Waste to Energy

-

Coal

Consolidation, Market Distortions Underlie Remarks by Industry Executives

If you needed additional proof that the power industry is changing, the ELECTRIC POWER keynote and panel discussions over the past few years have provided it—top-of-mind issues have been significantly different each year. For the 2011 keynote speaker and panelists, the challenges of reliability, regulatory compliance, financing, and getting the fuel mix right took center stage. In the wake of Japan’s nuclear crisis, safety also featured prominently.

-

O&M

Solid Fuels: Moving Material and Managing Emissions

In today’s solid-fueled power plant, managing emissions and moving materials more defines the task than the traditional work of making megawatts. That’s the message that emerged from the coal and solid fuels track at this year’s ELECTRIC POWER.

-

Solar

Utilities Increase Renewable Energy Capacity

Driven by state RPS requirements and the desire to diversify their energy sources, U.S. utilities continue to add more renewable power to their generation portfolios. As a result, they must deal with a number of important issues, including resource availability that varies geographically.

-

Coal

Spain: A Renewable Kingdom

Spain has served as both exemplar and scapegoat when it comes to renewable energy policy. Though power policy must necessarily accommodate specific national resources and goals, Spain’s experience as an early and eager adopter of renewable energy technologies and subsidies is a cautionary tale of how the best intentions can have unintended consequences.

-

Coal

Biomass Cofiring: A Promising New Generation Option

Biomass cofiring has the potential to cut emissions from coal-fueled generation without substantially increasing costs or infrastructure investments. Research shows that when implemented at relatively low biomass-to-coal ratios, energy consumption, solid waste generation, and emissions are all reduced. However, mixing biomass and coal does create some challenges that must be addressed.

-

Coal

Designing Fuel Systems for Large Biomass Plants

Compared with other solid fuel–fired plants, the systems and components required for handling and processing biomass appear quite familiar, but important fuel differences must be considered. A successful biomass plant design must provide flexibility for handling the expected wide range of biomass fuel properties and characteristics.

-

Coal

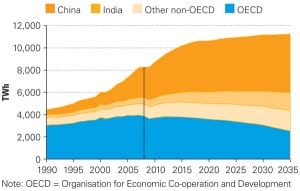

IEA: Global Power Demand to Surge 2.2% Annually Through 2035

Though electricity generation has entered a key period of transition—as investment shifts to low-carbon technologies—world electricity demand is set to grow faster than any other “final form of energy,” the International Energy Agency (IEA) says in its latest annual World Energy Outlook.

-

Waste to Energy

Top Plant: Colmac Energy Inc.’s Biomass- Fueled Power Plant, Mecca, California

The 47-MW Colmac Energy facility is the largest biomass-fueled power plant in California. Colmac operates with a capacity factor consistently in the 92% to 95% range and at a net plant heat rate comparable to waste coal facilities. Colmac Energy has demonstrated that biomass plants using urban wood wastes as fuel can generate significant environmental benefits, including reduced air pollutants from open-air burning and lowered demand for landfill space.

-

Waste to Energy

Top Plant: Kajang Waste-to-Energy Plant, Semenyih, Malaysia

At Malaysia’s first waste-to-energy plant, municipal solid waste (MSW) is converted into refuse-derived fuel for use in an integrated steam power plant. This facility was designed to achieve the twin objectives of environmentally friendly MSW disposal and generating renewable power.

-

Waste to Energy

Top Plant: Kaukaan Voima Oy Biomass-Fired Power Plant, Lappeenranta, Finland

Located in the heavily forested country of Finland, the Kaukaan Voima biomass-fueled power plant produces process steam and electricity for UPM’s Kaukas pulp and paper mill as well as electricity and district heating for Lappeenrannan Energia, a city-owned power company. Launched in 2009, the plant can provide 125 MW of electricity, 110 MWth of district heat, and 150 MWth of process steam thanks to one of the world’s largest wood-fired fluidized bed boilers.