Selecting the best fuel gas compressor technology is critical for plant performance and economics. This comprehensive comparison examines three compressor types to help power plant designers choose the optimal solution for their specific operational requirements and duty cycles.

The rapid expansion of renewable energy has turbocharged the need for flexible, gas-fired generation. Gas turbine plants today operate across a wide range of modes—from fast-start simple cycle peaker units to high-efficiency combined cycle plants and cogeneration systems.

Across all these applications, the role of the fuel gas compressor is crucial: to deliver pipeline gas at the correct pressure and flow conditions required by the turbine. Turbine fuel gas pressures may range from 200 psig to 900 psig, though some advanced turbines and high-altitude applications could require higher.

To achieve this, the industry heavily relies on compressor designs governed by three American Petroleum Institute (API) standards:

- ■ API 619, which is focused on rotary screw compressors.

- ■ API 618, which addresses reciprocating compressors.

- ■ API 617, which covers centrifugal compressors.

Each of these technologies offers specific performance characteristics that make them more or less suitable depending on plant type, operational duty cycle, flow and pressure needs, and lifecycle cost priorities.

Fuel Gas Compression Needs by Plant Type

Simple Cycle Peaker Plants. Simple cycle turbines often run for short periods to supply peak grid demand. Compressors for peakers must be capable of fast startup, frequent cycling, and wide turndown to match varying turbine loads.

Combined Cycle Power Plants (CCPPs). Combined cycle plants may operate continuously or follow load, depending on market demand. They require compressors that deliver stable fuel pressure across variable flow conditions, with a focus on low maintenance and high reliability.

Cogeneration or Combined Heat and Power (CHP) Plants. Cogeneration systems provide both electricity and thermal energy (often steam) to industrial users. Fuel gas compression requirements vary depending on how closely power and thermal loads track each other, requiring flexible and reliable compressor operation.

API Standards and Compressor Types

API 619—Rotary Screw Compressors. A machine built of meshed helical rotors that draws gas inward and presses it forward. It is steady, pulse-free, and practical, a workhorse preferring a life of action to one of rest. The screw can start quickly when the plant calls upon it. It can handle a little surprise. It can turn up or down as needed, from full effort to a modest trickle, with no complaint. Not the largest, nor the strongest, but the most adaptable (Figure 1). And in the world of gas-fired power, adaptability is a treasure.

|

|

1. Oil-injected screw compressors for a natural gas combined cycle power plant in Mexico (capacity: 2,698 cubic feet per minute [CFM], suction pressure: 287.4 psia, discharge pressure: 644 psia, driver: 5,100 hp). Courtesy: Kobelco Compressors America Inc. |

Advantages:

- ■ Compact skid-mounted systems.

- ■ Rapid response to load variations is possible via built in slide valve.

- ■ Lower maintenance than reciprocating or centrifugal.

- ■ Well-suited to cycling and flexible operation.

Limitations:

- ■ Oil carryover needs to be considered for downstream requirements in case of using oil-injected (wet screw) type.

- ■ Oil selection for wet screws should be carefully considered based on gas composition.

API 618—Reciprocating Compressors. Reciprocating compressors use pistons to compress gas in discrete strokes, offering high-pressure capability with customizable stages. It demands care, regular and thorough. But when treated well, it delivers what others cannot: ultra-high pressure, and the ability to compress nearly anything that might find its way through the pipes. It is a specialist, and specialists are precious in their way.

Advantages:

- ■ Capable of handling low suction pressure.

- ■ Suitable for very high discharge pressure requirements.

- ■ Oldest compressor technology, and so, familiarity tends to be high.

Limitations:

- ■ Higher maintenance due to many moving parts.

- ■ Larger footprint and requires a more robust foundation.

- ■ Less suited to rapid cycling or daily start-stop.

API 617—Centrifugal Compressors. Centrifugal compressors are dynamic machines that increase gas pressure by imparting kinetic energy through spinning impellers. Where the rotary screw works by force and the reciprocating by breath, the centrifugal works by flight—spinning impellers that fling gas outward, trading velocity for pressure. It loves flow; large, steady, unbroken flow. If given that, it proceeds reliably, a marvel of engineering grace.

However, surge is a critical operating limit in centrifugal compressors, occurring when the flow through the compressor drops below a stable threshold. At low flow rates, the pressure generated by the impellers can no longer overcome the downstream system resistance, causing flow to momentarily reverse or oscillate. This results in damaging vibrations, high mechanical stresses, and potentially catastrophic failure if not controlled.

To prevent surge, centrifugal compressors must operate above a defined minimum flow, often maintained by an anti-surge control system and/or recycle loop. These are generally not suited for applications requiring wide turndown below 20% to 30% of design flow. Proper sizing and control are essential to ensure reliable, surge-free operation.

Advantages:

- ■ High efficiency at baseload conditions.

