Water

-

Hydro

Wave Energy Device to Tap Marine Energy in Gulf of Mexico

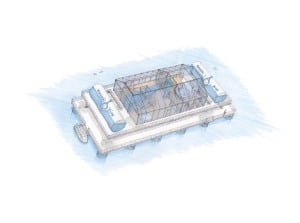

The U.S. Army Corps of Engineers earlier this year awarded its first Section 10 permit ever to a commercial wave-powered demonstration facility planned for installation in the Gulf of Mexico. The novel offshore platform, dubbed the SEADOG, will use a buoy and piston mechanism combined with a water wheel to generate electricity and desalinate water.

-

Water

ReACT Reduces Emissions and Water Use

Regenerative activated coke technology (ReACT) is an integrated multipollutant control approach that removes SOx, NOx, and Hg from coal-fired plants by adsorption with activated coke to attain emissions levels found at natural gas–fired plants. One big advantage of this technology is that it uses only a fraction of the water used by conventional wet flue gas desulfurization. A recent license agreement brings this technology to the U.S.

-

Water

Circulating Fluid Bed Scrubbers Bridge the Gap Between Dry and Wet Scrubbers

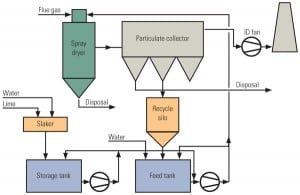

Circulating fluid bed (CFB) dry scrubbing technologies provide distinct advantages over conventional spray dryer absorber scrubbers for removing SO2 from flue gases. The CFB also competes well against wet limestone flue gas desulfurization processes typically favored for large boilers firing high-sulfur coals. With high SO2 removal rates in a dry treatment process, the CFB scrubber appears to be the best of both technologies: a water-stingy scrubber with high SO2 removal rates.

-

Water

Appraising Our Future Cooling Water Options

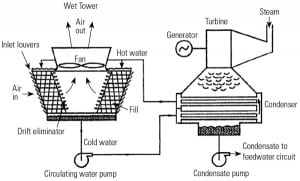

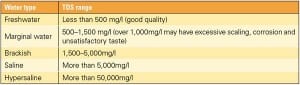

Ensuring the availability of water for power plants is a matter of both water quantity and quality. As freshwater becomes less available for power plant use, new supplies from marginal or impaired sources will require new cooling technologies. We look at cooling equipment options and how water availability and quality affect cooling system design and cost.

-

Coal

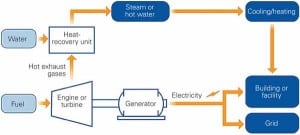

Adding Desalination to Solar Hybrid and Fossil Plants

Shrinking water supplies will unquestionably constrain the development of future power plants. A hybrid system consisting of concentrated solar thermal power and desalination to produce water for a plant, integrated with a combined cycle or conventional steam plant, may be the simple solution.

-

Water

Sub-Sea Water Treatment System Provides Reliable Supply for the Huarun Power Plant

River deltas experience extreme seasonal changes in water quality that perplex conventional water treatment systems. Industrial development in China, including new power plants, has spurred the development of desalination processes that have tamed these brackish water sources to provide a virtually unlimited supply of boiler-quality water.

-

Water

Strategies to Reduce Sulfuric Acid Usage in Evaporative Cooling Water Systems

Concentrated sulfuric acid is often used to prevent calcium-based scale formation on condenser and heat exchanger tube surfaces in power plant evaporative cooling water systems. Unfortunately, the chemical’s price has jumped more than 300% over the past three years. If the rising cost of water treatment has you under the budget gun, here are some alternative strategies that can reduce or even eliminate your sulfuric acid usage.

-

Coal

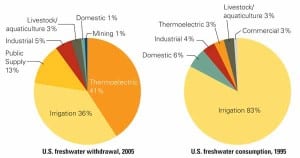

Determining Carbon Capture and Sequestration’s Water Demands

The U.S. Department of Energy’s National Energy Technology Laboratory is pursuing a new integrated energy-water R&D program that addresses water management issues relative to coal-fired power generation that takes into account the major impacts of CCS on water use. The goal of this research is to promote more efficient use of water in power plant operations and increase the availability of heretofore unusable waters for power plant use. Those practices can mitigate the impacts of CCS on power plant water use and allow for continued development of energy resources.

-

Water

Harnessing Energy from Upward Heat Convection

The atmospheric vortex engine exploits the natural energy content of the vortex produced during upward heat convection in the atmosphere. The heat source can be solar energy, warm sea water, warm humid air, or even waste heat rejected in a cooling tower. When mature, the technology — currently in the small-scale testing phase — promises to be an efficiency game-changer for fossil-fired power plants.

-

Coal

Plant Efficiency: Begin with the Right Definitions

The race is on to claim the title of "most efficient coal-fired power plant" on the planet. However, it’s tricky identifying finalists because of the widespread misuse of the term "efficiency" and all those nagging assumptions. Let’s first establish clear definitions and then identify the title contenders.