Latest

-

News

DOE Offers Loan Guarantee to 845-MW Ore. Wind Farm

The Department of Energy (DOE) last week announced a conditional commitment to provide a partial guarantee for a $1.3 billion loan to the Caithness Shepherds Flat wind project, an 845-MW wind farm planned for eastern Oregon that it is calling “the world’s largest wind farm.”

-

News

NIST: Five “Foundational” Sets of Smart Grid Standards Ready

The National Institute of Standards and Technology (NIST), an arm of the Commerce Department designated by Congress to coordinate development of communication protocols, last week told the Federal Energy Regulatory Commission (FERC) it had identified five “foundational” sets of standards for smart grid interoperability and cybersecurity.

-

Commentary

Ash Me No Questions

The Environmental Protection Agency is expected to select its approach for future regulations regarding coal ash storage later this year. One option would be to continue classifying the waste as nonhazardous and leave enforcement with the states. Another option—the worst case for the power industry—would be a determination that coal ash is a hazardous waste, which would result in increased federal oversight and lawsuits.

-

Commentary

U.S. Power Sector Must Embrace Low-Carbon Future

The U.S. electric utility sector is undergoing a transformation unparalleled in its history. Extraordinary challenges, driven by the urgency of climate change and other market forces, are compelling the industry to abandon its century-old business model of building large, fossil fuel plants to sell increasing amounts of electricity.

-

Commentary

Biomass: Short-Term Drawbacks, But Long-Term Climate Benefits

In recent months, two noteworthy letters have been sent to Congress by eminent scientists examining the merits—or demerits—of biofuels in the climate debate.

-

O&M

Pulverized Coal Pipe Testing and Balancing

If you want the most accurate test results, it’s worth the extra effort to take isokinetic coal samples from coal pipes when collecting fuel and air measurements. Together, the data collected will allow more accurate balancing of coal pipes, measure fuel fineness, and improve the combustion efficiency of your steam generator.

-

Coal

EPA Air Regulations Shrinking Power Glut

Pending Environmental Protection Agency regulations to slash U.S. power plant emissions likely will lead to the closure of nearly 18% of the nation’s coal-fired generation capacity, trim demand for steam coal by 15% to 31% and boost demand for natural gas by 8% to 16%, a new Credit Suisse analysis concludes.

-

Coal

TVA Eyes Cleaner "Vision" with More Nukes, Less Coal

Responding to looming federal regulations to reduce power plant pollution, the Tennessee Valley Authority’s board signed off on a proposal to shut down 1,000 MW of older coal-fired generation and replace it with an equal amount of natural gas capacity while also pursuing 1,900 MW of demand response and energy efficiency programs and adding 1,140 MW of new nuclear generation by 2015.

-

Coal

EPA Boiler Regulations Will Strangle Construction of New Power Plants

An Environmental Protection Agency plan to tighten emission limits for new and existing industrial boilers has sparked alarmed protests from the biomass generation industry and electric utilities, who say the proposed regulations are so onerous they threaten to shut down existing biomass power plants and already are chilling deployment of new facilities.

-

Coal

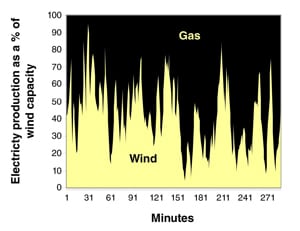

Overblown: Wind Power on the Firing Line, Part I

The conventional and oft-repeated truth is that wind generation directly reduces carbon emissions. Challenging the conventional wisdom has drawn much criticism from wind proponents, but the latest research has shown that wind has had, and will continue to have, negligible impact on the nation’s carbon emissions. The data are convincing and can no longer be ignored.