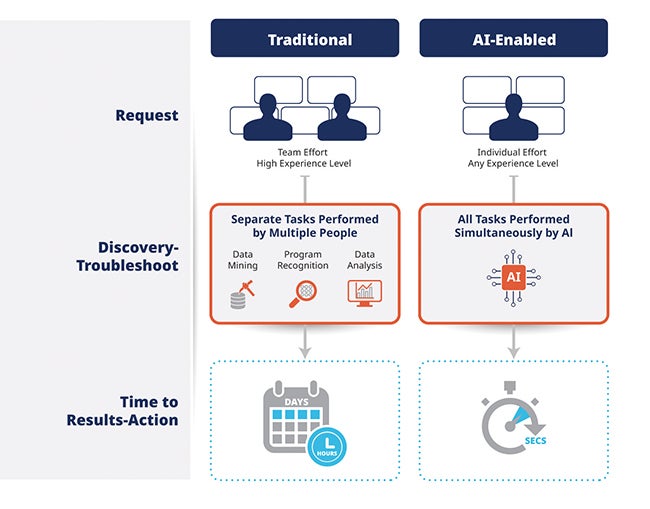

Previously, a team might have spent weeks combing through data and identifying recommendations, then testing those findings. Today, smaller groups of personnel can run the same datasets through an AI engine to often come up with the same or better results in seconds. Teams of any experience level can use these engines to immediately bring meaningful information to their fingertips with limited effort. Much of the data mining and pattern recognition necessary to float useful data to the surface can be completed much more efficiently using AI (Figure 1).

Clearly, AI is not ready to step in and handle all this analysis without a human in the loop, and it may never be in an industry like power where uptime and safety is paramount. There is still some doubt surrounding the results that AI models produce, and this caution is well-founded.

However, the fact that an AI model can produce so much consumable information so quickly and with such a low bar for entry allows teams to shorten the step of data aggregation and comparison. This means they can spend far more time in the much more valuable validation stage, turning data into action more quickly, while still maintaining integrity.

For example, consider a user performing a power plant startup. Varying ambient temperatures, operating parameters of the asset, and more can dramatically impact the correct startup steps. Using AI, an operator can quickly use natural language to ask, “During the last five startups, under these specific conditions, what were the most common challenges, if any? Were there ever issues with hot restarts? If so, what were the causes?”

If a human operator needed to do the same thing without AI assistance, it would require determining tags, figuring out the inputs and outputs, putting all that data on a trend, and performing analysis—a task that could take hours or days. AI can parse those questions, using real-world historical data to provide guidance, in mere seconds.

Such capabilities are game changers and will likely be critical to competing in the more complex energy markets just over the horizon. Fortunately, today’s most advanced control systems are being built with the capability to integrate AI technologies to accomplish these goals, and expert automation suppliers are even developing customized local AI models that can be seamlessly integrated with their control technologies.

AI Helps Build Smarter Simulations

As power industry organizations prepare for the smart grids of the future, and for training their personnel to navigate those more complex systems, simulation has become an indispensable technology. Digital twin simulations help teams create comprehensive training solutions to give operators and technicians real-world experience without the risk of interrupting live systems. Moreover, those same digital replicas can be used as powerful test beds, where teams can try out new control strategies and technologies to see how they will impact the overall system without safety or production risk (Figure 2).

Many digital twin solutions, from low to high fidelity, exist to provide testing and training platforms. However, the biggest challenge to simulation has always been synchronizing the simulation to the real-time control system data. The closer the digital twin can be to the actual plant operation, the better the testing and training will be for the personnel learning to control the assets. Today, the best systems have curator tools to take snapshots and move them to the simulation, but this still means synchronization happens on an on-demand, case-by-case basis—a very slow process.

Going forward, it will be possible to use AI to navigate this challenge. AI tools will not only be able to perform faster comparisons and error checking to help ensure teams can synchronize equipment and process states more frequently but will also be able to create training and testing scenarios based on historical and forecasted data to provide the best possible training environment.

For example, a trainer could ask the AI advisor to examine the plant’s last trip and identify the active parameters during that event. They could then either suggest different operating modes and have the AI engine run them in the digital twin to see how those actions might have led to better or worse outcomes, or they could ask the AI advisor to run hundreds or thousands of scenarios to suggest the best possible control actions that would have better handled the event.

Once the team has suggestions, it could use the digital twin to test those actions and see how impactful the difference is among different recommendations. Based on that knowledge, the team can work closely with the AI advisor to generate training scenarios to push knowledge of those best practices out to the personnel who need it. This type of quick access situational simulation with AI analysis can minimize human error, reduce process disruptions, and minimize maintenance/repairs over time.

While such an approach could be accomplished with traditional simulation technologies available today, it would be time-consuming and complex. As AI is more seamlessly integrated with simulation technologies and the control system, users will be able to ask such questions in natural language and receive incredibly fast responses from the system. Moreover, the AI advisor will have increased ability to see how anomalies over time lead to such events, and it can then explore existing interfaces to see if there are ways critical information could have been better presented to operators to make them aware of emerging problems earlier.

AI tools will also have the capacity to monitor who is in the control center at any given time, making it easier to track and trend operator performance, either by individual or by group. Armed with this information, teams will be better able to customize their training, giving different people and teams the unique tools they need to succeed.

Modernization Is Key

As AI and simulation technologies continue to redefine the landscape of power generation—helping to meet the increasing needs for electrification coming from data centers, behind the meter solutions, electric vehicles, renewable energy resources, and more—companies will need ways to implement these technologies quickly, easily, and most importantly, reliably (Figure 3).

One of the first critical steps to preparing an organization for a seamless and effective rollout of emerging technologies is modernizing to a control system designed to integrate seamlessly with those technologies. While bolt-on AI solutions will have their place, the most effective AI technologies will be those purposely designed for power from the ground up as part of modern control technologies and seamlessly integrated into the control system itself. Modernization to prepare for those technologies is one of the most critical steps an organization can take to prepare for the paradigm shift in power production, transmission, and distribution that will take the world by storm in coming years. ■

—Mike Ames is director of North America projects at Emerson’s Power and Water Solutions business.