- ■ Heavier MW gases handled easily.

- ■ Fewer wearing parts than reciprocating.

Limitations:

- ■ Turndown range is limited and not stepless.

- ■ Not ideal for frequent cycling, best performance is seen at steady-state operation.

- ■ Less efficient at handling gases with lower molecular weight (hydrogen, helium, etc.).

- ■ Requires extensive auxiliary systems (coolers, seal gas, and lube systems).

Comparative Summary

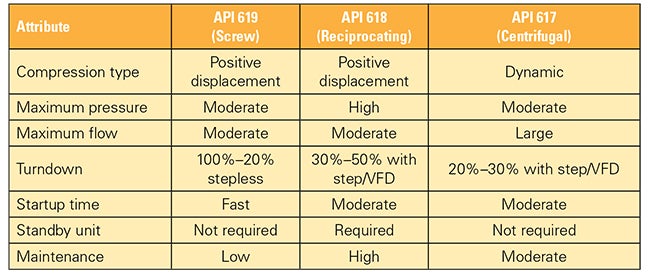

Choosing the right fuel gas compressor is not unlike choosing companions for a long journey (Table 1). Pick the wrong one, and the road becomes hard. Pick well, and things move with ease.

|

|

Table 1. Choosing the best compressor for an application requires considering several attributes. Note: VFD = variable frequency drive. Source: Kobelco Compressors America Inc. |

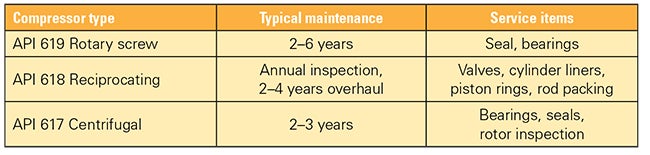

Maintenance and lifecycle differences are also important to consider when selecting the best compressor for an application. Compressor reliability is essential to avoid forced outages and maintenance profiles also differ significantly (Table 2).

|

|

Table 2. Typical maintenance requirements and common service items are noted for the three compressor types. Source: Kobelco Compressors America Inc. |

While major maintenance should not be needed as often, the standard daily and weekly upkeep necessary to maintain a reciprocating compressor is steep. Major overhauls will also have a longer schedule and require more labor when compared against the other compressor types.

Centrifugal compressors don’t tend to require the same upkeep as a reciprocating compressor, but surge can impact its maintenance needs significantly. Surge is one of the most damaging operating conditions for centrifugal machines.

As previously alluded to, when flow drops below the stable limit, momentary flow reversal and violent pressure oscillations can occur, leading to severe vibration, mechanical fatigue, and ultimately premature wear or failure of critical components, including bearings, seals, and impellers. Even brief or infrequent surge events can significantly reduce the expected maintenance interval and increase lifecycle costs.

To ensure long-term reliability, centrifugal compressors must be operated above their surge threshold, with proper sizing, surge margin, and effective anti-surge controls in place. Plants with highly variable load profiles or frequent cycling should carefully evaluate these factors, as surge-related maintenance is one of the key risks when applying centrifugal compressors for a flexible power generation service.

Overall, oil-injected screw compressors tend to offer the lowest total maintenance cost and shortest downtime, making them attractive for flexible, frequently cycled power plants.

Choosing the Best Option

Fuel gas compressor selection is a critical aspect of designing gas-fired power plants. The right choice depends on operational factors, such as:

- ■ Required discharge pressure and flow.

- ■ Duty cycle (baseload vs. cycling).

- ■ Plant size and configuration.

- ■ Lifecycle maintenance strategy.

API 619 screw compressors—offering moderate discharge pressure (as high as 1,500 psig) and 100% to 20% stepless turndown—are increasingly popular due to their simplicity, flexibility, and resilience under punishing conditions. API 618 reciprocating compressors remain relevant for specialty high-pressure applications. API 617 centrifugal compressors are well-suited to baseload projects where stable, large flow is likely.

Ultimately, selecting a fuel gas compressor for a power plant is a lot like picking the right tool from your toolbox. You wouldn’t use a sledgehammer to adjust a fine valve, or a precision wrench to break up concrete. Likewise, rotary screw compressors are your reliable multi-tool; adaptable, efficient, and easy to handle for flexible plant operations. Reciprocating units are the heavy-duty impact wrenches: powerful, but they require respect and frequent maintenance. And centrifugal compressors? They’re your industrial-grade conveyor, built to move serious flow, as long as you don’t expect it to stop and start all day.

The right choice makes your project smoother, reliable, and a lot less costly down the road. In all cases, it is wise to remember that these machines, while made of steel, lubricated with oil, and painstakingly designed, are also something more: they are the heart breathing life into your turbines. Choose them as you would choose any good heart—for the long term.

—J. Baranowski is a sales representative and Takahiro Matsuura is technical sales manager with Kobelco Compressors America Inc.