Managing the different oils and greases that make up your lubricant arsenal is a daunting task. Most power generation facilities employ a lubricant champion to keep those products carefully sorted and implemented. But like most highly skilled experts, lubricant champions can only do a great job when they’re properly supported. If you want to maximize productivity, you need to empower them with three essential tools: a high-quality lubricant, support from seasoned experts, and a strictly followed lubricant analysis routine.

The value of high-quality lubricants might seem obvious, since high-quality products are, by definition, better than most of their competitors. But the truth is that much of a lubricant champion’s skills and attention are wasted if they don’t have the best products to work with. And even the best products are likely to flounder if they aren’t implemented by a knowledgeable lubricant champion.

Modern lubricants are highly specialized and meticulously developed products with highly specific applications. A turbine oil might be designed to shed water, while engine oil is going to be designed to capture that moisture. Gear oil often has extreme pressure additives—unless it’s for a worm gear, which wouldn’t utilize those same additives. A properly supported lubricant champion can spend the time necessary to sort through all these variables and choose the best product for every facet of your operation—then make sure that those applications are monitored in the appropriate way. Investing in high-quality products then increases the benefits of your champion’s efforts.

Closely related to the benefits of high-quality lubricant products is the expert support that is often packaged with those lubricants. Even for a fully informed and experienced lubricant champion, expert support from the lubricant manufacturer can be incredibly valuable. These experts spend years building relationships within their designated territories, resulting in a comprehensive and up-to-date understanding of how an industry operates in a specific region.

For example, I once visited a customer who couldn’t identify the source of their lubricant contaminations—but my visit revealed that their storage facility had open drums. Though the warehouse was meant to stay sealed, the hot weather in Texas meant that team members often left the door open for ventilation, allowing the damp, salty air to circulate through. Knowledge of the region, and understanding of how people conduct their responsibilities, allowed us to quickly identify the challenge and develop a solution.

The final tool in the lubricant champion’s belt is the lubricant analysis routine—a fundamental shift in how preventative maintenance is conducted in your facility. Rather than sticking to a routine, calendar-based oil drain interval, routine lubricant analysis operates like a blood test for your machine. In it, a sample is taken from key points in your facility and then sent to a lab where experts analyze the oil using sophisticated machinery to identify contaminants, determine wear and viscosity levels, and diagnose how much longer your machine can operate before the next change.

On one occasion, our experts identified water in the lubricant, which pointed to a contamination problem. However, since our experts also identified copper and sodium, we were able to narrow our theory even further and conclude that there might be a cooler leak. Turns out we were right!

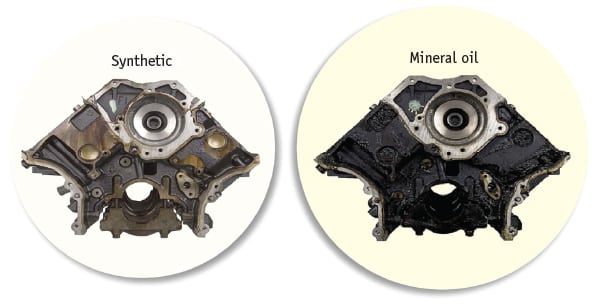

Routine lubricant analysis allows your lubricant champion to proactively prevent failures by precisely resolving them. For example, if the analysis reveals water in your oil, you can take the appropriate measures—be that an oil change or a vacuum dehydrator—to resolve the challenge quickly and efficiently, rather than simply swapping out your product for a fresh batch and hoping for the best. Advanced oil analysis is even better, providing insights into longer-term and more challenging potential issues, like varnish, and offering a clear plan for prevention or mitigation.

The immediate advantages of implementing a lubricant analysis routine are almost always increased oil drain intervals (ODIs) and peace of mind, but the long-term benefits can be even greater. Once you have years of data collected, you are even more empowered to interpret results and implement solutions with the specific nuances and trends of your own components. These insights, combined with an adherence to original equipment manufacturer (OEM) guidelines and standards, can provide a more comprehensive understanding of your components that will empower you to get the most out of your equipment.

If you properly supply your champion with these three tools—high-quality products, expert support, and a lubricant analysis routine—you can expect improved uptime, extended lifetime for your equipment, increased efficiency, and an easier time achieving your goals. But more than that, you can be sure that you are getting the most out of your team members’ time and effort, bringing your facility closer to achieving a level of efficiency, reliability, and productivity that you can all be proud of.

—Joel Scarbrough is lubrication engineer for central, east, and south Texas at ExxonMobil.